Constant proportional variable speed collective transmission device

A constant-proportion speed change and transmission technology, which is applied to transmissions, transmission parts, belts/chains/gears, etc., can solve problems such as increased kinetic energy consumption, heat generation and wear, and reduced service life, and achieves easy and labor-saving speed regulation. The effect of axial dimension reduction and reduction in pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

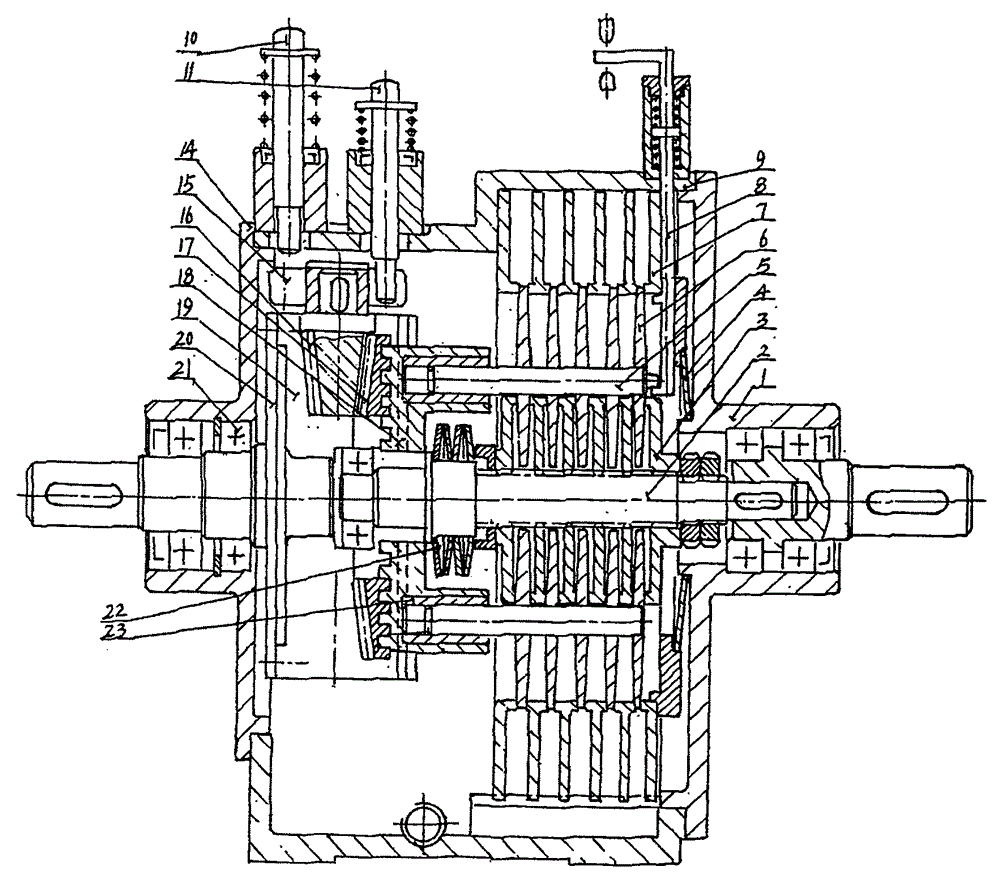

[0031] figure 1 In the process, the rotating shaft 2 inputs power and transmits it to each driving wheel 3, each driving wheel 3 is pressed by the disc spring group 22, and each planetary wheel 6 is pressed, so that each planetary wheel 6 rotates, and the planetary wheel 6 is pressed by the outside The circle 7 is compressed, and without rotation, the planetary wheel 6 pushes the mandrel 5 to make a circular revolution with the inner hole. Because the mandrel 5 is coupled in the sleeve 23 of the slide block 18, it pushes the slide block 18 and its rotating disk 19 to perform output operation while rotating. The slider 18 and the bevel gear 17 are driven by a spiral pair. When the pins 10 and 11 move the external gear 15, the small bevel gear 16 meshes with the bevel gear 17 to make it rotate, and the slider 18 drives the mandrel 5 and the planets through the screw transmission. The wheel 6 is radially displaced to achieve stepless speed change.

[0032] The output torques of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com