A horizontal thread embedding machine

A wire-embedding machine, horizontal technology, applied in the field of horizontal wire-embedding machines, can solve the problems of vertical wire-embedding machines with complex procedures, cumbersome operation steps, unfavorable production efficiency, etc., to achieve easy clamping, quick replacement, and applicable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

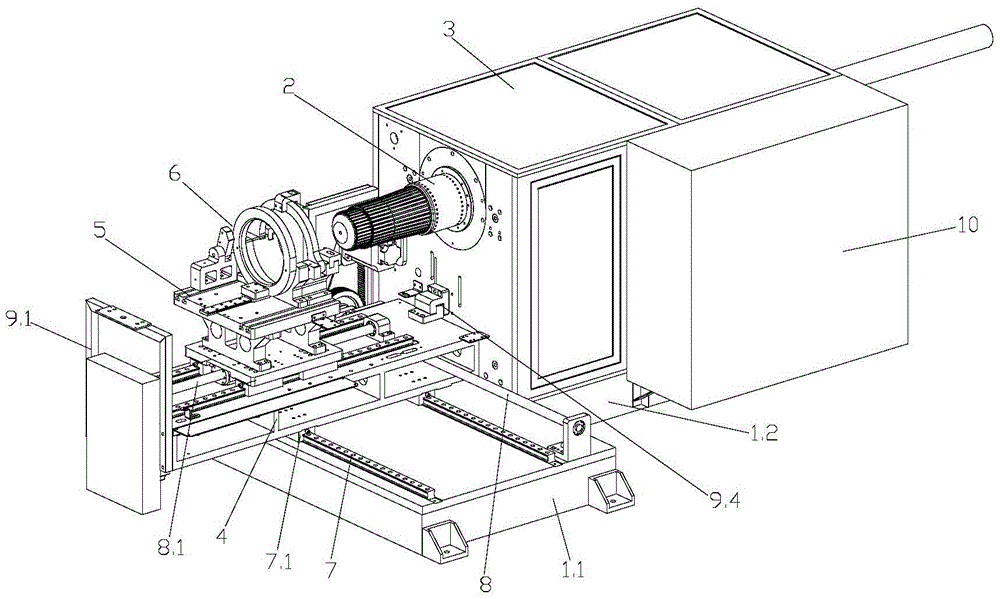

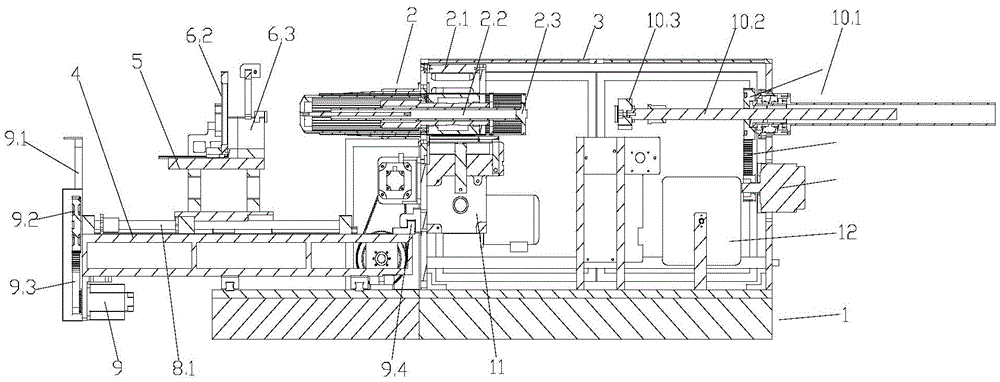

[0017] Such as figure 1 , figure 2A horizontal wire embedding machine shown includes a base 1 composed of a first base 1.1 and a second base 1.2 arranged perpendicular to each other, a wire embedding mold 2, a chassis 3, a propulsion device consisting of a control box 10, and a mold propulsion mechanism 10.1 1. The propelling device and the sliding workbench formed by the propelling device of the carriage, the first base is at the front end of the second base, the cabinet 3 is arranged on the second base 1.2, and the second base 1.2 and the upper surface are provided with a fixing plate, which is convenient for fixing the cabinet, The wire embedding mold 2 is arranged in the middle of the upper part of the front end of the chassis 3 close to the first base 1.2, and is detachably connected with the chassis 3, the control box 10 is arranged on one side of the chassis 3, and the mold pushing mechanism 10.1 is arranged at the rear end of the wire embedding mold 2 Corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com