High temperature and high pressure true triaxial direct shear fracture seepage coupling test device and its application method

A high-temperature, high-pressure, testing device technology that is applied to measuring devices, using stable shear force to test material strength, using stable tension/pressure to test material strength, etc. Shear rupture testing addresses issues such as high temperature and high osmotic pressure environments to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

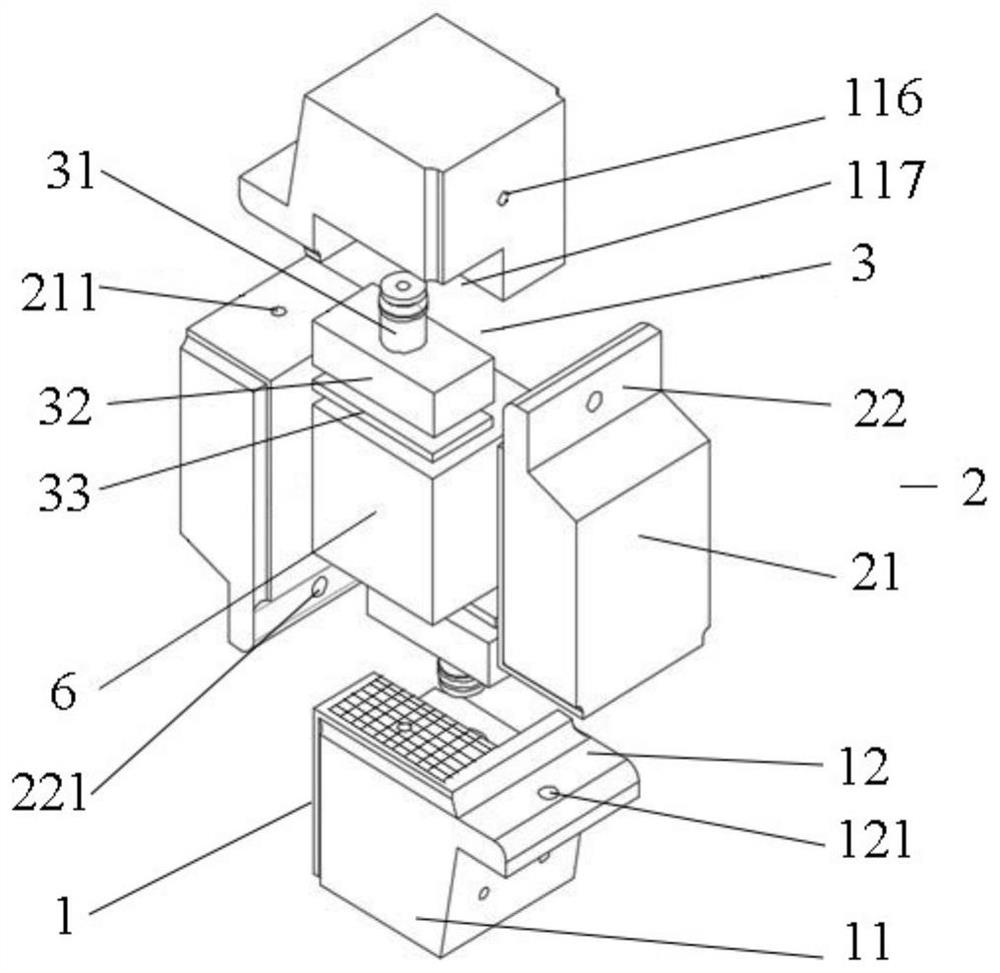

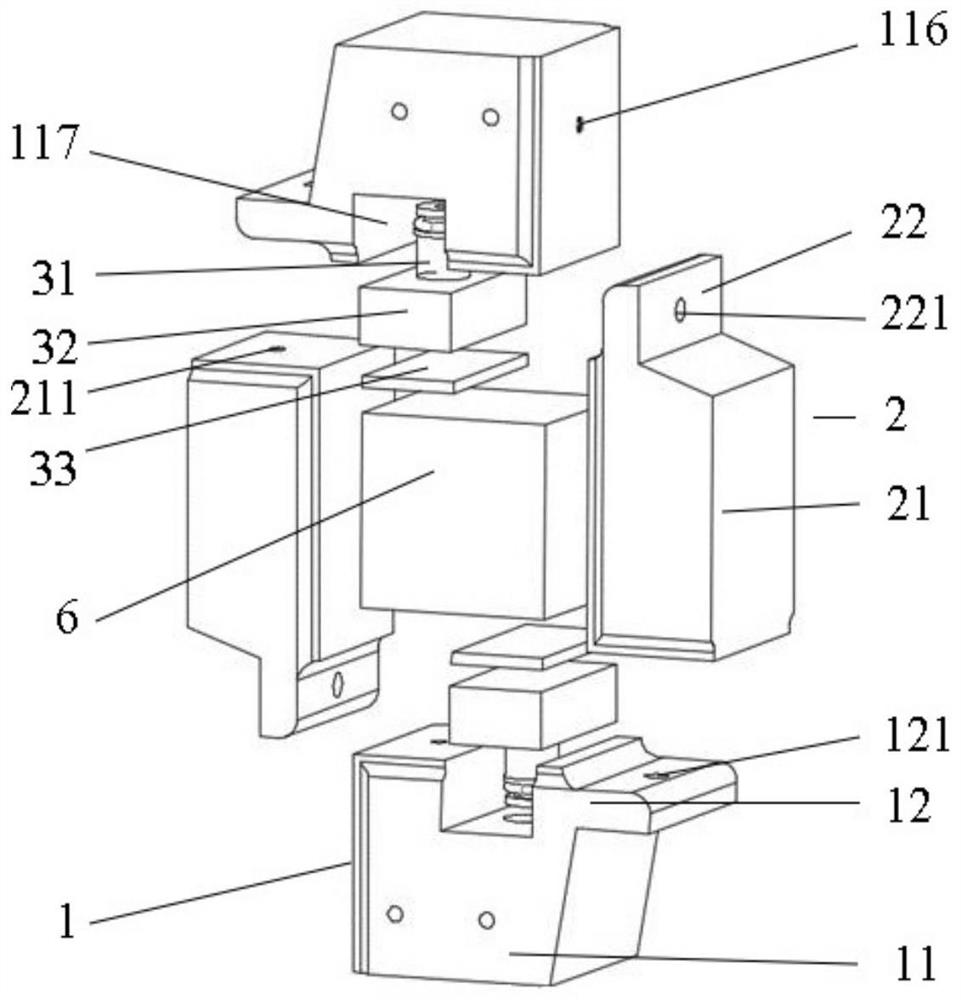

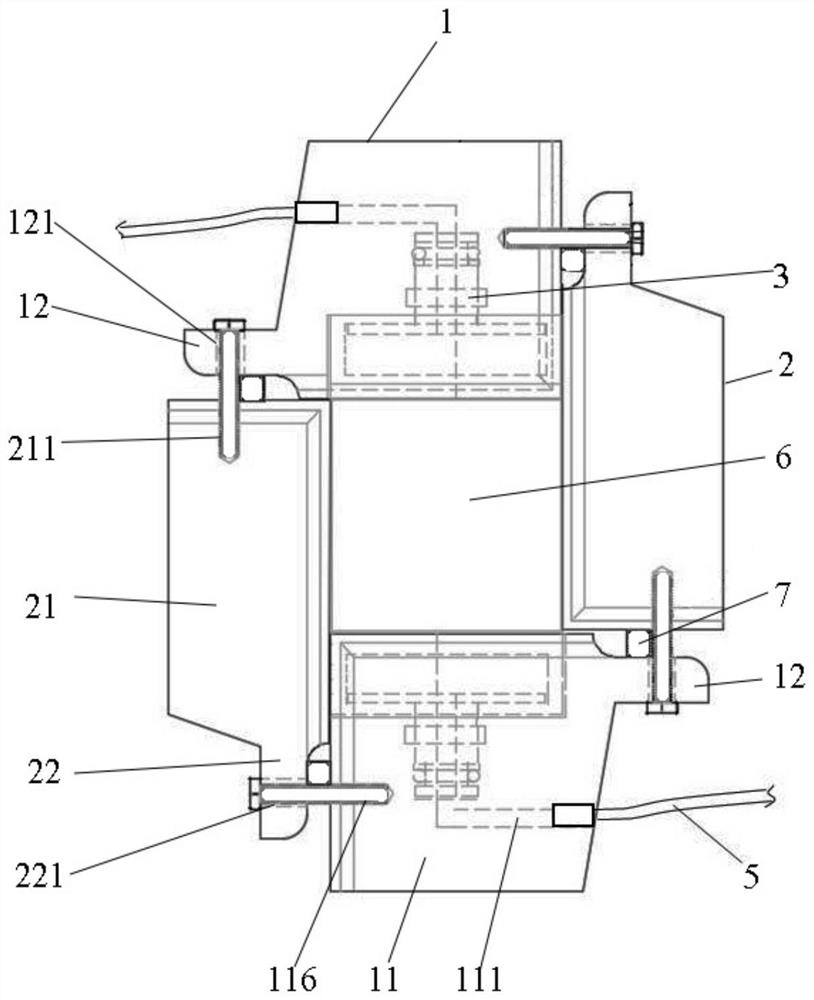

[0096] refer to Figure 1-Figure 3As shown, the embodiment of the present invention proposes a high temperature and high pressure true triaxial direct shear fracture seepage coupling test device for performing unidirectional shear test on rock sample 6, which includes two first indenters 1, two second Two pressure heads 2, two pressure components 3 and a pipetting component 4. The two first indenters 1 and the two pressure assemblies 3 are respectively arranged on the upper and lower sides of the rock sample 6 in a symmetrical manner with respect to the center of the rock sample 6 . Two second indenters 2 are arranged on the left and right sides of the rock sample 6 in a symmetrical manner with respect to the center of the rock sample 6 . The pipetting assembly 4 is used to inject hydraulic oil into the first pressure head 1 and the pressure assembly 3 .

[0097] After the first indenter 1, the second indenter 2, the pressure assembly 3 and the rock sample 6 are assembled, t...

Embodiment 2

[0155] refer to Figure 12 and Figure 13 As shown, the embodiment of the present invention proposes a high temperature and high pressure true triaxial direct shear fracture seepage coupling test device for bidirectional shear test on rock sample 6, including two first indenters 1, two second indenters Head 2 and four pressure components 3 . Among them, the structure of the first pressure head 1 and the second pressure head 2 are the same, the structures of the four pressure components 3 are the same, and the assembly method between the first pressure head 1 and the corresponding pressure components 3 is the same as that of the second pressure head 2 and the The assembly methods of the corresponding pressure components 3 are consistent. The two first indenters 1 and the two pressure assemblies 3 are respectively arranged on the upper and lower sides of the rock sample 6 in a manner symmetrical to the center of the rock sample 6, and the two second indenters 2 and the two press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com