Control method of precipitates and inclusions in twin-roll strip continuous casting of non-oriented silicon steel

A twin-roll thin-strip continuous casting and oriented silicon steel technology is applied in the field of metallurgy to simplify the production process, increase control means, and realize the effect of type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The chemical composition of experimental steel A is shown in Table 1. The molten steel was poured at a temperature of 1620°C, and poured from a tundish preheated to 1200°C into the molten pool composed of rotating steel rolls and side sealing plates of a twin-roll thin strip continuous casting machine. The speed is 50m / min, the strip temperature is 1422±2°C, and the thickness of the cast strip is 2.2-2.5mm; the cast strip enters the secondary cooling section, passes through the slow cooling chamber with a temperature of 800-850°C, and cools slowly for 15 seconds, the end temperature of the slow cooling section 1310~1320°C; after the high-temperature slow cooling, the cast strip immediately enters the third cooling section for rapid cooling, the cooling rate is 70°C / s, and the final cooling temperature is 800°C; the rapidly cooled cast strip is air-cooled to 400°C for coiling.

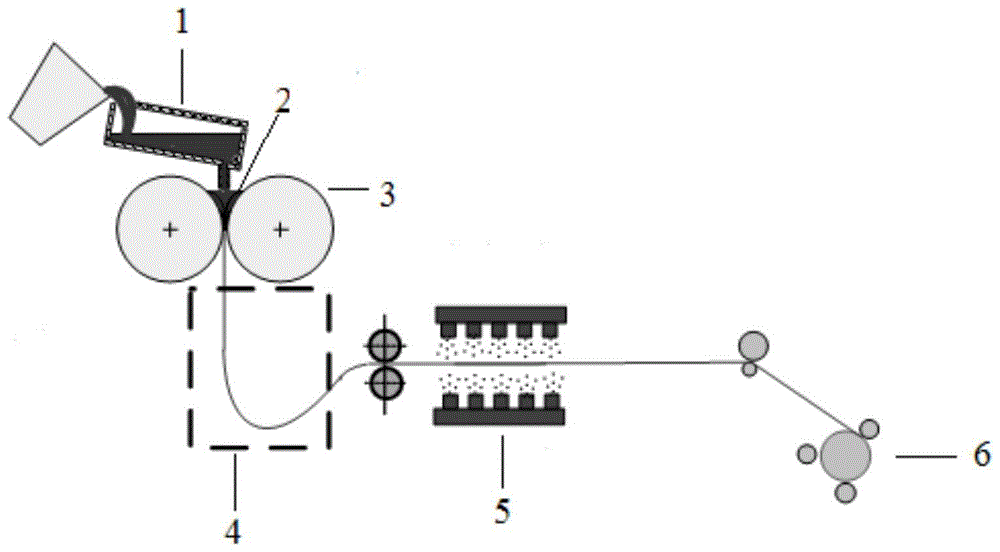

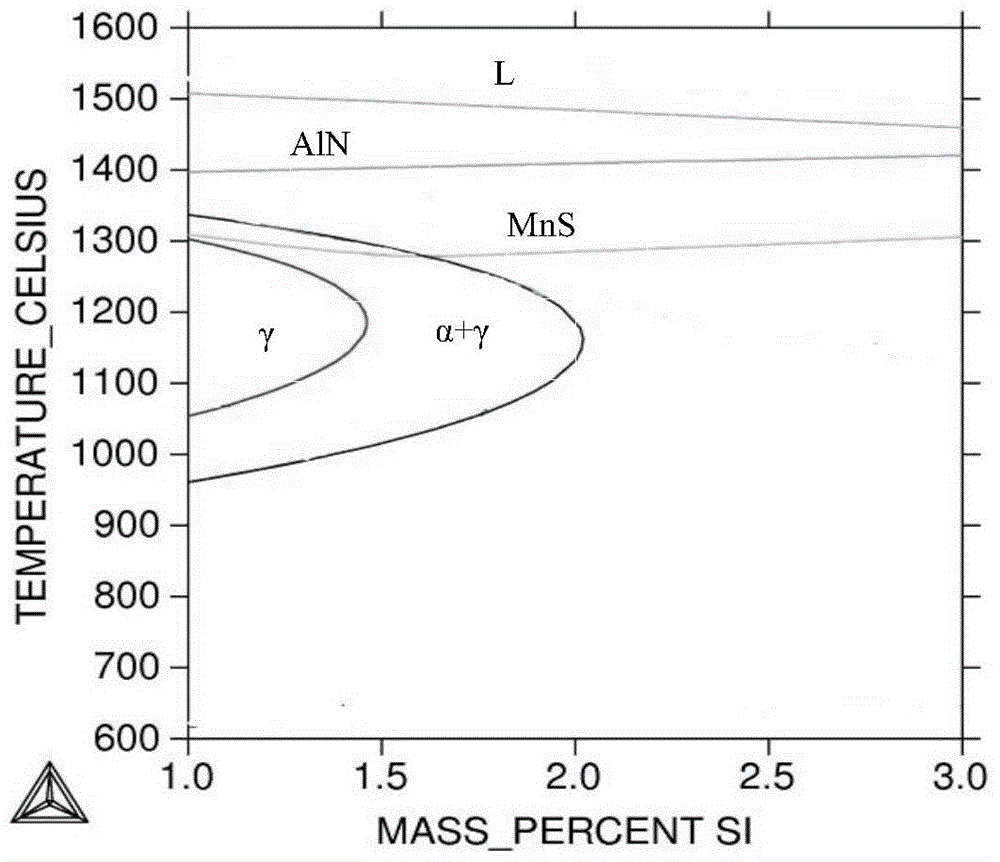

[0033] For the principle of casting and rolling process, see figure 1 , figure 2 The equili...

Embodiment 2

[0037] The chemical composition of experimental steel B is shown in Table 2. The molten steel was poured at a temperature of 1580°C, and poured from a tundish preheated to 1200°C into the molten pool composed of rotating steel rolls and side sealing plates of a twin-roll thin strip continuous casting machine. The speed is 60m / min, the strip temperature is 1380°C, and the thickness of the cast strip is 2.2-2.6mm; the cast strip enters the secondary cooling section and passes through the slow cooling chamber with a temperature of 850-900°C. After slow cooling for 10s, the end temperature of the slow cooling section is 1270- 1290°C; after the high-temperature slow cooling, the cast strip enters the third cooling section for rapid cooling, the cooling rate is 60°C / s, and the final cooling temperature is 780°C; the rapidly cooled cast strip is air-cooled to 500°C for coiling.

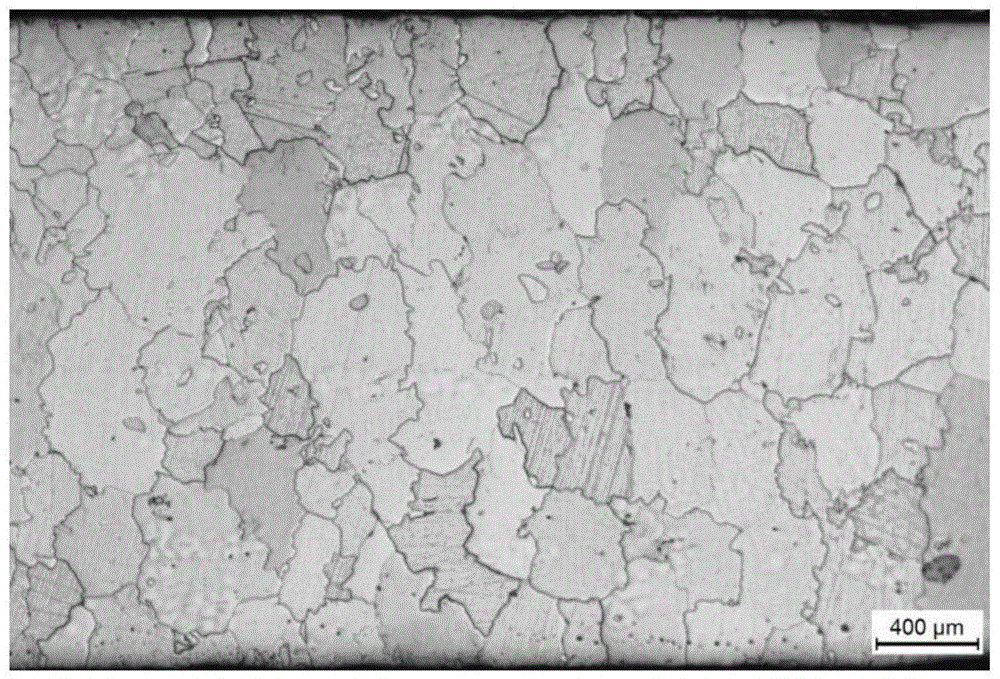

[0038] cast strip structure such as Figure 7As shown, AlN in the cast strip is precipitated alone, reach...

Embodiment 3

[0042] The chemical composition of experimental steel C is shown in Table 3. The pouring temperature is about 1540°C, and the tundish preheated to 1200°C is poured into the molten pool composed of rotating steel rolls and side sealing plates of the twin-roll thin strip continuous casting machine. The speed is 70m / min, the strip temperature is 1385°C, and the thickness of the cast strip is 2.0-2.4mm; the cast strip enters the secondary cooling section, passes through the slow cooling chamber with a temperature of 850-900°C, and after slow cooling for 12s, the end temperature of the slow cooling section is 1270~ 1280°C; after the high-temperature slow cooling, the cast strip enters the third cooling section for rapid cooling, the cooling rate is 50°C / s, and the final cooling temperature is 750°C; the rapidly cooled cast strip is air-cooled to 600°C for coiling.

[0043] cast strip structure such as Figure 9 As shown, AlN in the cast strip is precipitated alone, reaching the lev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com