Servomotor-speed reduction integrated mechanism

A servo motor and gearbox technology, applied in mechanical equipment, transmission parts, shafts, etc., can solve the problems of small locking screws, easy sliding teeth, and the two ends of the keyway connection are not concentric, so as to reduce space, simplify installation, Reduce the effect of mating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

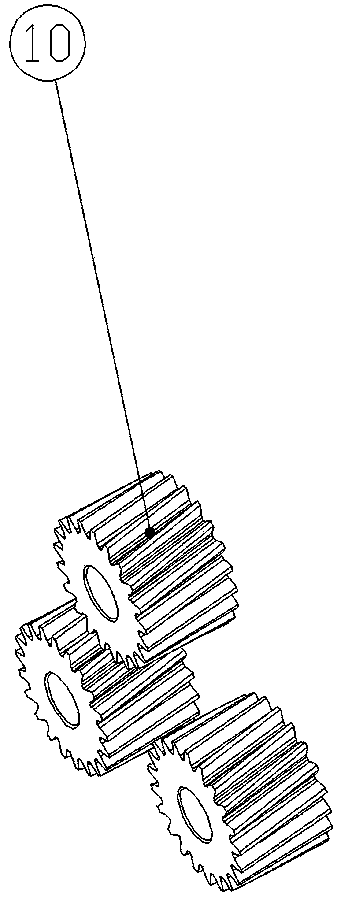

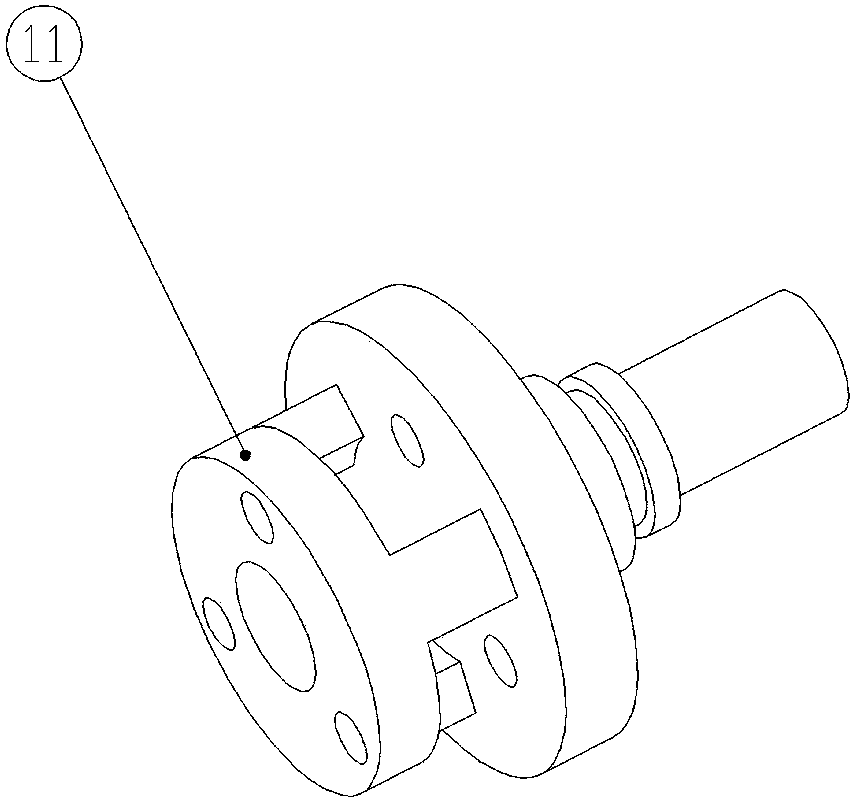

[0019] refer to Figure 1-Figure 4 Shown, a kind of servomotor deceleration integrated mechanism, comprises servomotor output shaft 4, planetary gear 10, planetary wheel disc 11, gearbox upper cover 5 and gearbox lower cover 14, one end of described servomotor output shaft 4 is set There is a shaft-end gear, and the shaft-end gear meshes with a planetary gear 10. A through hole is provided in the middle of the planetary gear 10. The planetary gear 10 is matched with the planetary gear fixing pin 9, and a planetary gear 10 and a planetary gear are fixed Interference fit is adopted between the pins 9, and the fixed pin 9 of the planetary wheel is fixed on the planetary wheel 11 through the through hole, and the other end of the planetary wheel 11 is the output shaft, and the center of the planetary wheel 11 and the output shaft The lines are consistent, the output shaft is provided with an output shaft bearing 13, and the lower cover 14 of the gearbox is provided with a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com