Repair method of flushing head or exhaust head of steel pipe hydraulic testing machine

A technology of a hydraulic testing machine and a repairing method is applied in the repairing field of the flushing head or the exhausting head of the steel pipe hydraulic testing machine, which can solve the problems of obstruction, loss of on-site production of steel pipes, scrapping of the filling head and the exhausting head, and the like. The effect of ensuring utility, saving production costs and avoiding scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

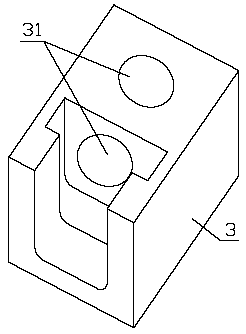

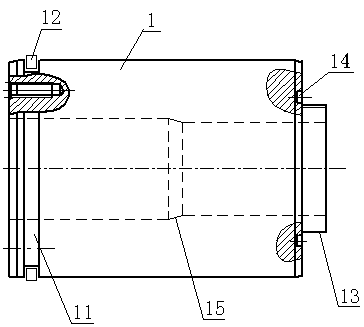

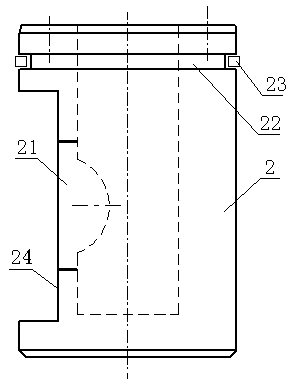

[0018] Such as figure 2 , image 3 and Figure 4 As shown, the method for repairing the flush head or the exhaust head of the steel pipe hydraulic testing machine of the present invention comprises the following steps:

[0019] Step 1, enlarging the diameter of the cross inner hole of the flushing head or exhaust head body 3 by machining, and milling the bottom of the blind hole in the cross inner hole to a depth of 25-35 mm;

[0020] Step 2, making the first hollow cylindrical head 1 and the second hollow cylindrical head 2, the front end of the first hollow cylindrical head 1 is provided with a first sealing groove 11, the first sealing ring 12 is arranged in the first sealing groove 11, and the first hollow cylinder The tail end of the head 1 is provided with an external thread 13, the end surface of the external thread 13 is provided with a second sealing groove, and the end face sealing ring 14 is arranged in the second sealing groove, and the side of the second hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com