High-precision tool locking device of five-axis machining center and tool changing method

A locking device and high-precision technology, applied in the field of CNC machine tools, can solve problems such as affecting machining accuracy and spindle structure wear, and achieve the effect of preventing machining accuracy from falling and cutting tools from falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

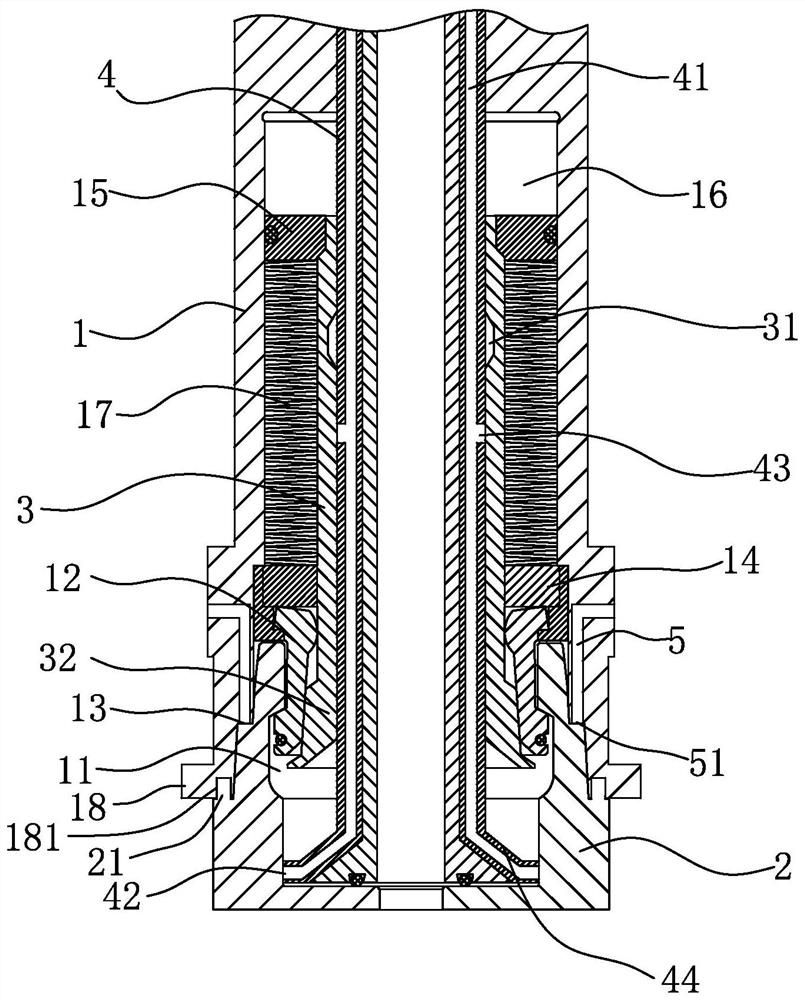

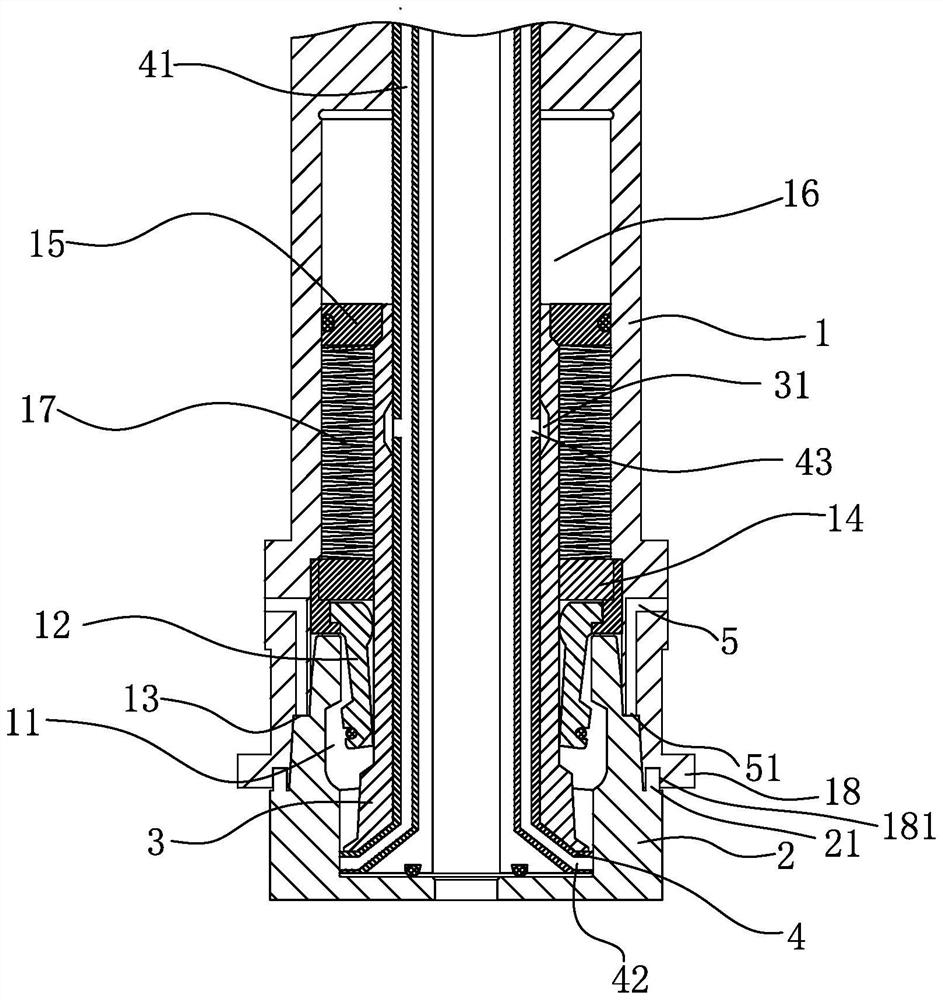

[0042] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings:

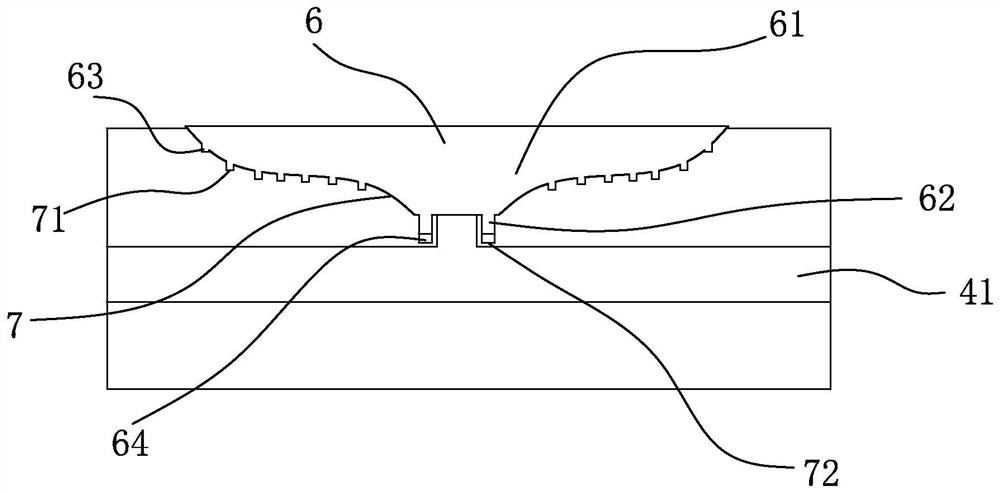

[0043] refer to figure 1 , figure 2 , Figure 7 , the end face of the main shaft 1 is provided with a snap ring 18 that conflicts with the tool 2, the snap ring 18 is provided with a slot 181, the tool 2 is provided with a block 21, and when the tool 2 is inserted into the main shaft 1, the block 21 is inserted into the slot 181 to ensure that the main shaft 1 The accuracy when inserting, reducing the wear of the tool 2 and the internal structure of the spindle 1. Simultaneously, a vibration-damping pad 182 is arranged between adjacent draw-in slots 181, which can reduce the impact of vibration on the mating of the draw-in blocks 21 and draw-in slots 181, reduce wear of the draw-in blocks 21 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com