Free radical resistant tobacco mellowing agent and preparation method and application thereof to threshing, redrying and moisturizing

An alcoholizing agent and free radical technology, which is applied in the field of anti-free radical tobacco leaf alcoholizing agent, can solve the problems of accelerating the natural alcoholization process of tobacco leaves, reducing free radicals, and reducing nicotine, so as to improve the quality of tobacco leaves, reduce free radicals, and reduce nicotine. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of Anti-free Radical Tobacco Alcoholizing Agent A

[0039]Weigh 2.98g α-amylase, 1.26g cellulase, 2.37g acid protease, 0.84g sucrase, 14.54g prune extract (purchased by American Bell Flavors and Fragrances Company, product number is 121.81204, effective antioxidant active ingredient The content is 2g), 16.72g of water and 61.29g of propylene glycol. Firstly, the weighed enzyme is dissolved in water, after being mixed evenly, the prune extract is added, and then mixed evenly in the solvent propylene glycol to prepare 100 g of the anti-free radical tobacco leaf alcoholizing agent A.

Embodiment 2

[0043] Example 2: Preparation of Anti-free Radical Tobacco Alcoholizing Agent C

[0044] Weigh 3.69g α-amylase, 1.57g cellulase, 2.76g acid protease, 0.98g sucrase, 16.54g prune extract (purchased by American Bell Flavors and Fragrances Company, product number is 121.81204, effective antioxidant active ingredient The weight content is 14%), 18.72g water, and 55.74g propylene glycol.

[0045] Firstly, the weighed enzyme is dissolved in water, after being mixed evenly, the prune extract is added, and then mixed evenly in the solvent propylene glycol to prepare 100 g of anti-free radical tobacco leaf alcoholizing agent C.

Embodiment 3

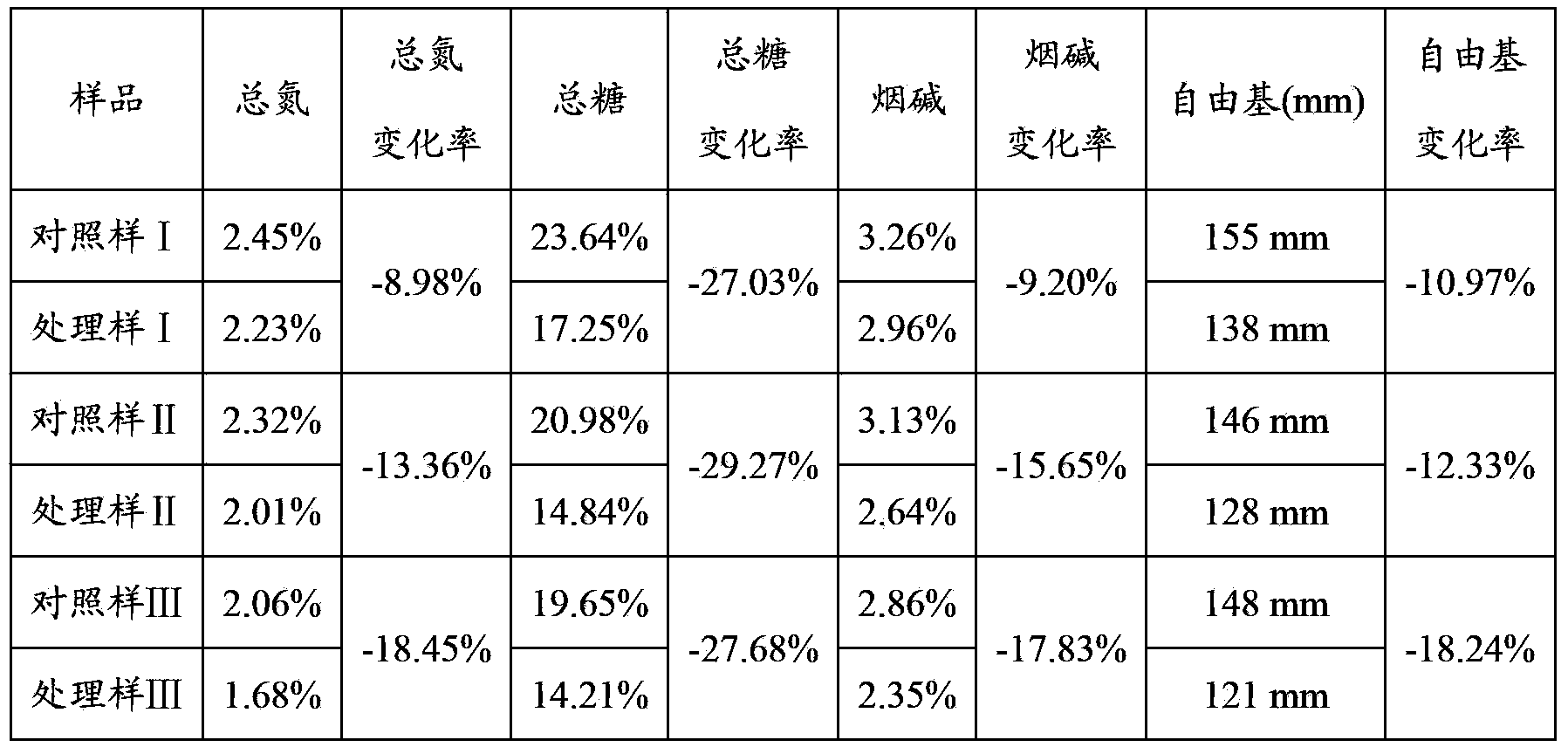

[0049] Embodiment 3: leaf moistening treatment and alcoholization treatment

[0050] 1. Leaf treatment

[0051] Weigh 20kg of C3F grade tobacco leaves from the threshing and redrying line, and divide the tobacco leaves into 2 parts on average. One of them is used as a control sample, which directly carries out the leaf moistening process and the subsequent conventional tobacco processing technology; After dilution, it is evenly sprayed on the surface of the tobacco leaves, and then the leaf moistening process and the subsequent conventional tobacco processing process are carried out.

[0052] The temperature of the leaf moistening process of the control sample and the treated sample was controlled at 55±3°C, and the water distribution ratio of the first-stage leaf moistening and the second-stage leaf moistening was 3:2, so that the moisture content of the tobacco leaves at the outlet of the second-stage moistening leaf was 18.0±3°C. 1% by weight.

[0053] 2. Alcohol treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com