Method for measuring content of sulfur in coal by utilizing energy chromatic dispersion X-ray fluorescence analysis

A technology of energy dispersion and fluorescence analysis, which is applied in the field of analysis and detection, can solve the problem of low sensitivity of sulfur element, and achieve the effect of quantitative analysis, fast measurement and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

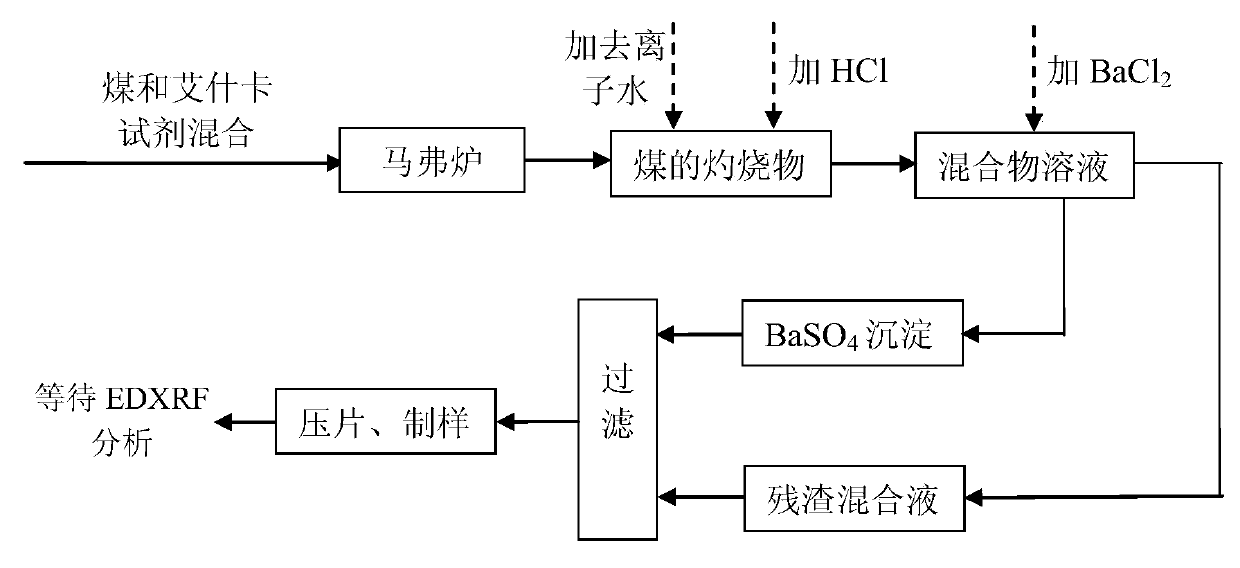

[0013] The experiment refers to the Ashka method in the national standard GB / T 214-2007 "Determination of total sulfur in coal" to pretreat the coal sample. The specific implementation process is as follows figure 1 Shown:

[0014] ①Weigh 1g of dry coal sample with a particle size less than 0.2mm and 2g of Ashka reagent (mixed with magnesium oxide and anhydrous sodium carbonate at a mass ratio of 2:1) in a 30ml porcelain dry pot and mix evenly, then use 1g of Ashka The reagent is covered on the coal sample;

[0015] ② Move the dry pot containing the coal sample into a well-ventilated muffle furnace, and gradually heat it from room temperature to 840°C in 1.5 hours. Must be kept at this temperature for 2h. Using the temperature programming control device of the muffle furnace, the temperature of the muffle furnace was slowly raised from room temperature to 840° C. in the course of 1.5 h. The sample is burned in the muffle furnace, and its reaction formula mainly includes:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com