Gray solar reflective cooling coating and preparation method thereof

A technology of solar heating and coatings, applied in the direction of reflection/signal coatings, multi-color effect coatings, coatings, etc., can solve the problems of short outdoor service life, reduced living comfort, poor anti-aging performance, etc., and achieve excellent light stability and weather resistance, good near-infrared reflection performance, and long outdoor service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

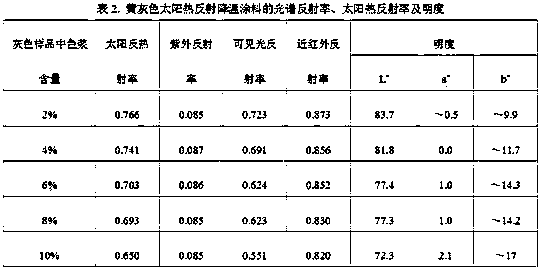

[0053] A kind of gray solar heat reflection cooling paint is characterized in that: its component and weight ratio are:

[0054] 80 parts of white paint color paste;

[0055] Complementary color pigment paste 20 parts;

[0056] Wherein, the component of described white paint and the weight ratio that share are as follows:

[0057] Acrylic emulsion 36 parts;

[0058] 16 parts of titanium dioxide;

[0059] 2.4 parts of talcum powder;

[0060] 3.2 parts of hollow glass microspheres;

[0061] 5.6 parts of heavy calcium carbonate;

[0062] 4 parts of far-infrared ceramic powder;

[0063] 0.8 parts of dispersant;

[0064] 0.8 parts of wetting agent;

[0065] 0.8 part of defoamer;

[0066] Leveling agent 0.8 part;

[0067] 0.8 part of film-forming aid;

[0068] 8.8 parts of water;

[0069] The components of the complementary color pigment mill paste and the proportions by weight are as follows:

[0070] 12 parts of water;

[0071] 7 parts of complementary color pigments...

Embodiment 2

[0076] A kind of gray solar heat reflection cooling paint, is characterized in that:

[0077] By component and parts by weight proportioning is:

[0078] 85 parts of white paint;

[0079] Complementary color pigment paste 15 parts;

[0080] Wherein, the component of described white paint and the weight ratio that share are as follows:

[0081] 38.2 parts of acrylic emulsion;

[0082] 17 parts of titanium dioxide;

[0083] 2.6 parts of talcum powder;

[0084] 3.6 parts of hollow glass microspheres;

[0085] 6 parts of heavy calcium carbonate;

[0086] 4.3 parts of far-infrared ceramic powder;

[0087] Dispersant 0.9 parts;

[0088] 0.8 parts of wetting agent;

[0089] 0.9 part of defoamer;

[0090] Leveling agent 0.9 part;

[0091] 0.8 part of film-forming aid;

[0092] 9 parts of water;

[0093] The components of the complementary color pigment mill paste and the proportions by weight are as follows:

[0094] 11.7 parts of water;

[0095] 3 pairs of complementar...

Embodiment 3

[0100] A kind of gray solar heat reflection cooling paint, is characterized in that:

[0101] By component and parts by weight proportioning is:

[0102] 99 parts of white paint;

[0103] Complementary color pigment paste 1 part;

[0104] Wherein, the component of described white paint and the weight ratio that share are as follows:

[0105] Acrylic emulsion 44 parts;

[0106] 19 parts of titanium dioxide;

[0107] 3 parts talcum powder;

[0108] 3 parts of hollow glass microspheres;

[0109] 6 parts of heavy calcium carbonate;

[0110] 5 parts of far-infrared ceramic powder;

[0111] 1 part of dispersant;

[0112] 1 part of wetting agent;

[0113] 1 part of defoamer;

[0114] Leveling agent 1 part;

[0115] 1 part of film-forming aid;

[0116] 14 parts of water;

[0117] The components of the complementary color pigment mill paste and the proportions by weight are as follows:

[0118] 0.6 parts of water;

[0119] 0.2 parts of complementary color pigments;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com