Screw material conveyor

A technology for conveyors and conveying mechanisms, applied in the directions of transportation and packaging, loading/unloading, containers, etc., which can solve the problems of high warehouse pressure, increased warehouse pressure, and high energy consumption, and achieve low warehouse pressure, low resistance feeding, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

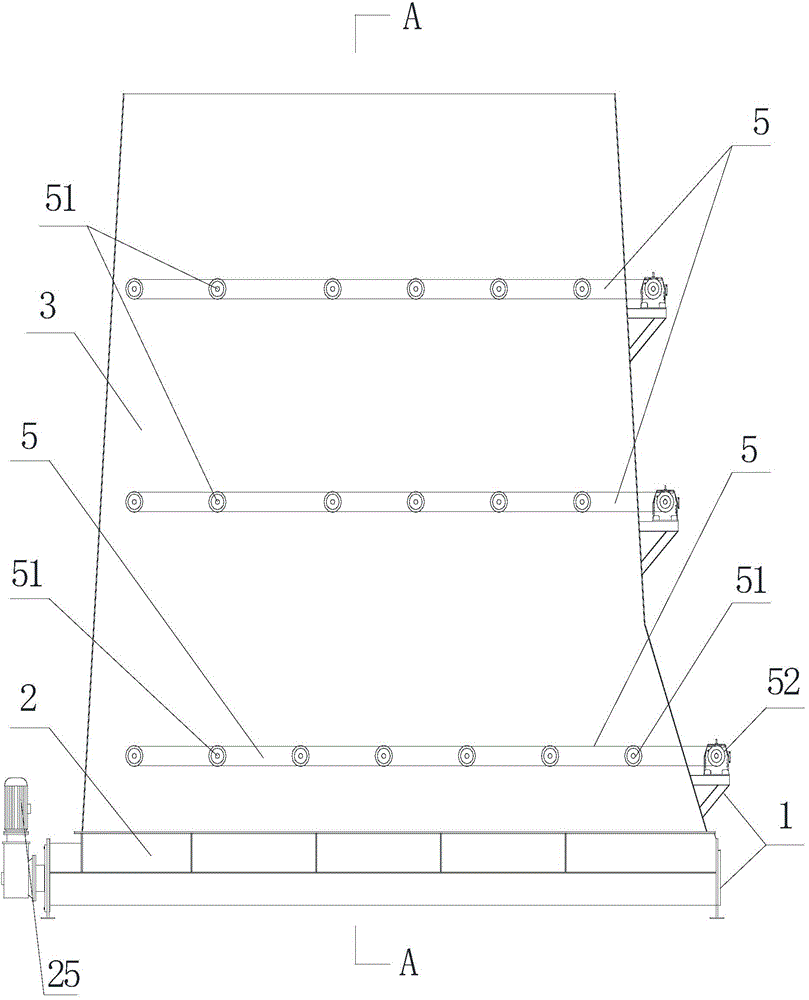

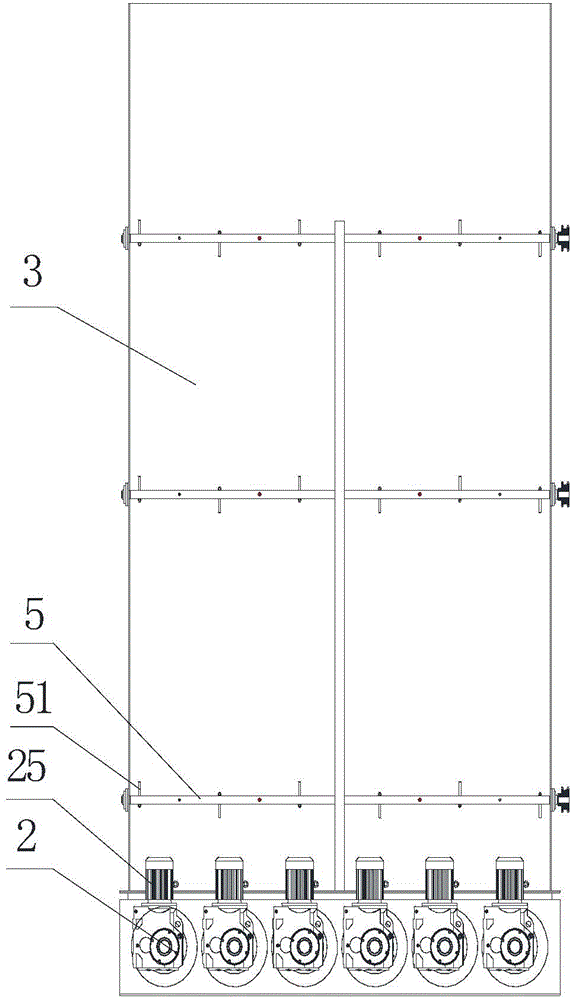

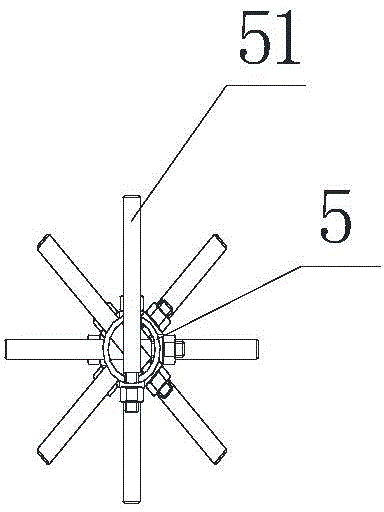

[0017] Such as Figures 1 to 5 Shown is a kind of embodiment of screw material conveyor of the present invention, and it comprises body 1, and described body 1 is provided with feed bin 3, and the bottom of feed bin 3 is provided with conveying mechanism 2 in body 1, and conveying mechanism 2 has conveying screw 22. There is a stirring shaft 5 inside the silo 3, and a motor 52 that drives the stirring shaft 5 to rotate is provided on the frame 1. A number of stirring rakes 51 are arranged on the stirring shaft 5, and the stirring rakes 51 are eccentrically installed on the stirring shaft. On the shaft 5, the axial direction of the stirring shaft is perpendicular to the axial direction of the conveying screw, the conveying mechanism 2 includes a housing 21, an arc-shaped groove is arranged in the housing 21, and the conveying screw 22 is shaftless Screw, the conveying screw 22 is located in the groove, and the housing 21 is provided with anti-arching parts for preventing the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com