Technology and device for recycling chloroethylene high-boiling substance

A technology for vinyl chloride and high boiling substances, which is applied in the recovery process and equipment, vinyl chloride high boiling substances recovery process and equipment fields, and can solve the problem of poor separation effect of vinyl chloride, poor separation effect of high boiling substances, and large waste discharge and other problems, to achieve the effect of simple structure, considerable economic benefits and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

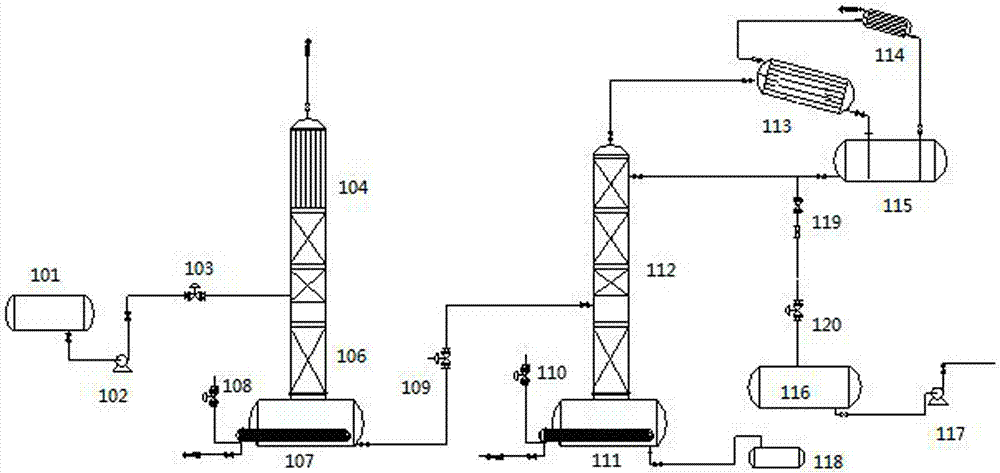

[0045] Examples such as image 3 Shown, a kind of vinyl chloride high boiler recovery process and equipment thereof, described recovery process comprises the following steps:

[0046] (1) Material storage and inspection.

[0047] The vinyl chloride high boiler is sent into the high boiler storage tank 101, and the main components in the vinyl chloride high boiler are 1,1-dichloroethane, trans 1,2-dichloroethylene, cis 1,2- Dichloroethylene, vinylidene chloride, trichloroethylene, 1,1,2-trichloroethane and vinyl chloride content.

[0048]The test results show that the content of 1,1-dichloroethane is 52%, the content of trans-1,2-dichloroethylene is 17%, the content of cis-1,2-dichloroethylene is 3.5%, and the content of dichloroethylene The content of ethylene is 0.7%, the content of trichloroethylene is 0.3%, the content of 1,1,2-trichloroethane is 9%, the content of vinyl chloride is 17.4% and other trace unknown components.

[0049] (2) Feeding.

[0050] The vinyl chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com