Piston for an internal combustion engine

A technology for internal combustion engines and pistons, applied to pistons, mechanical equipment, engine components, etc., can solve problems such as damage to piston rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

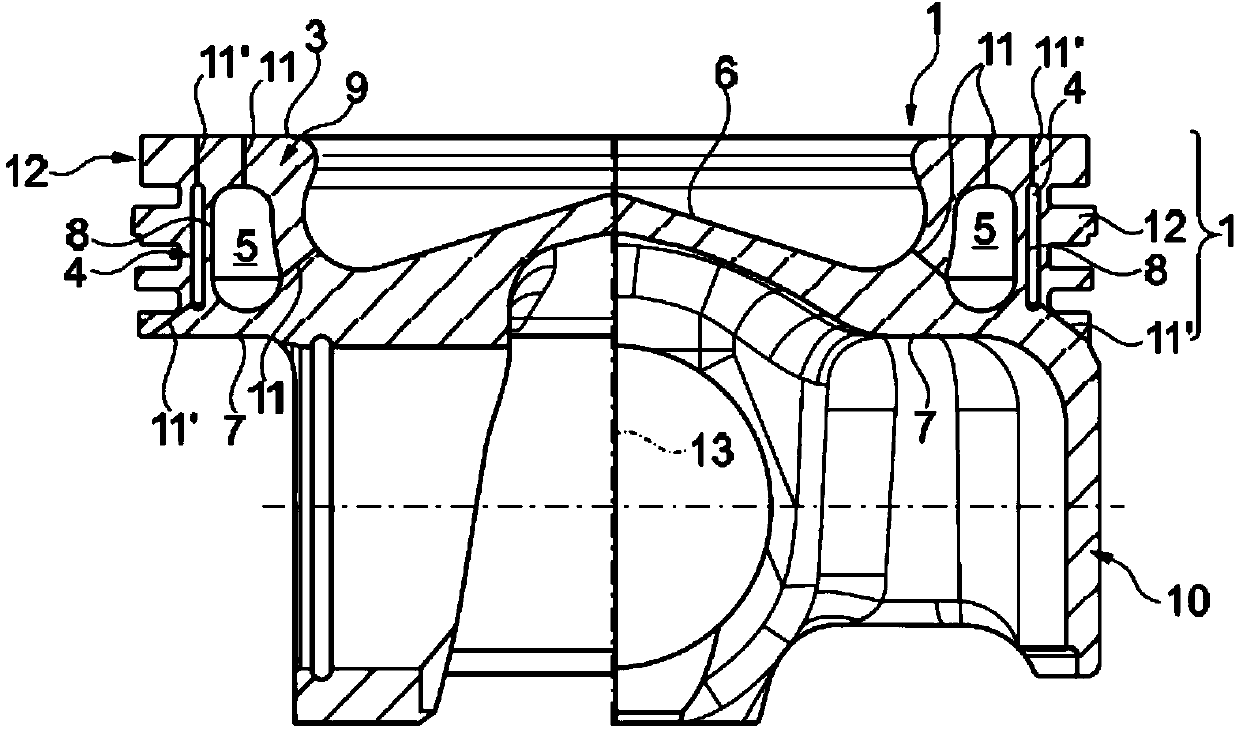

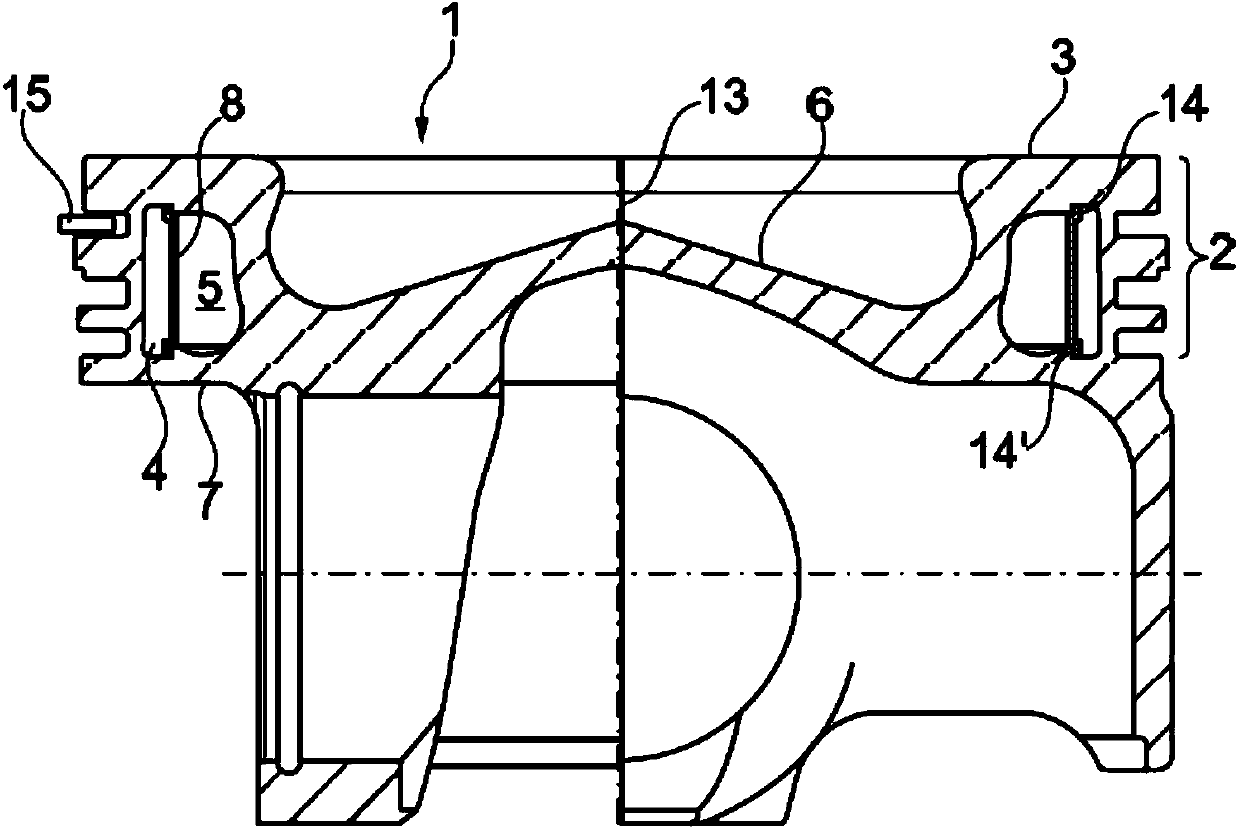

[0025] according to Figures 1 to 4 , according to the invention a piston 1 for an internal combustion engine (not shown) has: a surrounding ring segment 2 in the region of the piston crown 3; a surrounding outer channel 4 in the region of the ring segment 2; and arranged coaxially therewith The inner channel 5. According to the invention, the outer channel 4 is now designed as a thermal insulator, which accordingly insulates the ring segment 2 from the inner channel 5 and the piston bowl 6, which is also designated as the combustion chamber bowl, while the inner channel 5 is designed as a cooling channel and contains The heat transfer medium serves to dissipate heat from the piston crown 3 to the piston underside 7 of the piston 1 .

[0026] The outer channel 4 and the inner channel 5 are here separated from one another by a partition wall 8, wherein the partition wall can be constructed as a separate structural part, in particular as Figures 2 to 4 Illustrated, or wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com