Induction type lifting sound barrier system and working method thereof

A working method and sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of not being well integrated into the environment, short service life of the sound barrier, and affecting the vision of residents along the line, so as to achieve environmental friendliness and harmony, reduce Damage probability, fatigue damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

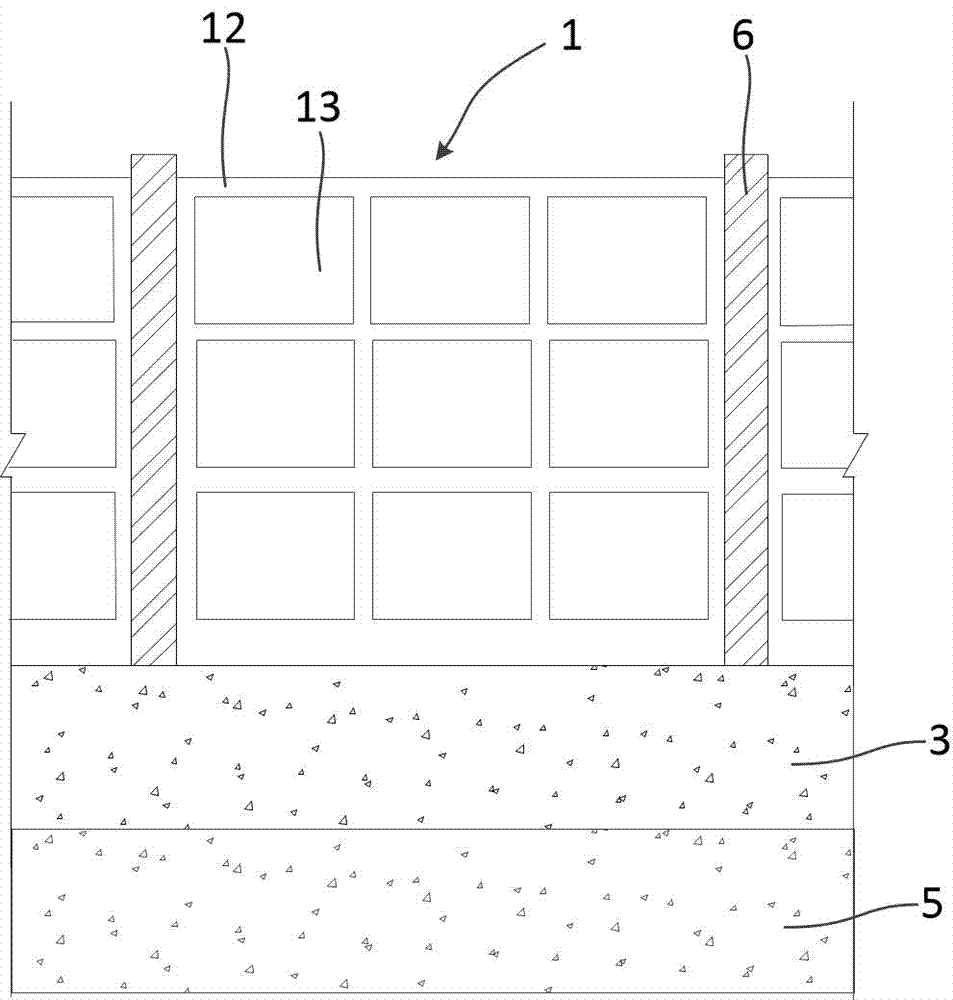

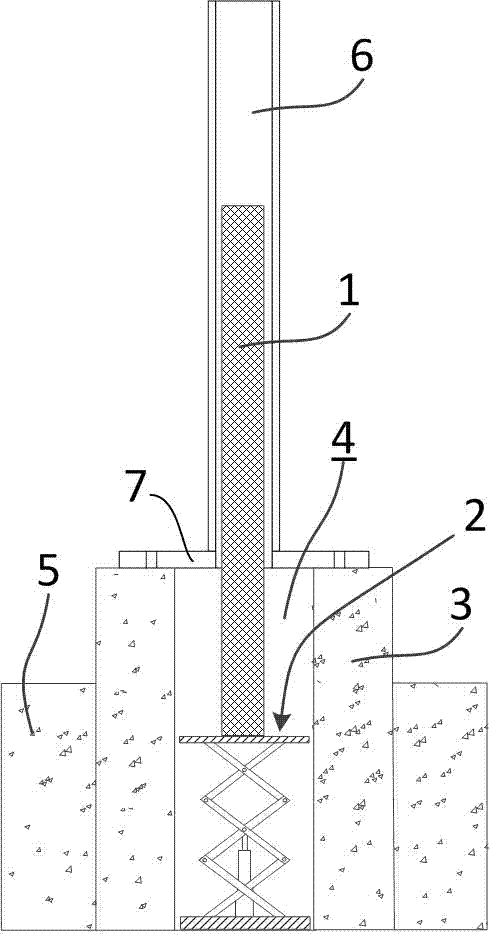

[0033] Embodiment 1: as figure 1 , 2 As shown, this embodiment specifically relates to an inductive lifting sound barrier system, which includes a sound barrier plate 1, a lifting mechanism 2, and a base 3; the base 3 is provided with an accommodating groove 4 for accommodating the sound barrier plate 1; The mechanism 2 is arranged between the base 3 and the sound barrier panel 1, and is used to drive the sound barrier panel 1 up and down.

[0034] Such as figure 2 As shown, the base 3 is arranged on the side of the railway, and the bottom of the base 3 is connected with the lower foundation 5; the lower foundation 5 and the base 3 are all made of concrete pouring; The shape is adapted to the shape of the sound barrier baffle 1 .

[0035] Such as figure 1 , 3 , 4, the two sides of the top opening of the accommodation groove 4 are respectively provided with a vertical guide rail 6, and the vertical guide rail 6 is provided with a vertical groove matching with the edge of ...

Embodiment 2

[0040] Embodiment 2: This embodiment specifically relates to the working method of the inductive lifting sound barrier system in Embodiment 1. This method includes the following steps:

[0041] Such as figure 1 , 10 As shown, the sound barrier plate 1, the base 3 and the lifting mechanism 2 are arranged on both sides of the railway line to form a sound barrier area; and displacement sensors 21 are respectively arranged in front and rear of the sound barrier plate 1, two displacement sensors 21 and the sound barrier The distance between the plate 1 is 200m, and it is specifically fixed at the position between the bottom of the rail and the track plate.

[0042] Such as figure 2 , 10 As shown, when the train enters the sound barrier area, when the wheels of the train pass through the installation position of the first displacement sensor 21, the train causes the rail to generate a large vertical displacement instantaneously. At this time, the first displacement sensor 21 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com