Method for shortening natural aging time of tobacco leaves through ambient temperature and humidity

A technology of aging time and tobacco leaves, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve the problems of long aging time, shortening the natural aging time of tobacco leaves, and high storage costs of tobacco leaves, and achieves the improvement of sensory evaluation and smoking quality, natural aging The effect of shortening the production time and reducing the storage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

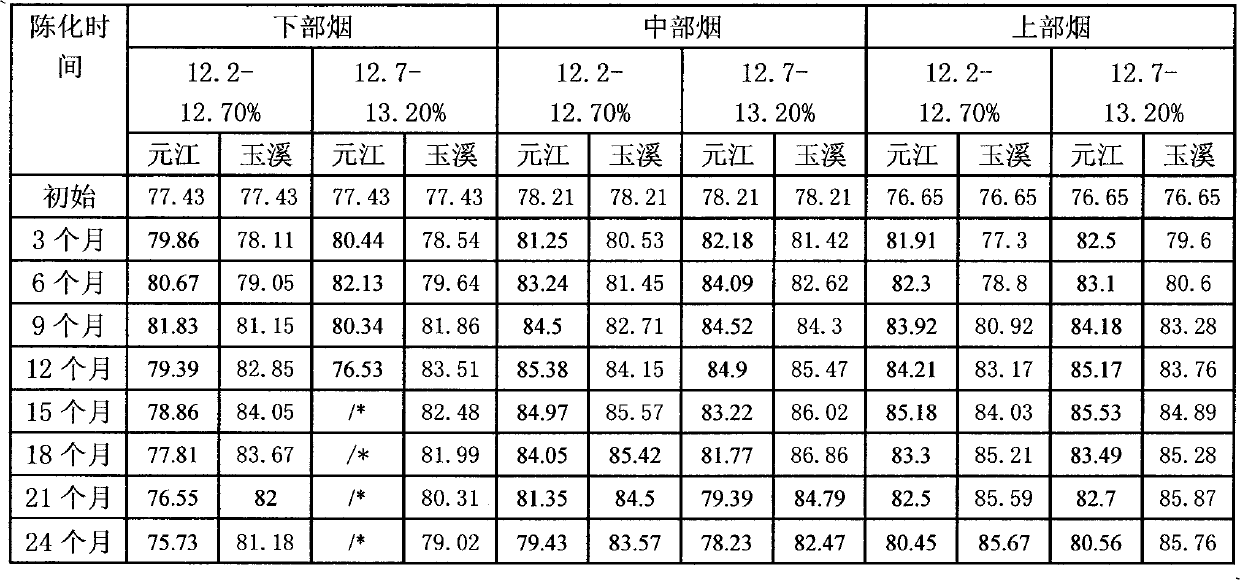

[0018] According to the hot and dry weather conditions in Yuanjiang area, Yunnan, where the annual average temperature is 25-28°C, the annual average relative humidity is 50-60%, and the monthly average relative humidity does not exceed 70%, storage warehouses are set up in Yuanjiang area to transport the upper and middle tobacco leaves. Go to Yuanjiang for natural aging. The indexes of the upper and middle tobacco leaves aged at the existing storage site in Yuxi, Yunnan were used for comparison. Wherein the daily management of the two natural aging processes is prior art.

[0019] 1. Materials and methods

[0020] 1.1 Redecured tobacco leaves

[0021] The Yunnan K-326 variety has grades of upper, middle and lower. The flue-cured tobacco slices of each treatment are packed in cartons, 150Kg / box, and the density is 268.8Kg / cm 3 . There is one wooden stand for every four boxes, and the stacking height is eight layers.

[0022] 1.2 Aging method of recured tobacco leaves

...

Embodiment 2

[0045] Adjust the temperature in the Yuxi aging warehouse in Yunnan to 25-28° C. and the relative humidity to 50-60% according to conventional methods. The obtained results are the same as the natural aging indexes of the upper and middle parts of the Yuanjiang warehouse in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com