Lower-film-walking packing mechanism

A packaging and film-type technology, applied in packaging, transport packaging, transportation and packaging, etc., can solve the problems of increased production cost, roll film weight, impracticality, etc., and achieve stable operation, fast and smooth transportation, simple and practical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

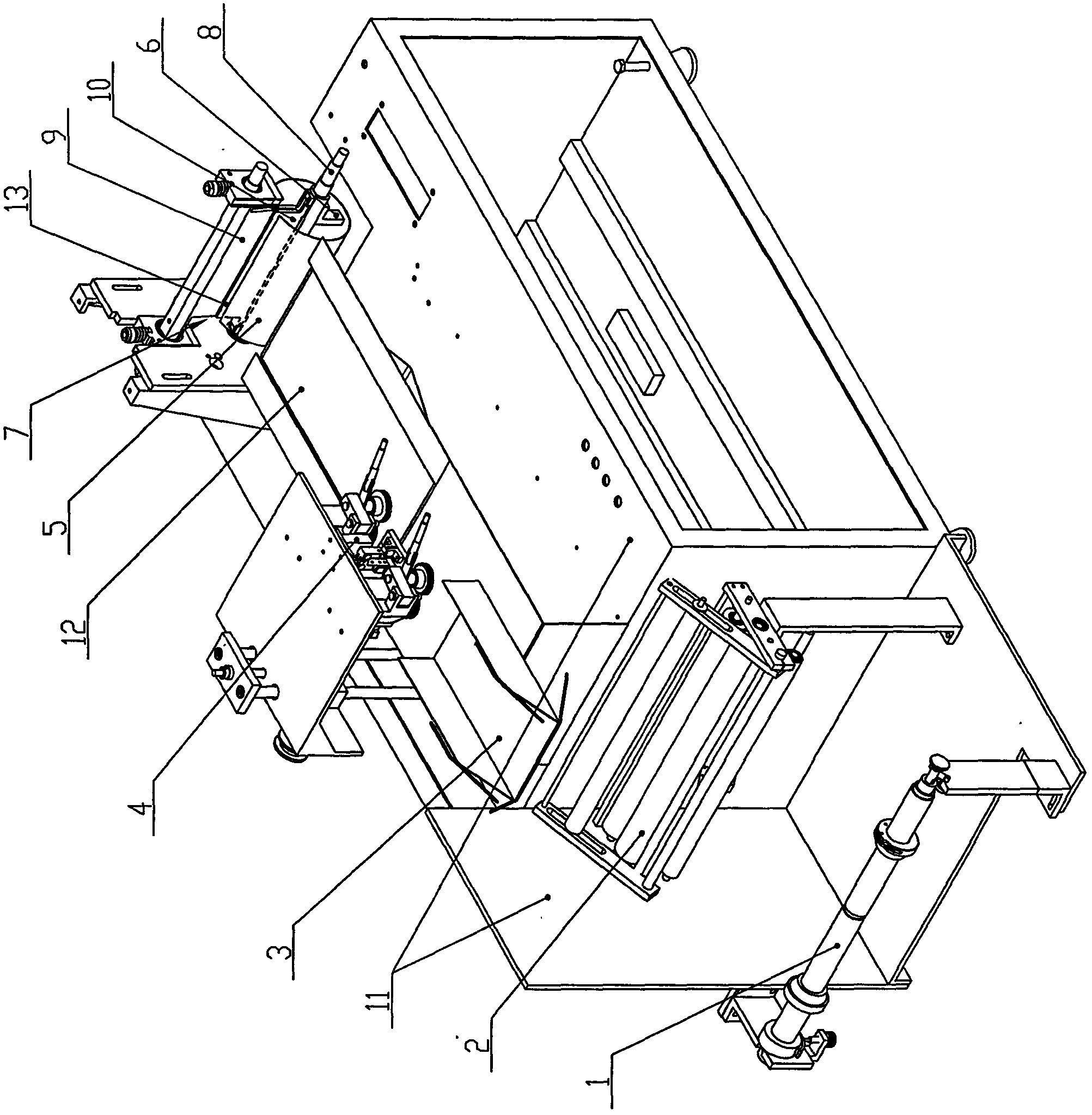

[0007] Reference figure 1 It can be seen that the bottom film packaging mechanism of the present invention includes a frame 11, an unwinding device 1, a forming device 3, a middle sealing device 4 (which also has the function of pressing and releasing the gas in the film, with the sealing roller facing downward), and a sealing and cutting device 7. , The unwinding device 1 is installed in the lower part of the frame 11, the opening of the forming device 3 faces upwards, and the sealing and cutting device 7 (for rotary heat sealing and cutting) has a knife seal shaft 8 supported by a fixed seat 6 Reel 5 (leave a gap 13).

[0008] Wherein: a traction device 2 is installed on the frame 11 and between the unwinding device 1 and the forming device 3, and is installed on the frame 11 and between the forming device 3 and the sealing and cutting device 7. There is a conveying device 12, the sealing and cutting device 7 includes a knife sealing shaft 8, an upper sealing knife 9, a rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com