Completely-biodegrading low-mobility-plasticizer polylactic acid material and preparation method thereof

A polylactic acid material, biodegradation technology, applied in the field of polymer materials and its preparation, can solve the problem of long-term use of unfavorable materials, not completely solve the mechanical properties, migration resistance and complete biodegradation properties of modified polylactic acid materials, mechanical properties Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

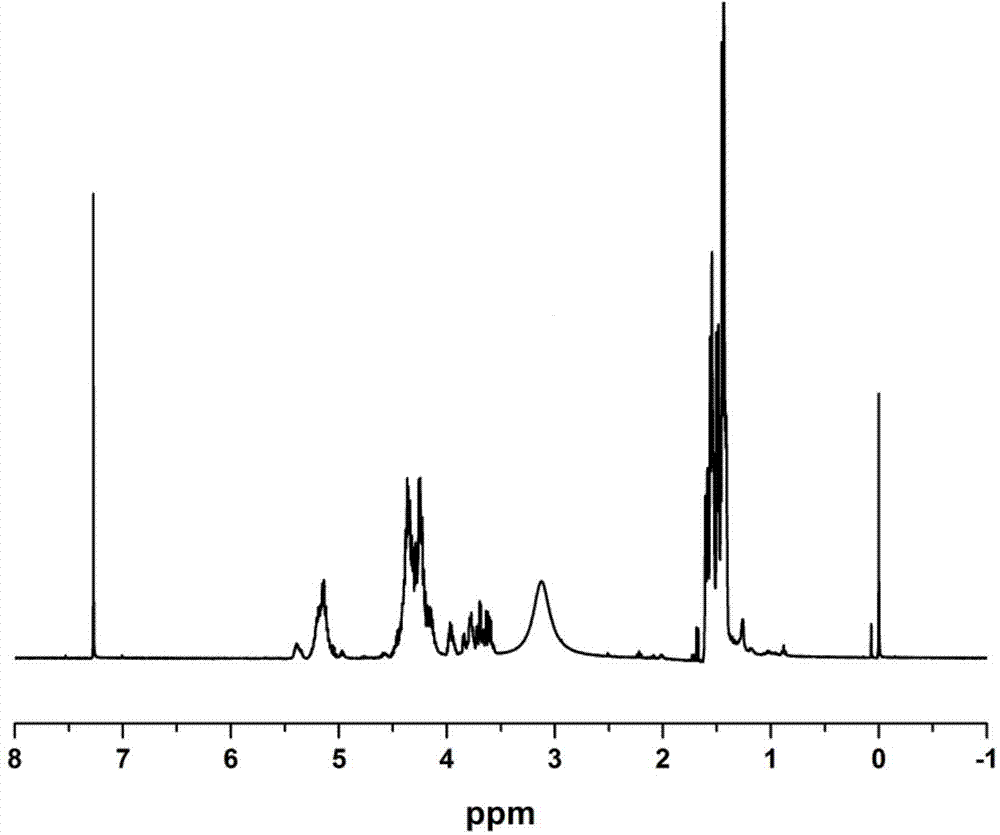

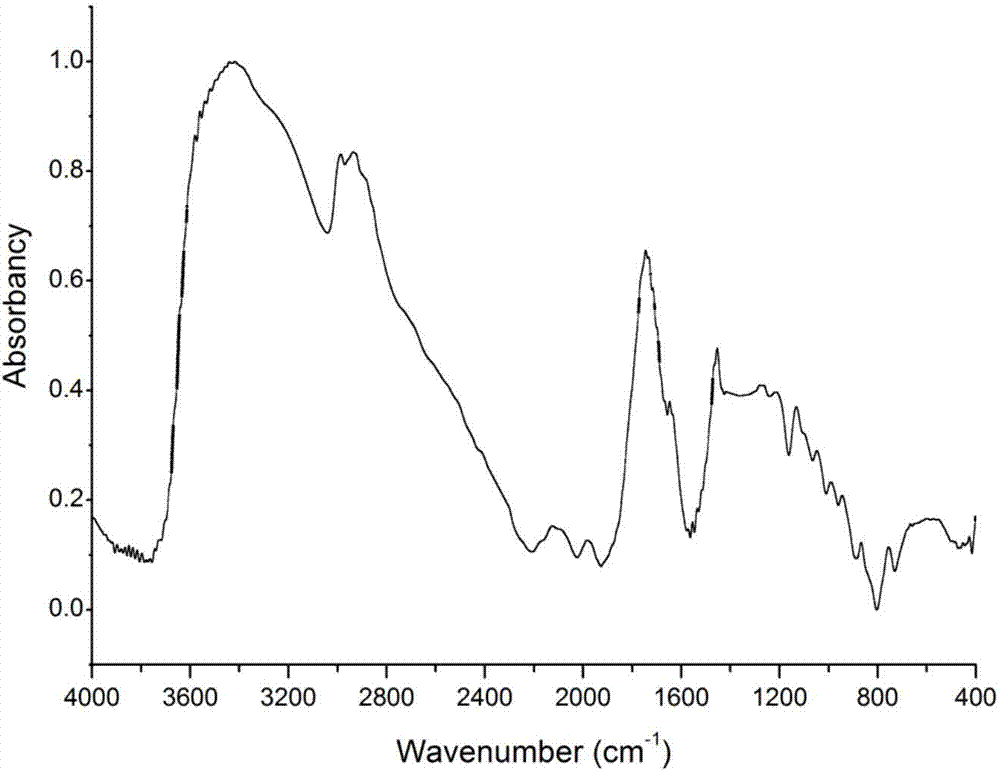

[0042] Blend glycerin and lactic acid in a reaction flask at a molar ratio of 1:3.1, add a water-carrying agent with a total mass of 2% and a catalyst with a mass of 0.1% glycerin, and stir for 3 hours at a temperature of 250°C, and then at a temperature of 220°C, The vacuum degree is 20kPa, and the water-carrying agent and unreacted small molecules are removed to obtain a low-migration plasticizer.

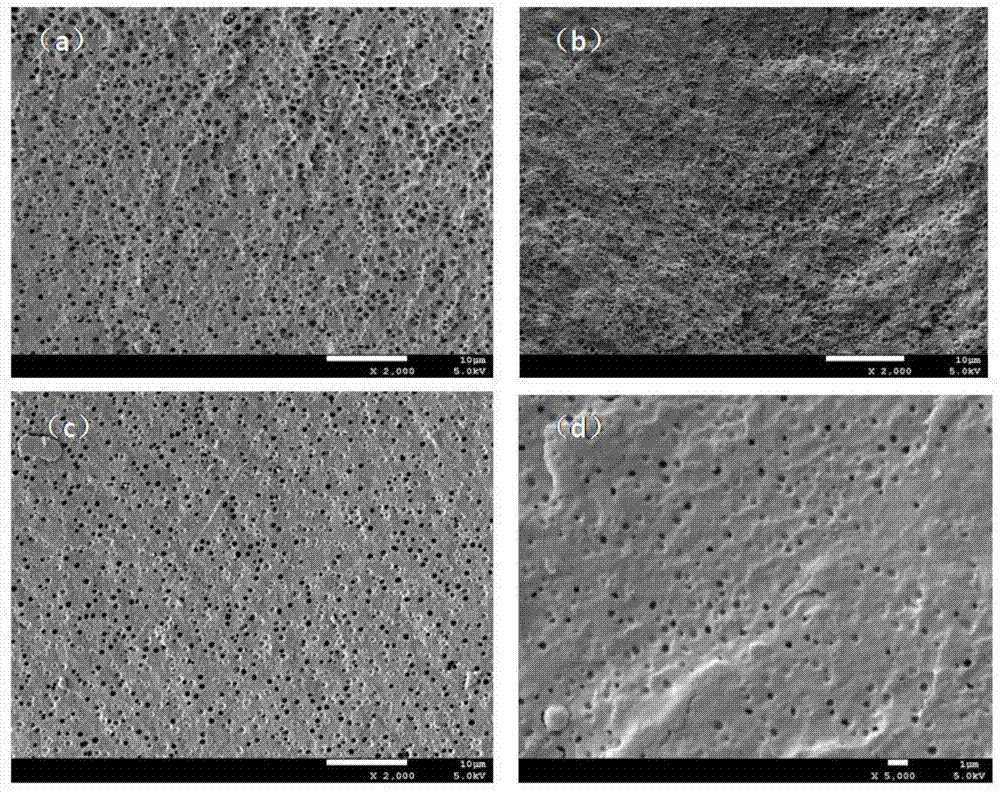

[0043] According to the ratio of 100 parts by weight of polylactic acid and 5 parts by weight of low-migration plasticizer, use an internal mixer at a temperature of 220 ° C and a speed of 45 rpm to carry out banburying and blending for 3 minutes to obtain a fully biodegradable low Plasticizer Migrating Polylactic Acid Materials. Its tensile strength is 33.11MPa, its elongation at break is 500.74%, its plasticizer volatilization loss rate at 125°C is 2.42%, and its plasticizer volatilization loss rate at 150°C is 9.14%.

Embodiment 2

[0045] Blend glycerol and lactic acid in a reaction flask at a molar ratio of 1:3.5, add a water-carrying agent with a total mass of 4% and a catalyst with a mass of 0.5% glycerin, and stir the reaction for 5 hours at a temperature of 180°C, and then at a temperature of 160°C, The vacuum degree is 9kPa, and the water-carrying agent and unreacted small molecules are removed to obtain a low-migration plasticizer.

[0046] According to the ratio of 100 parts by weight of polylactic acid and 10 parts by weight of low-migration plasticizer, use an internal mixer at a temperature of 210 ° C and a speed of 65 rpm to carry out banburying and blending for 4 minutes to obtain a fully biodegradable low Plasticizer Migrating Polylactic Acid Materials. The tensile strength is 33.22MPa, the elongation at break is 333.52%, the plasticizer volatilization loss rate is 2.53% at 125°C, and the plasticizer volatilization loss rate is 9.52% at 150°C.

Embodiment 3

[0048] Glycerin and lactic acid are blended in a reaction flask at a molar ratio of 1:2.5, and a water-carrying agent of 10% by mass and a catalyst of 2% by mass of glycerin are added, and the reaction is stirred at a temperature of 150°C for 15 hours, and then at a temperature of 140°C, The vacuum degree is 6kPa, and the water-carrying agent and unreacted small molecules are removed to obtain a low-migration plasticizer.

[0049] According to the ratio of 100 parts by weight of polylactic acid and 25 parts by weight of low-migration plasticizer, an extruder was used to blend at a temperature of 190°C for 7 minutes to obtain a completely biodegradable polylactic acid material with low plasticizer migration. The tensile strength is 37.29MPa, the elongation at break is 393.66%, the plasticizer volatilization loss rate is 3.11% at 125°C, and the plasticizer volatilization loss rate is 10.13% at 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com