Immersed film type heat exchanger

A heat exchanger and thin-film technology, which is applied in the field of immersion thin-film heat exchangers, can solve the problems of high requirements, dry spot production and installation, and high requirements for liquid distribution, so as to achieve good film-forming performance and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

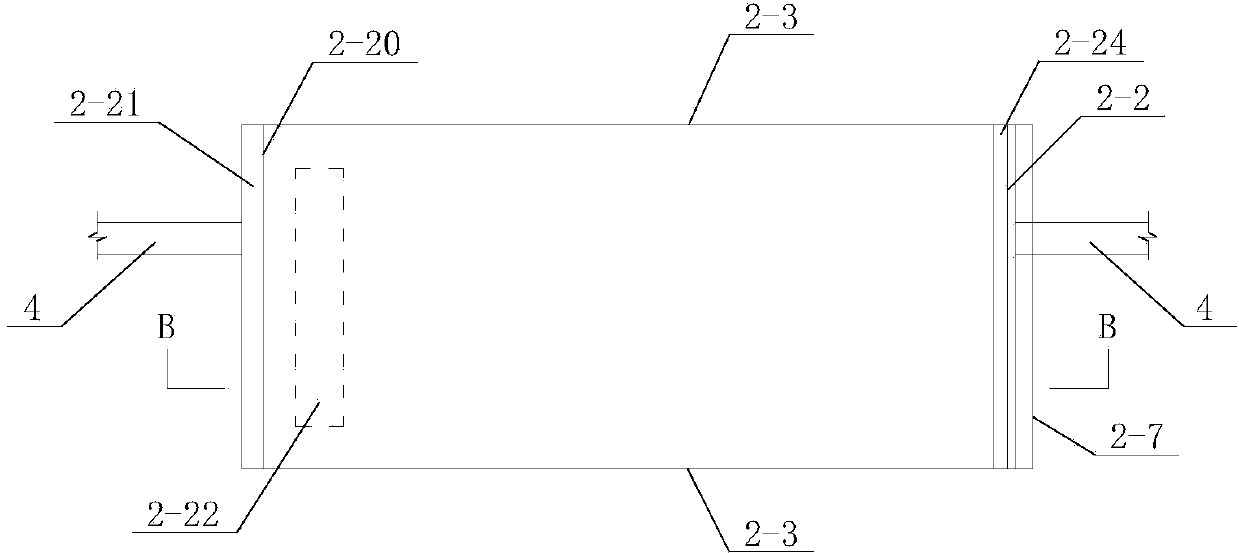

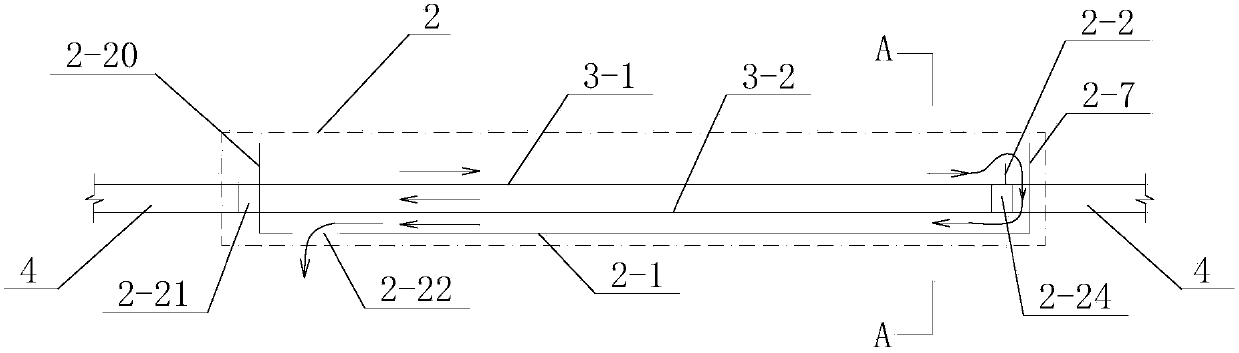

[0014] Specific implementation mode one: combine Figures 1 to 4 Describe this embodiment, this embodiment includes a housing 1, in which a plurality of heat exchange units 2 are arranged sequentially from top to bottom, and two adjacent heat exchange units 2 are arranged in the same direction, and the side wall or top of the housing 1 is provided with A steam port 1-1 and a first heat exchange medium inlet pipeline 1-5, the bottom of the shell 1 is provided with a first heat exchange medium outlet 1-2, and the side wall of the shell 1 is provided with a second heat exchange medium inlet pipeline 1-3 and the second heat exchange medium outlet pipeline 1-4,

[0015] Each heat exchange unit 2 includes a support plate 2-1, an upper heat exchange plate 3-1, a lower heat exchange plate 3-2, a first baffle plate 2-2, a third baffle plate 2-7, and a fourth baffle plate 2 -20, the first header box 2-21, the second header box 2-24 and two second baffles 2-3, the supporting plate 2-1, ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 , 5 , 6 and 7 illustrate the present embodiment, the supporting plate 2-1 of the present embodiment has several spray holes 2-6. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 and 8 This embodiment will be described. The upper heat exchange plate 3-1 and the lower heat exchange plate 3-2 of this embodiment are corrugated plates. Other implementations are the same as the first or second implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com