Seedbed heating system for planting greenhouse

A heating system and greenhouse technology, applied in the field of greenhouse seedbed heating system, can solve the problems of high content of smoke and carbon dioxide waste gas, uneven heating temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

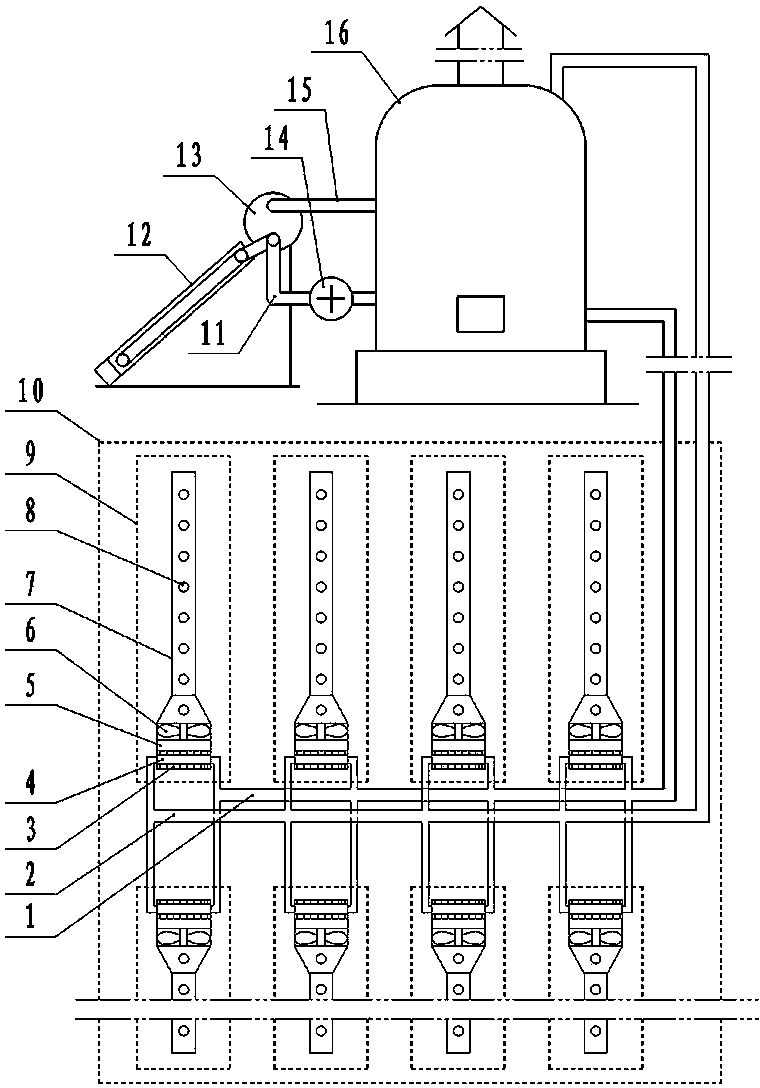

[0006] Example: such as figure 1 As shown, a planting greenhouse seedbed heating system has multiple groups of seedbeds 9 higher than the ground built in the planting greenhouse 10, and is characterized in that: a coil radiator 4 is installed under each seedbed 9 in the greenhouse, Radiator 4 is provided with heat sink 3, and radiator 4 is connected with outlet pipe 2 of hot steam and inlet pipe 1 of cold water. At the front end of radiator 4, air duct 5 is installed, and an exhaust fan is installed at the front end of air duct 5. 6. The front end of the exhaust fan 6 is equipped with an air supply pipe 7, the front end of the air supply pipe 7 is closed, and the upper end is opened with a hot air outlet 8. The outlet pipe 2 of hot steam and the inlet pipe 1 of cold water are connected to the heating boiler 16 outside the greenhouse In the water cavity of heating boiler 16, a group of solar water heaters 12 are installed, and the water inlet pipe 15 and the water outlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com