Radial roller screw and variable-speed transmission thereof

A variable-speed transmission and screw technology, which is applied in transmission elements, transmission devices, vehicle gearboxes, etc., can solve the problems of affecting cutting processing and accuracy, large fluctuation of output speed, and increase in heating temperature, etc., which is conducive to cutting processing, output The effect of stable rotation speed and reduction of heat generation and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

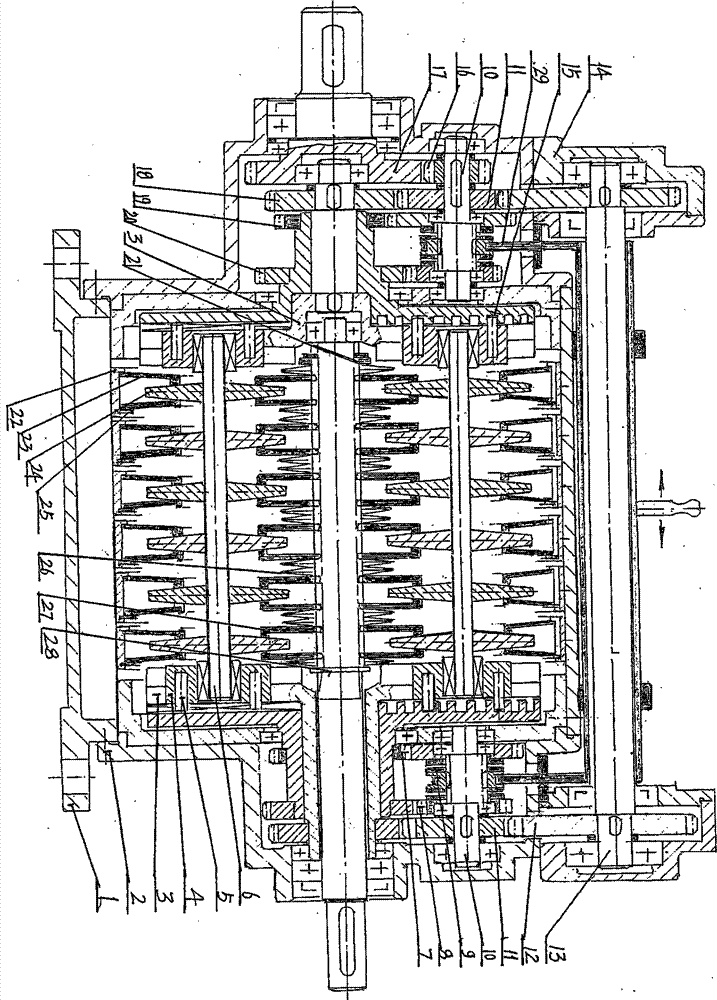

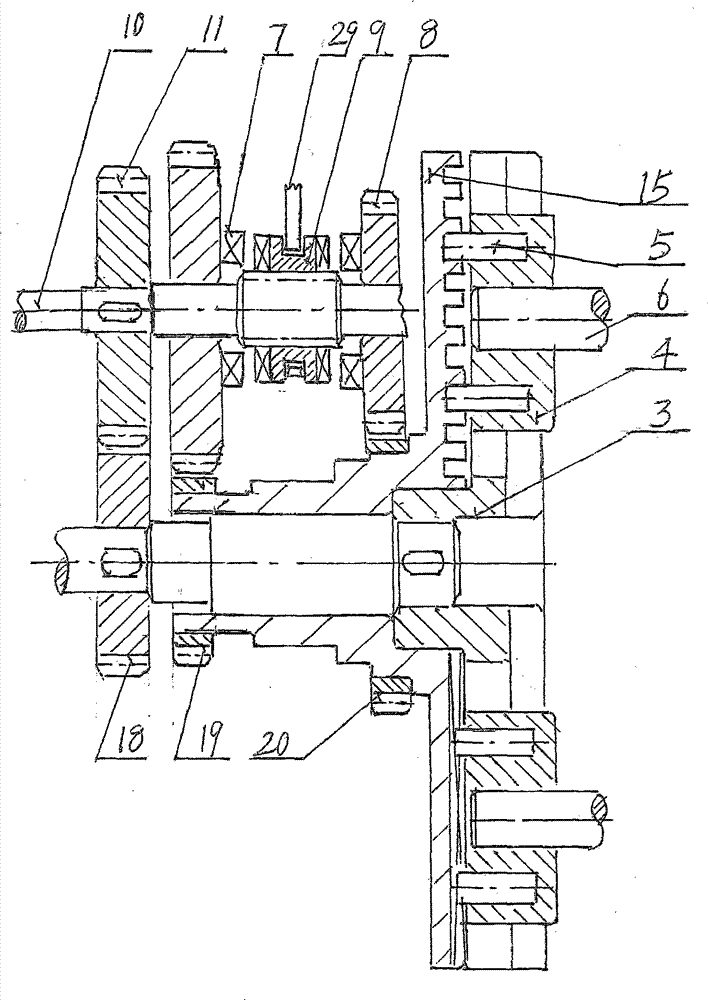

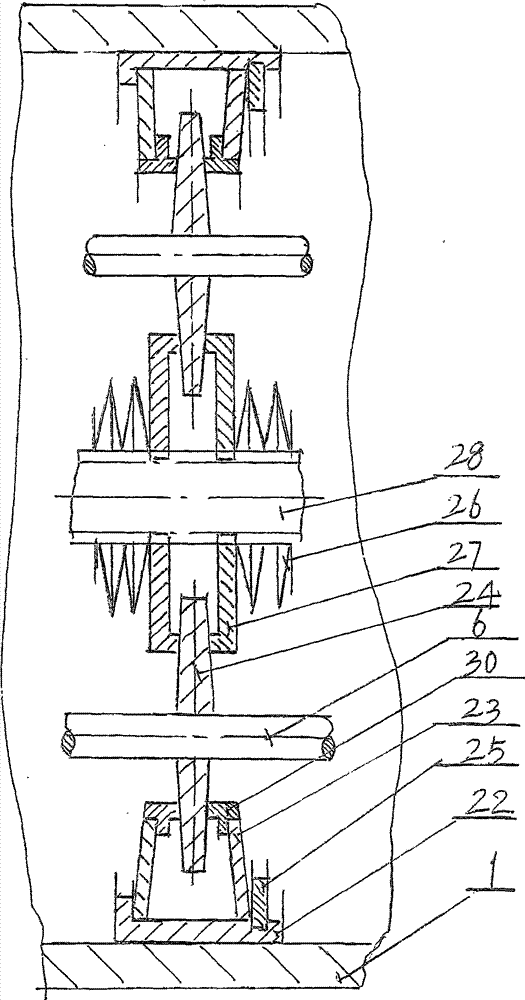

[0041] The best way to implement the present invention is described in detail according to the accompanying drawings, several pairs of driving wheels (27) are connected at the input spline shaft (28), and the inner disc spring (26) is arranged on the outside to clamp the planetary gear (24), and the outer disc Spring (23) and outer pressure ring (30) also press the radial periphery of planetary wheel (24), when input spline shaft (28) drive driving wheel (27) and planetary wheel (24), because outer pressure ring (30) is clamped by the deformed elastic force of outer dish spring (23), has produced the revolution of planetary gear (24), and each planetary gear (24) promotes careful axle (6), slide block (4) rotating disk (3) ) and crankshaft (15) output torque.

[0042] After the control lever (29) and the intermediate clutch (9) are combined with the grooved gear ① or gear ②, through the transmission of the corresponding chain gear ① or chain gear ②, because the number of teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com