Catalyst suitable for heavy oil hydrogenation and its preparation and application

A technology for catalysts and oil products, applied in the field of catalysts and their preparation, can solve problems such as inability to build open channels, difficulty in forming, and easy damage to fibrous structures, and achieve improved performance, improved demetallization activity, and improved carbon residue removal activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] B. Preparation of the carrier:

[0031] Mix fibrous pseudo-boehmite and conventional pseudo-boehmite in a certain proportion, add peptizer and water, etc., knead until forming a plastic body, extrude on an extruder, dry and roast for a period of time to obtain a carrier. The roasting temperature is 350-1200°C, the roasting time is 1-12 hours, the optimum roasting temperature is 600-1000°C, and the roasting time is 2-8 hours. The content of fibrous pseudo-boehmite is Al 2 o 3 Calculated as 5-50% of the weight of the carrier, preferably 8-40%;

[0032] C. Catalyst preparation:

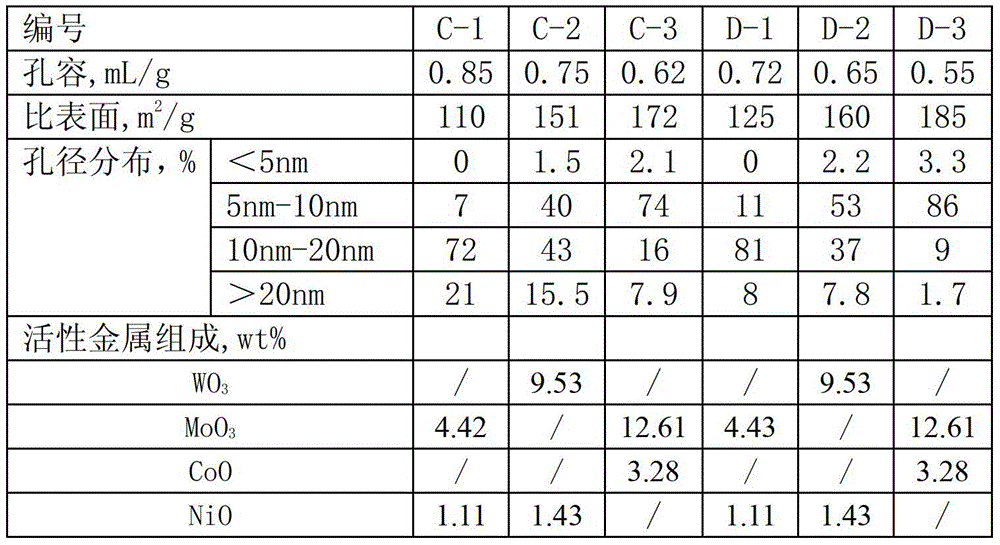

[0033] Using saturated impregnation method, Mo, W, Ni and / or Co are supported on the carrier, by weight of metal oxide, MoO 3 and / or WO 3 It is 1.0-25.0% of the weight of the catalyst, and CoO and / or NiO is 0.6-6.0% of the weight of the catalyst.

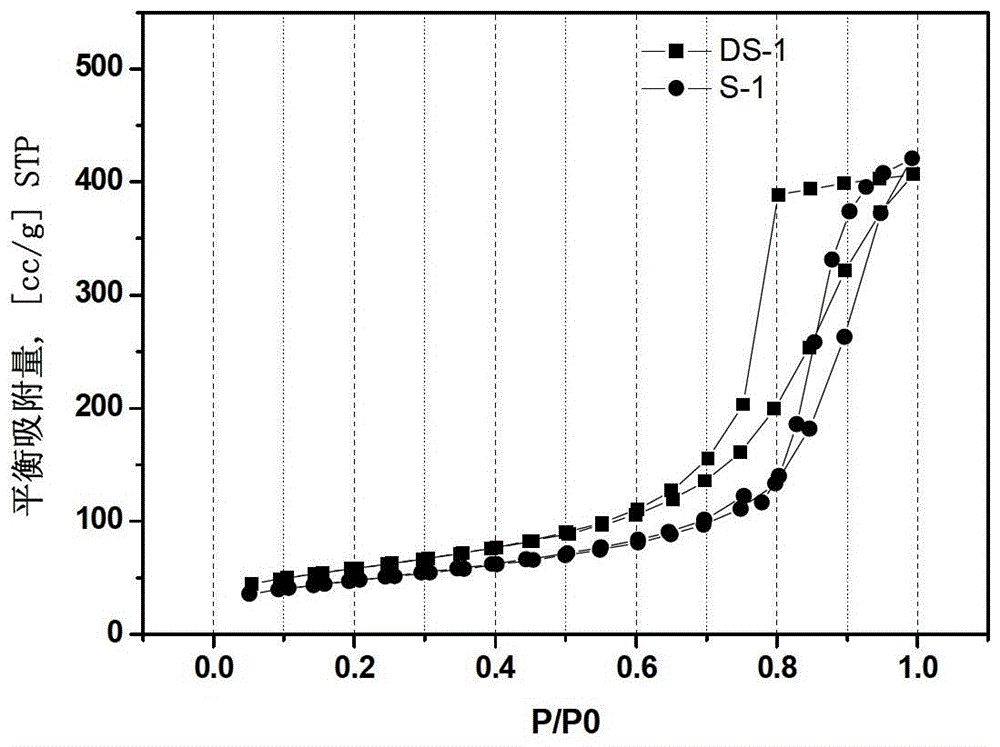

[0034] The specific surface area and pore volume of the product pseudo-boehmite in the examples were measured by nitrogen adsorption method, th...

Embodiment 1

[0036] Pseudoboehmite FP-1 and its preparation method:

[0037] Accurately weigh 295g sodium metaaluminate (produced by German Sigma-aldrich company, Al 2 o 3 Content is 50-56% by weight, Na 2 O content is 40-45%), is dissolved in 1000ml deionized water, is mixed with sodium metaaluminate solution A. Weigh 666.4g of aluminum sulfate octadecahydrate (produced by Shantou Xilong Chemical Factory Co., Ltd., analytically pure), add deionized water to dissolve, and prepare an aluminum sulfate solution with a concentration of 0.4mol / L. Transfer 1800 mL of the prepared aluminum sulfate solution into a flask, and add the prepared sodium metaaluminate solution A dropwise at a speed of 2 ml / min into the three-necked flask at room temperature and under stirring conditions, when the sodium metaaluminate solution After the addition of A was completed, the white suspension was rapidly stirred at room temperature for 2.5 h to obtain a uniform white suspension.

[0038] Pack the obtained u...

Embodiment 2

[0044] Pseudoboehmite FP-2 and its preparation method:

[0045] Accurately weigh 147.5g sodium metaaluminate (produced by German Sigma-aldrich company, Al 2 o 3 Content is 50-56% by weight, Na 2 O content is 40-45%), is dissolved in 1000ml deionized water, is mixed with sodium metaaluminate solution B. Weigh 333.2 g of aluminum sulfate octadecahydrate (produced by Shantou Xilong Chemical Factory Co., Ltd., analytically pure), add deionized water to dissolve, and prepare an aluminum sulfate solution with a concentration of 0.2 mol / L. Transfer 1800 mL of the prepared aluminum sulfate solution into a flask, and add the prepared sodium metaaluminate solution B dropwise at a speed of 2 ml / min into the three-necked flask at room temperature and under stirring conditions, when the sodium metaaluminate solution After the addition of B was completed, the white suspension was rapidly stirred at room temperature for 0.5 h to obtain a uniform white suspension. Pack the obtained unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com