Double-layer temperature-sensitive gel microsphere and preparing method thereof

A technology of temperature-sensitive gel microspheres and temperature-sensitive gels, which is applied in the field of temperature-sensitive gel microspheres, gels for filling and repairing defective tissues, and can solve problems such as molecular chain damage of gels, excessive amount of organic solvents, and degradation of gel quality , to achieve the effect of slow degradation, prolonging the repair time, and simplifying the production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

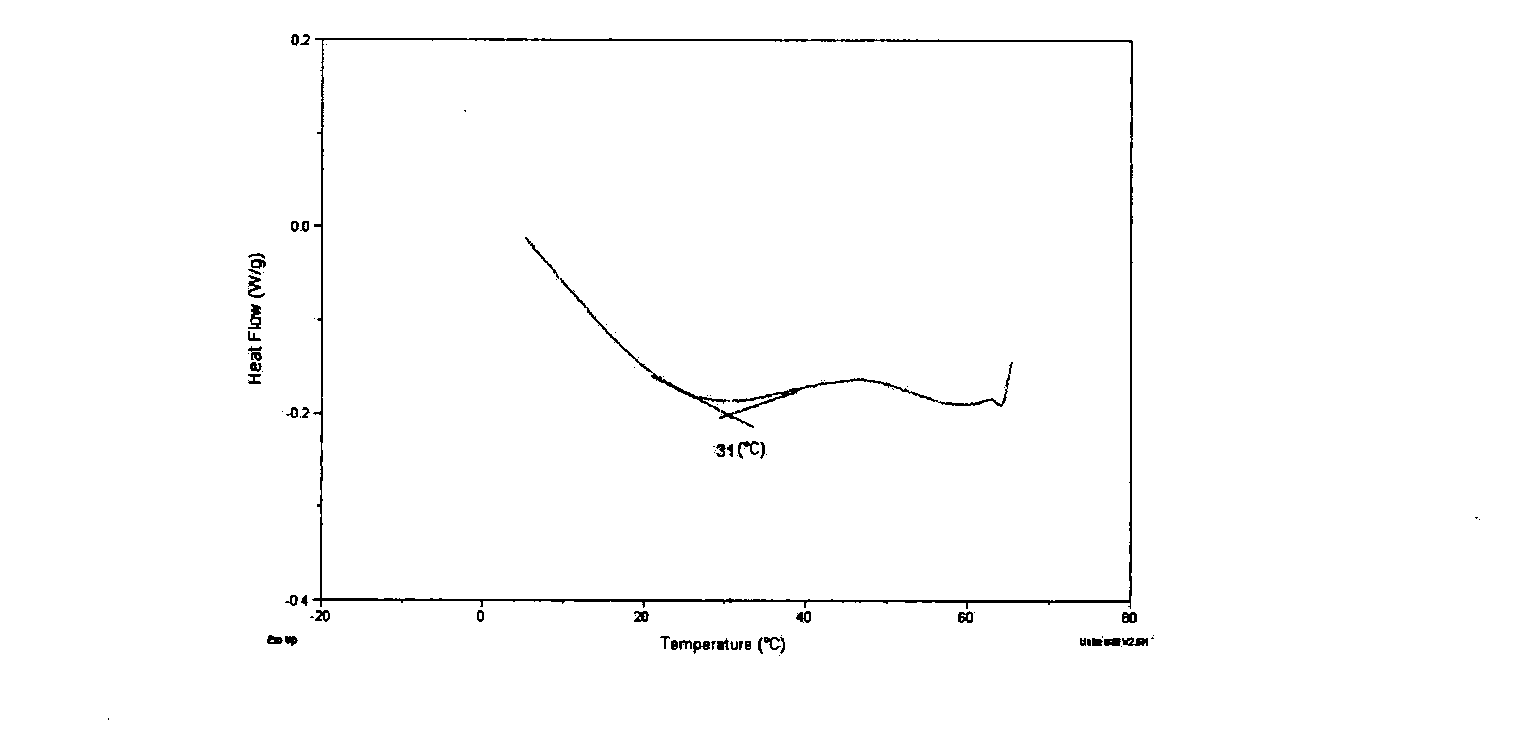

[0035] Prepare 100ml of 2% acetic acid aqueous solution, pour it into a 250ml reactor, add 2g of chitosan and stir at room temperature until the solution becomes transparent, add 2g of NIPAAm and 2mg of KPS into the reactor. Introduce nitrogen and stir at 30°C until the reaction is complete and cool to room temperature, add 50ml of water and stir evenly, add to the attached figure 1 In the syringe (1) shown.

[0036] Prepare a mineral oil / span80 solution with a mass ratio of 80 / 20 and add it to another syringe (2). Place it on a double-rod pump and push the solutions of the two syringes through the common reaction tube (3) at a speed of 10ml / h , and then added dropwise to the 1mg / ml hyaluronic acid dilute solution containing 1% 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC), with a rotating speed of 2000r / Stir at a speed of 1 min until the dropwise addition of the solution is completed, continue to stir for 30 min, and then stand still for 10 min to centrifuge and dia...

Embodiment 2

[0038] Prepare 100ml of 1% hydrochloric acid aqueous solution, pour it into a 250ml reactor, add 1g of chitosan and stir at room temperature until the solution becomes transparent, add 10g of NIPAAm and 2mg of KPS into the reactor. Introduce nitrogen and stir at 40°C until the reaction is complete and cool to room temperature, add 80ml of water and stir evenly, add to the attached figure 1 In the syringe (1) shown.

[0039] Prepare a vegetable oil / span80 solution with a mass ratio of 95 / 5 and add it to another syringe (2). Place it on a double-rod push pump, and push the solutions of the two syringes through the common reaction tube (3) at a speed of 1ml / h. Add it dropwise to the dilute solution of hyaluronic acid with 10mg / ml, stir at a speed of 3000r / min until the addition of the solution is completed, continue to stir for 30min and then stand still for 10min, then centrifuge and dialyze the solution to obtain a double layer Thermosensitive gel microspheres. The thermosen...

Embodiment 3

[0041]Prepare 100ml of 5% boric acid aqueous solution, pour it into a 250ml reaction kettle, add 0.5g chitosan and stir at room temperature until the solution becomes transparent, add 10g of NIPAAm and 2mg of azobisisobutyronitrile into the reaction kettle. Introduce nitrogen and stir at 65°C until the reaction is complete and cool to room temperature, add 50ml of water and stir evenly, add to the attached figure 1 In the syringe (1) shown.

[0042] Prepare a vegetable oil / span80 solution with a mass ratio of 90 / 10 and add it to another syringe (2). Place it on a double-rod push pump, and push the solutions of the two syringes through the common reaction tube (3) at a speed of 5ml / h. Add dropwise to the 2mg / ml hyaluronic acid dilute solution that is equipped with 10% 1-ethyl-3-(3-trimethylaminopropyl) carbodiimide (ETC), and use a rotating speed of 500r / min Stir at a high speed until the dropwise addition of the solution is completed, continue to stir for 30 minutes, then st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com