Device for maintaining temperature of bulk material

A loose material, temperature regulation technology, applied in the direction of tubular elements, heat exchange equipment, fixed tubular conduit components, etc., can solve the problems of unfavorable cleaning, high structure height, poor efficiency and construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

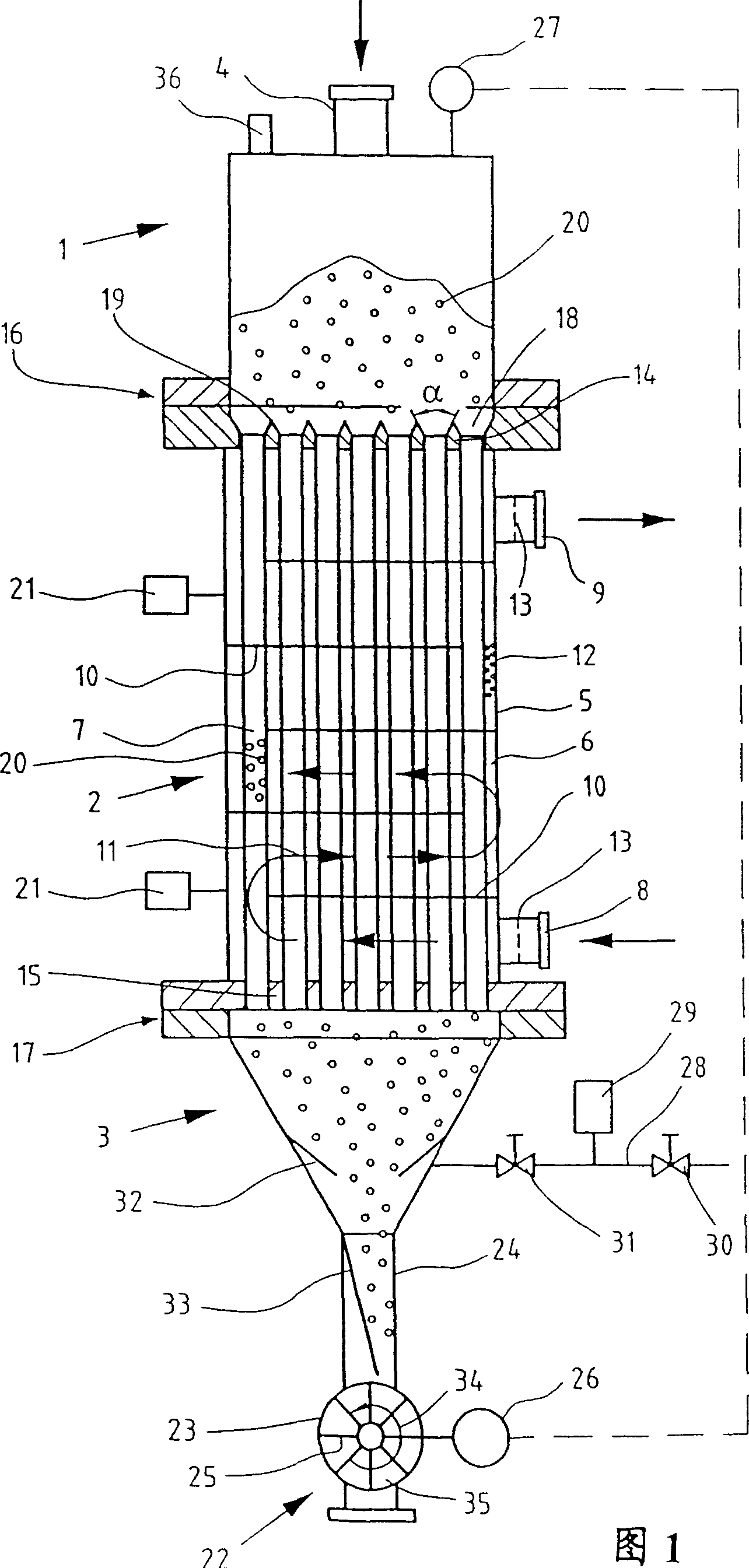

[0024] The device for tempering bulk material shown in FIG. 1 has an upper buffer section 1 , a central heat exchange section 2 and a lower discharge section 3 . The segments 1 , 2 , 3 each have a circular cross section. The shell-shaped, substantially closed buffer section 1 is provided with an upper supply connection 4 for conveying the bulk material to be tempered.

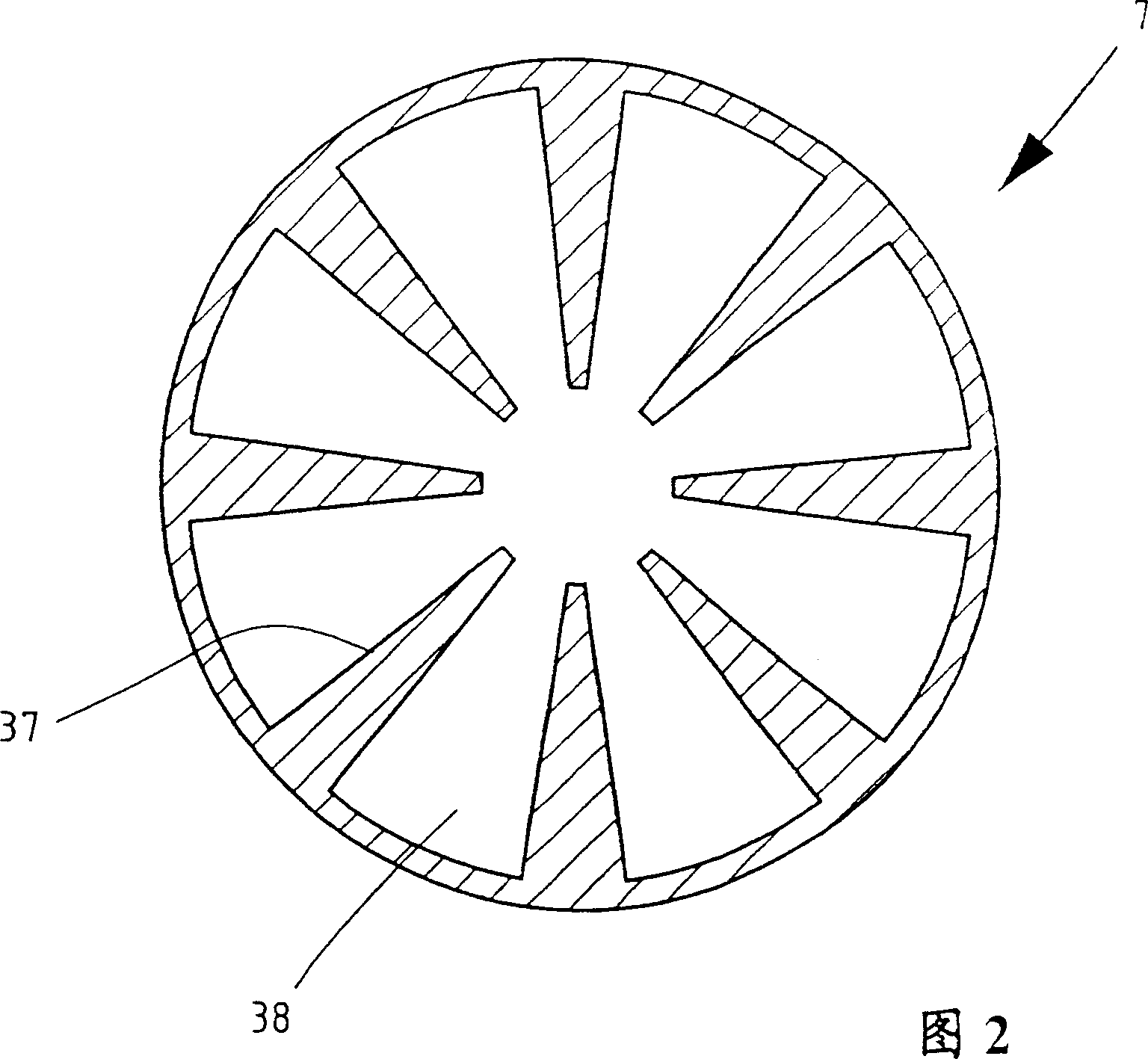

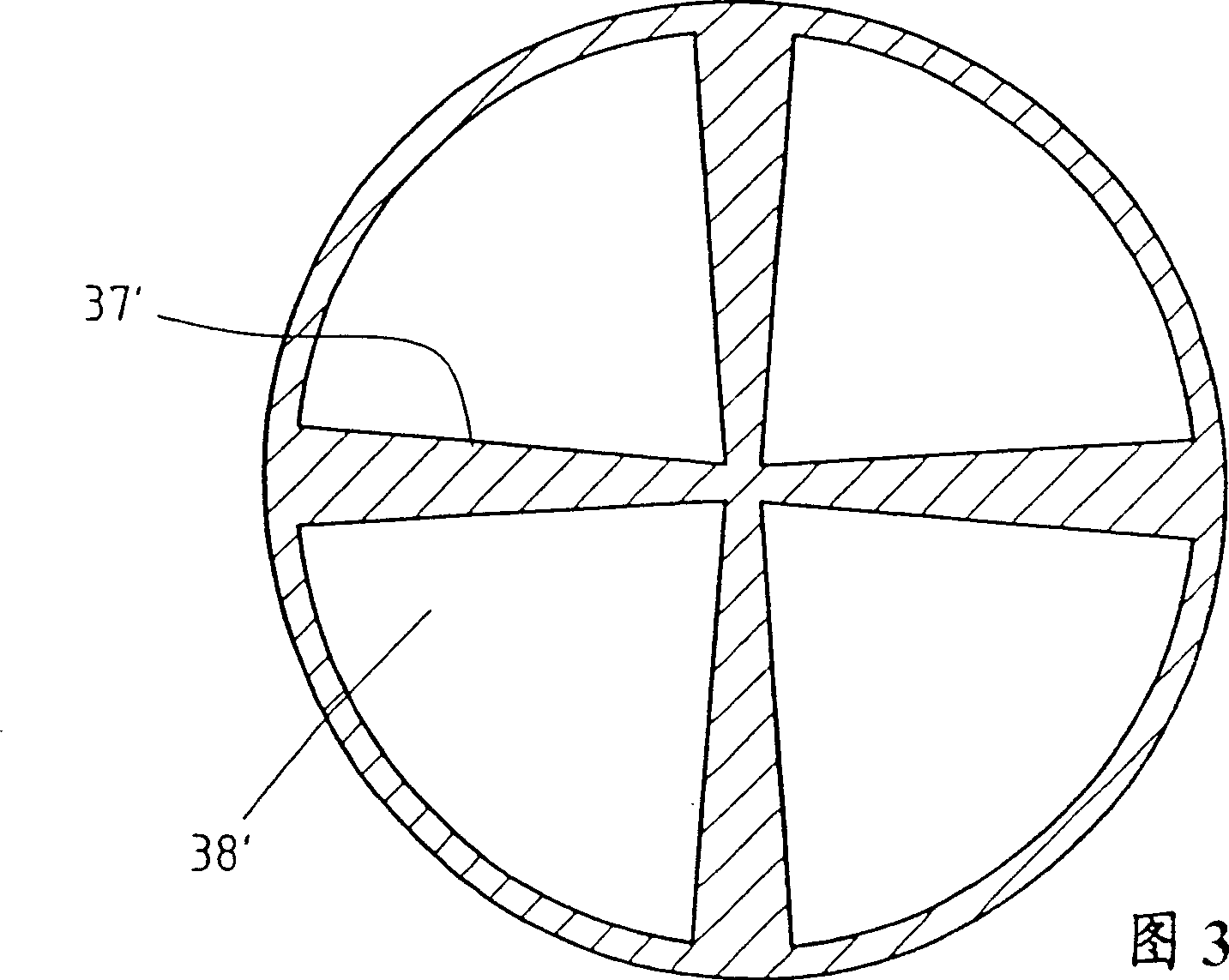

[0025] The heat exchange section 2 has a housing 5 , in an interior 6 of the housing, mutually parallel heat exchanger tubes 7 are arranged at a distance from each other. That is, the inner cavity 6 is a heat exchange cavity.

[0026] Adjacent to the discharge section 3 , a supply connection 8 for the heat transfer fluid opens into the interior 5 of the housing 5 of the heat exchange section 2 . Adjacent to the damping section 1 , a discharge connection 9 leads out of the interior 6 of the housing 5 . Deflector plates 10 are mounted in the interior space 6 at a distance from each other transversely to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com