Preparation method of self-lubrication material nanometer calcium fluoride for ceramic cutting tool

A technology of self-lubricating materials and ceramic cutting tools, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve the problems that cannot be used to prepare self-lubricating cutting tool materials, and achieve short preparation time and Easy to operate, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

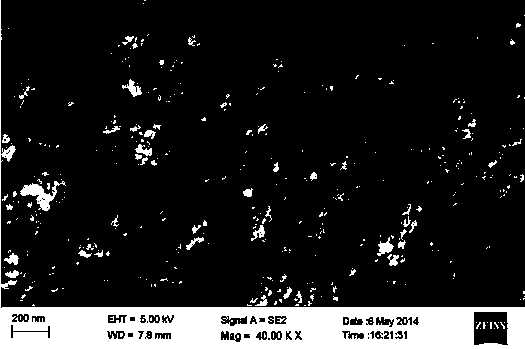

Image

Examples

Embodiment 1

[0025] Weigh 12.8g of calcium nitrate and 5.05g of ammonium fluoride according to the molar ratio of 1:3.0, put them into beakers respectively, add 25ml of distilled water and 25ml of absolute ethanol respectively, shake well and dissolve, and obtain the pre-prepared calcium nitrate and ammonium fluoride solution; weigh 0.75g of PEG6000, add the pre-prepared ammonium fluoride solution, ultrasonically disperse for 15 minutes, and dissolve it completely to obtain a composite solvent of polyethylene glycol and ammonium fluoride solution, wherein polyethylene glycol The weight concentration of alcohol PEG6000 is 1.5%.

[0026] The magnetic stirring temperature was set at 35°C. Under the magnetic stirring condition, the calcium nitrate solution was quickly dropped into the dispersed ammonium fluoride solution (the dropping speed was 10ml / min) from the separatory funnel, and reacted for 5 minutes. The reacted solution was taken out for ultrasonic dispersion for 5 min, and left...

Embodiment 2

[0029] Weigh 6.4g of calcium nitrate and 2.525g of ammonium fluoride according to the molar ratio of 1:3.0, put them into beakers respectively, add 12.5ml of distilled water and 12.5ml of absolute ethanol, shake well and dissolve, and obtain the pre-prepared Calcium nitrate and ammonium fluoride solution; weigh 0.5g of PEG6000, add the pre-prepared ammonium fluoride solution, ultrasonically disperse for 15 minutes, and dissolve it completely to obtain a composite solvent of polyethylene glycol and ammonium fluoride solution, wherein poly The weight concentration of ethylene glycol PEG6000 is 2%.

[0030] The magnetic stirring temperature was set at 20°C. Under the magnetic stirring condition, the calcium nitrate solution was dropped into the dispersed ammonium fluoride solution from the separatory funnel (the dropping speed was 1ml / min) and reacted for 5 minutes. The reacted solution was taken out for ultrasonic dispersion for 5 min, and left to age for 48 h. Centrifuge a...

Embodiment 3

[0033] Weigh 12.8g of calcium nitrate and 5.05g of ammonium fluoride according to the molar ratio of 1:3.0, put them into beakers respectively, add 25ml of distilled water and 25ml of absolute ethanol respectively, shake well and dissolve, and obtain the pre-prepared calcium nitrate and ammonium fluoride solution; weigh 0.5g of PEG6000, add the pre-prepared ammonium fluoride solution, ultrasonically disperse for 15 minutes, and dissolve it completely to obtain a composite solvent of polyethylene glycol and ammonium fluoride solution, wherein polyethylene glycol The weight concentration of alcohol PEG6000 is 1%.

[0034] The magnetic stirring temperature was set at 35°C. Under the condition of magnetic stirring, the calcium nitrate solution was dropped into the dispersed ammonium fluoride solution from the separatory funnel (the dropping speed was 30ml / min) and reacted for 5 minutes. The reacted solution was taken out for ultrasonic dispersion for 5 min, and left to age for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com