Selective Production String and Working Method of Multi-Stage Fracturing Horizontal Well Completion with Casing

A working method, selective technology, applied in casing, production fluid, wellbore/well components, etc., can solve the problems of test failure, self-sealing packer unable to run, drag and trip out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

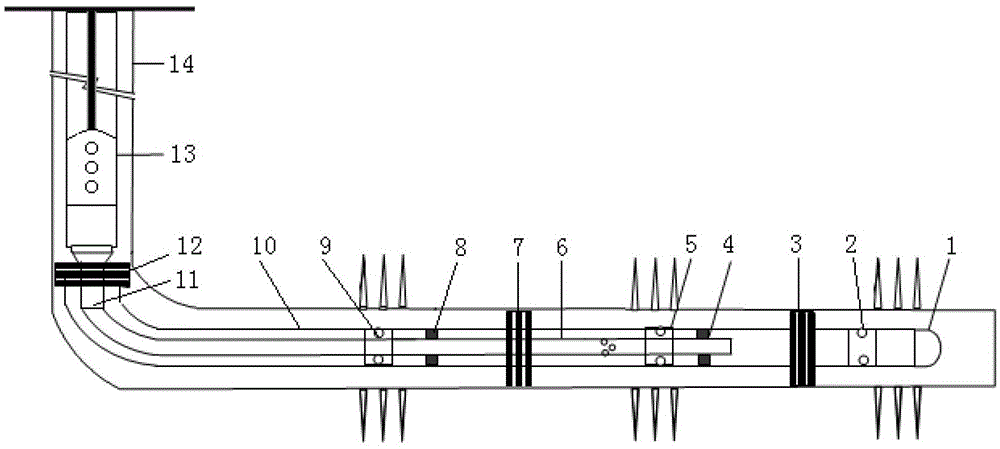

[0012] refer to figure 1 Embodiments of the present invention are further described:

[0013] The outside of the tubing string 10 is connected from top to bottom with the Y445 hand-off packer 12 of the separating casing 14, the upper packer 7 of the Y441 intubation and the lower packer 3 of the Y441 intubation; From top to bottom, connect the deep well pump 13, the sealing cannula 11 connected to the Y445 hand-off packer 12, the upper constant pressure valve 9 and the upper sealing cylinder 8 of the upper section of the opposite casing 14, and the middle section of the opposite casing 14. The middle constant pressure valve 5 and the lower sealing cylinder 4, the lower constant pressure valve 2 and the guide plug 1 of the lower section of the casing 14; Constant pressure valve and sealing cylinder.

[0014] The working method of this pipe string is as follows:

[0015] 1) Run the separation pipe string: first, install and connect the guide plug 1, each packer, each constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com