A new fiber optic hydrophone probe package structure and fiber optic hydrophone array

A technology of optical fiber hydrophone and packaging structure, which is applied in the direction of instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., and can solve the problem of poor resistance to deep water pressure of PU rubber tubes and light wax oil, reduced detection sensitivity, and occupancy Large site space and other issues, to achieve the effect of flexible and controllable assembly method, stable and reliable connection strength, and small occupied site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

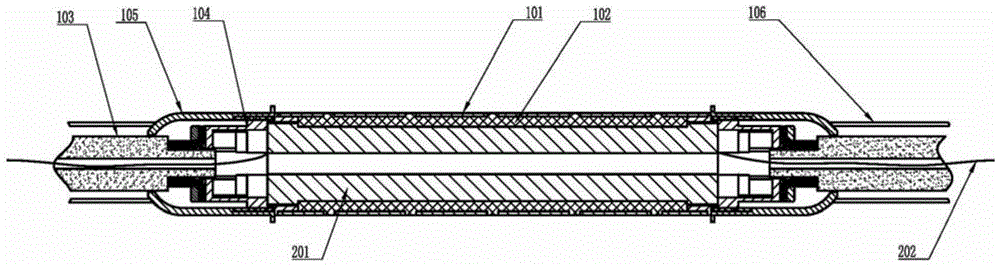

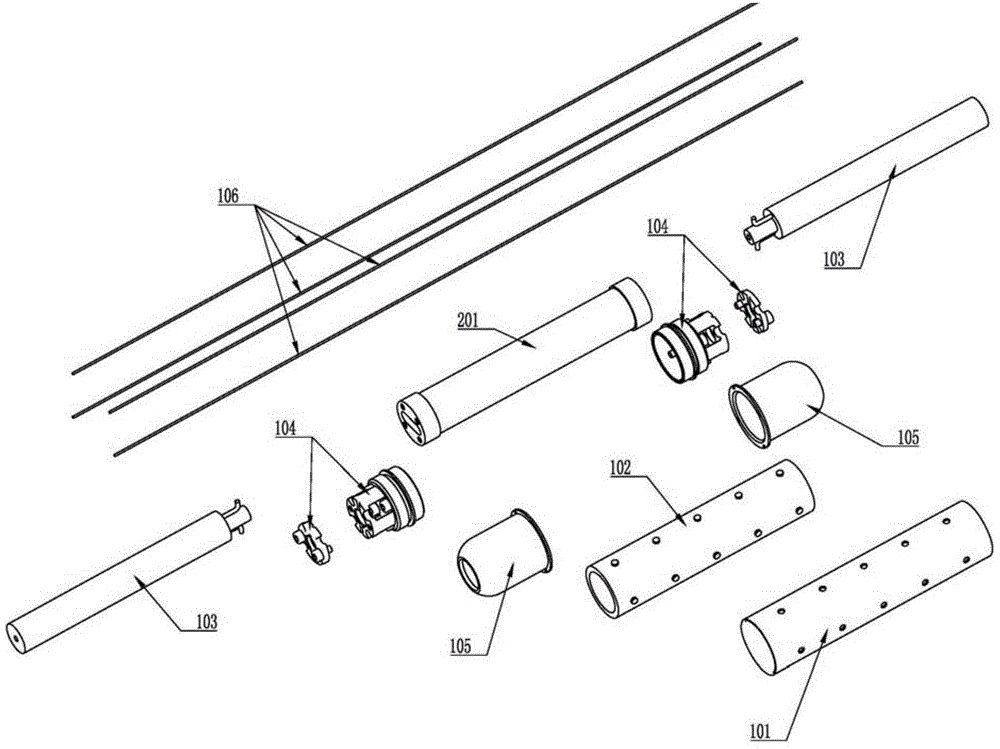

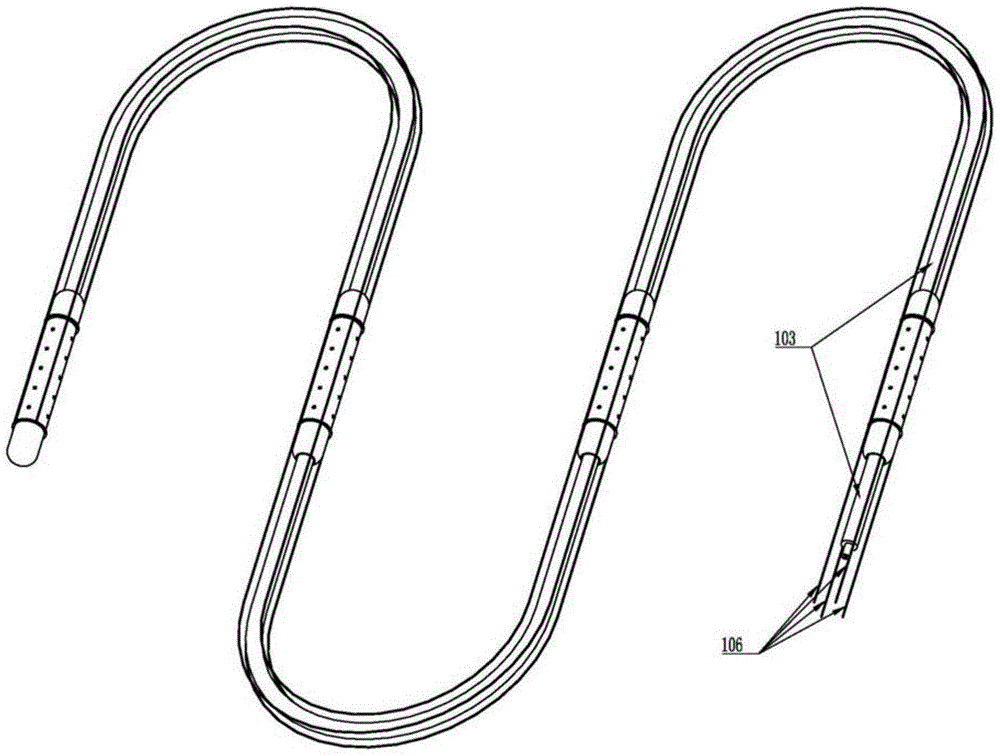

[0027] Such as figure 1 , figure 2 As shown, the present invention provides a novel optical fiber hydrophone probe packaging structure, including: a housing 101, a polyurea composite material 102, an armored optical cable 103, a pressure plate joint 104, a transition sleeve 105, a Kevlar cord 106, and an acoustic sensor 201 and fiber 202;

[0028] The acoustic sensor 201 is hollow tubular and is an interference type fiber optic hydrophone. Its two ends are respectively fixedly connected to the armored optical cable 103 through the pressure plate joint 104, and the steel wire at the end of the armored optical cable 103 is compressed inside the pressure plate joint 104, and the connection method has a certain mechanical strength. The outside of the pressure plate joint 104 is covered with a transition sleeve 105, which is designed in a streamlined shape to reduce the resistance when dragging in water. Both ends of the transition sleeve 105 are coated with polyurea composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com