Manufacturing method of polyimide resin and polyimide film manufactured using the same

A technology of polyimide resin and polyimide film, which is applied in the field of manufacturing method and the manufacture of polyimide film and resin, which can solve the problems of low thermal stability of plastic substrates and increased demand , to achieve the effect of excellent thermal stability, good thermal stability performance and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

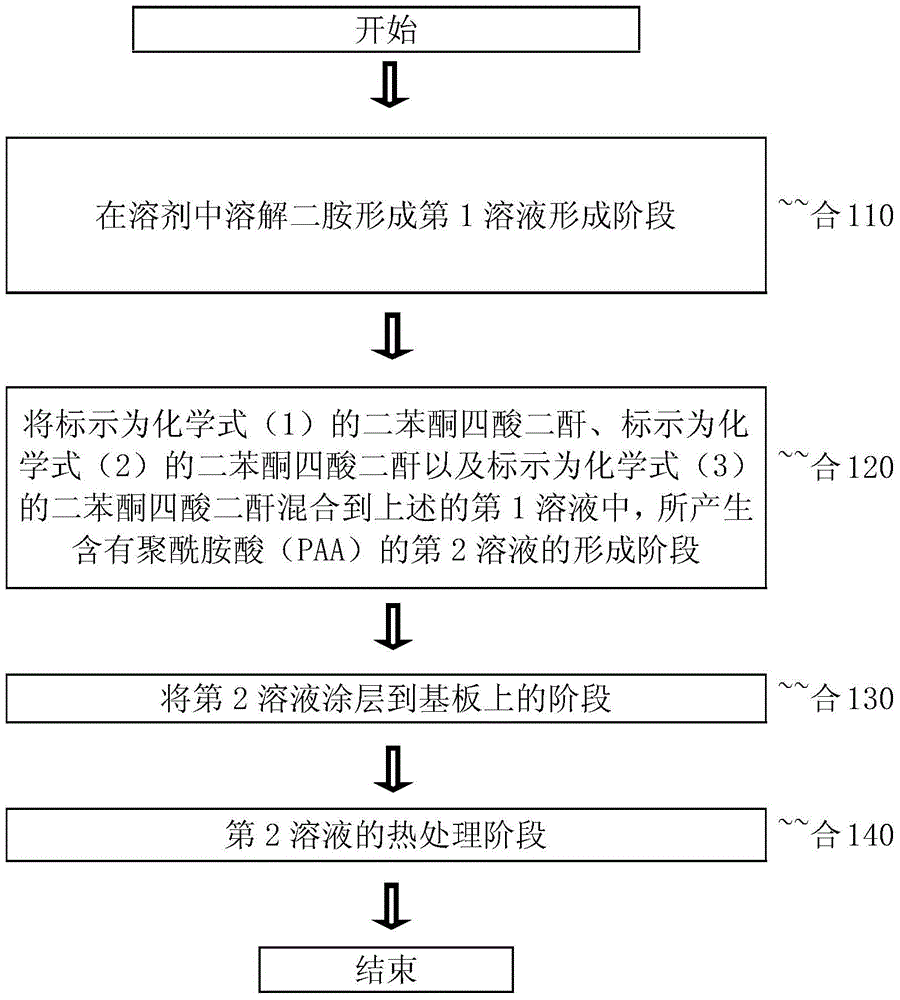

[0041] Prepare a reactor with an attached stirrer, nitrogen injector, dropping funnel, temperature regulator, and condenser. Nitrogen gas was injected into the above reactor, and 5.97000 mol of DMAC solvent was put into it. The temperature of the reactor was kept below 20° C., and 0.20000 mol of 2,2′-bis(trifluoromethyl)-4,4′-diaminobiphenyl (2,2′-TFDB) was dissolved. Put 0.15mol of benzophenone tetra-acid dianhydride marked as chemical formula (1), 0.02299 mol of benzophenone tetra-acid dianhydride marked as chemical formula (2), and 0.04269 mol of benzophenone tetra-acid dianhydride marked as chemical formula (3) in the above reactor of benzophenone tetracarboxylic dianhydride. After 24 hours of reaction, a colorless and transparent polyamic acid with a viscosity in the range of 1000-2000 cps and a cure rate of 22 wt % was obtained.

[0042] Spin coating colorless and transparent polyamic acid solution on the substrate and heat treatment. First, the temperature was increa...

Embodiment 2

[0045] Prepare a reactor with an attached stirrer, nitrogen injector, dropping funnel, temperature regulator, and condenser. Inject nitrogen gas into the above reactor, and put 5.97000 mol of N-methyl-2-pyrrolidone (NMP) m-cresol solvent. The temperature of the reactor was kept below 20° C., and 0.20000 mol of 3,3′-bis(trifluoromethyl)-4,4′-diaminobiphenyl (33′-TFDB) was dissolved. Put 0.15000mol of benzophenone tetra-acid dianhydride marked as chemical formula (1), 0.02299 mol of benzophenone tetra-acid dianhydride marked as chemical formula (2) in the above reactor, and 0.04269 mol marked as chemical formula (3) of benzophenone tetracarboxylic dianhydride. After 24 hours of reaction, a colorless and transparent polyamic acid with a viscosity in the range of 1000-2000 cps and a cure rate of 22 wt % was obtained.

[0046] The colorless and transparent polyamic acid solution Doctorblade is coated on the substrate and then heat treated. First, the temperature was increased to...

Embodiment 3

[0050] Prepare a reactor with an attached stirrer, nitrogen injector, dropping funnel, temperature regulator, and condenser. Nitrogen gas was injected into the above reactor, and 5.97000 mol of DMSO solvent was put into it. Keep the temperature of the reactor below 20°C and dissolve 0.20000mol of 4,4'-amine oxidase. Put 0.15000mol of benzophenone tetra-acid dianhydride marked as chemical formula (1), 0.02299 mol of benzophenone tetra-acid dianhydride marked as chemical formula (2) in the above reactor, and 0.04269 mol marked as chemical formula (3) of benzophenone tetracarboxylic dianhydride. After 24 hours of reaction, a colorless and transparent polyamic acid with a viscosity in the range of 1000-2000 cps and a cure rate of 22 wt % was obtained.

[0051] The colorless and transparent polyamic acid solution Slotdie is coated on the substrate and then heat treated. First, the temperature was increased to 120° C., and the solvent was evaporated for 5 minutes to obtain solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com