Aluminizing film winding device

A technology of winding device and aluminized film, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of loose or bulging winding film, long time-consuming, affecting production efficiency, etc., and achieves guaranteed Winding, avoiding the effect of arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

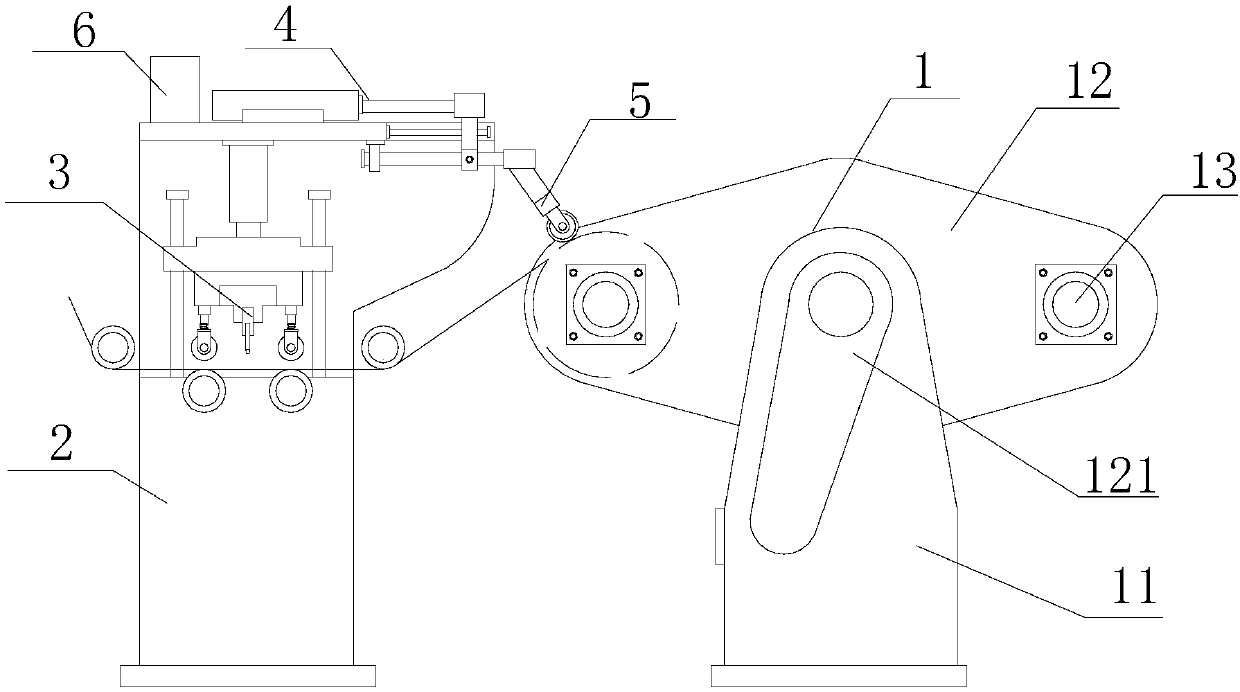

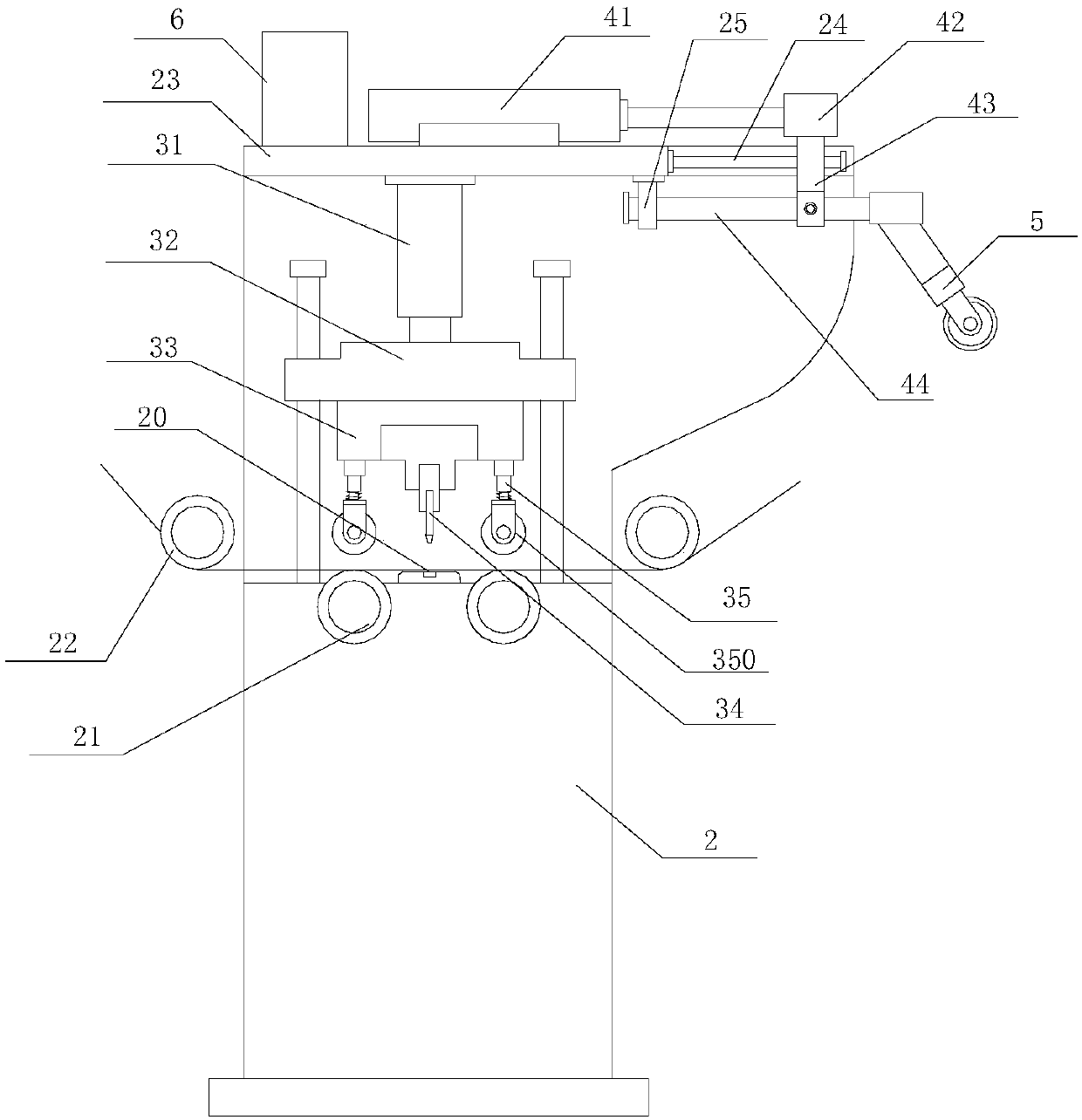

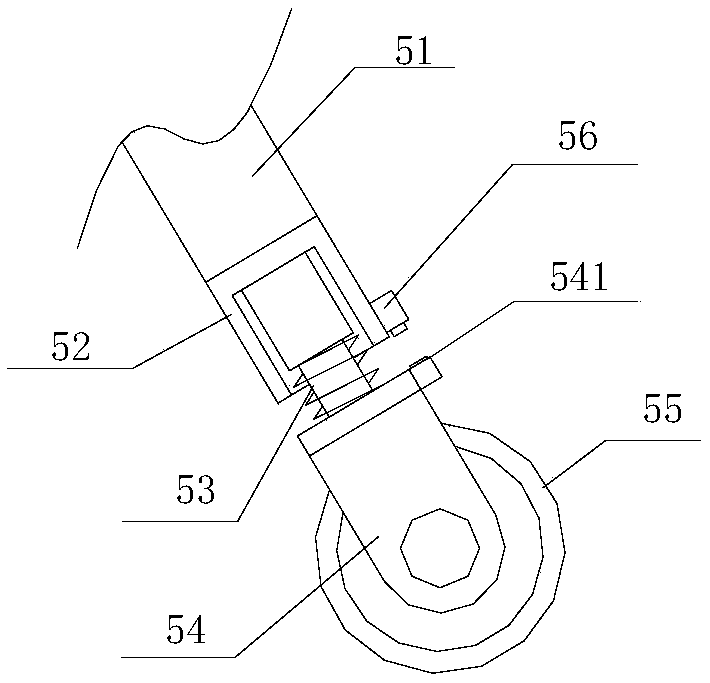

[0015] refer to Figure 1 to Figure 3 , an aluminized film winding device of the present invention is characterized in that: it comprises a winding device 1, a frame 2, a cutting device 3, an adjustment driving mechanism 4, a winding pressure roller mechanism 5 and a control system 6, and the winding The device 1 is provided with a transposition rotating arm 12, and the rewinding roller assembly 13 is symmetrically installed on the transposition rotating arm 12, and the support seat 23 is provided on the said frame 2, and a cutting machine is installed below the support seat 23. Device 3, a cutting knife 34 is installed below the cutting device 3, a cutting roller assembly 35 is arranged symmetrically on both sides of the cutting knife 34, and the adjustment driving mechanism 4 is installed on the support base 23, and the adjustment driving mechanism 4 The mechanism 4 is provided with a second driving cylinder 41, and the second driving cylinder 41 is used to control the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com