Transformer respirator

A respirator and transformer technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of affecting the sealing effect, poor sealing, freezing and cracking of oil marks, etc., to achieve the effect of convenient operation and increased height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

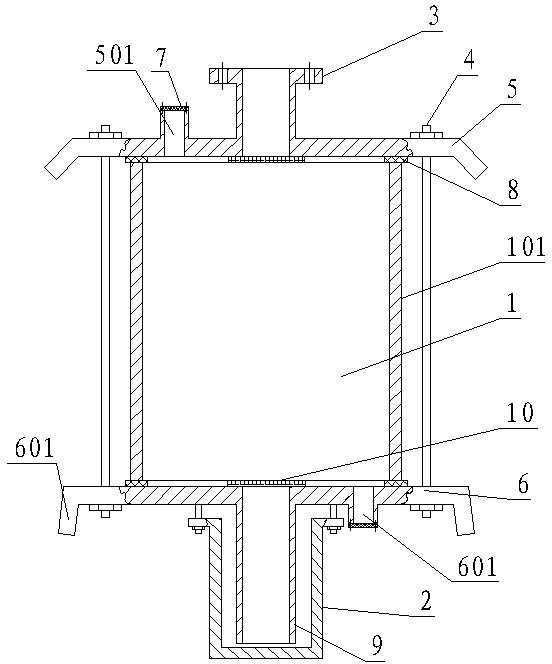

[0013] As shown in the figure, the transformer respirator includes a silica gel tank 1, an oil cup 2 located at the bottom center of the silica gel tank 1, and a flange 3 located at the top center of the silica gel tank 1; the silica gel tank 1 is made of a glass tank body 101 1. The upper and lower end caps 5, 6 connected to the port of the glass tank body 101 by long bolts 4 are formed by a sealing ring 8 arranged between the silica gel tank 1 and the upper and lower end caps; the bottom exhaust pipe 9 of the silica gel tank 1 Insert it into the oil cup 2 and keep a distance of 1cm-2cm from the inner bottom surface of the oil cup 2. On the upper and lower end covers 5 and 6, respectively set a silicone injection port 501 and a silica gel discharge port 601. The sealing cover 10, the long bolt 4 is located outside the silicone tank 1, the outer edge of the lower end cover 6 is provided with a water retaining edge 602 extending downward, and the height of the oil cup 2 is 80mm-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com