Attraction and removing equipment for clearing away magnetic impurities in scrap silicon materials

A technology of magnetic impurities and equipment is applied in the field of suction and removal devices for removing magnetic impurities from waste silicon materials for solar silicon wafer production. problem, to achieve the effect of complete suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

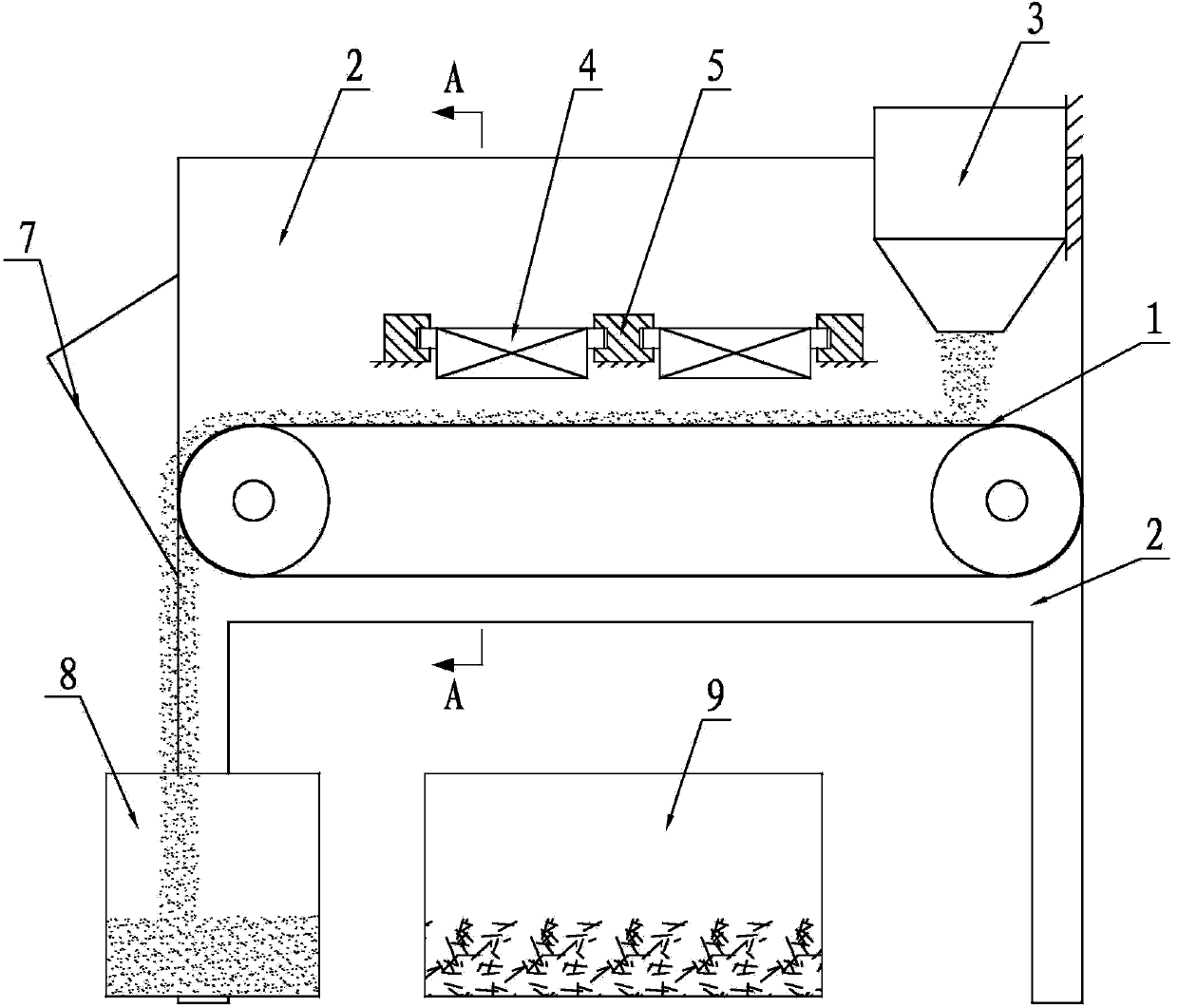

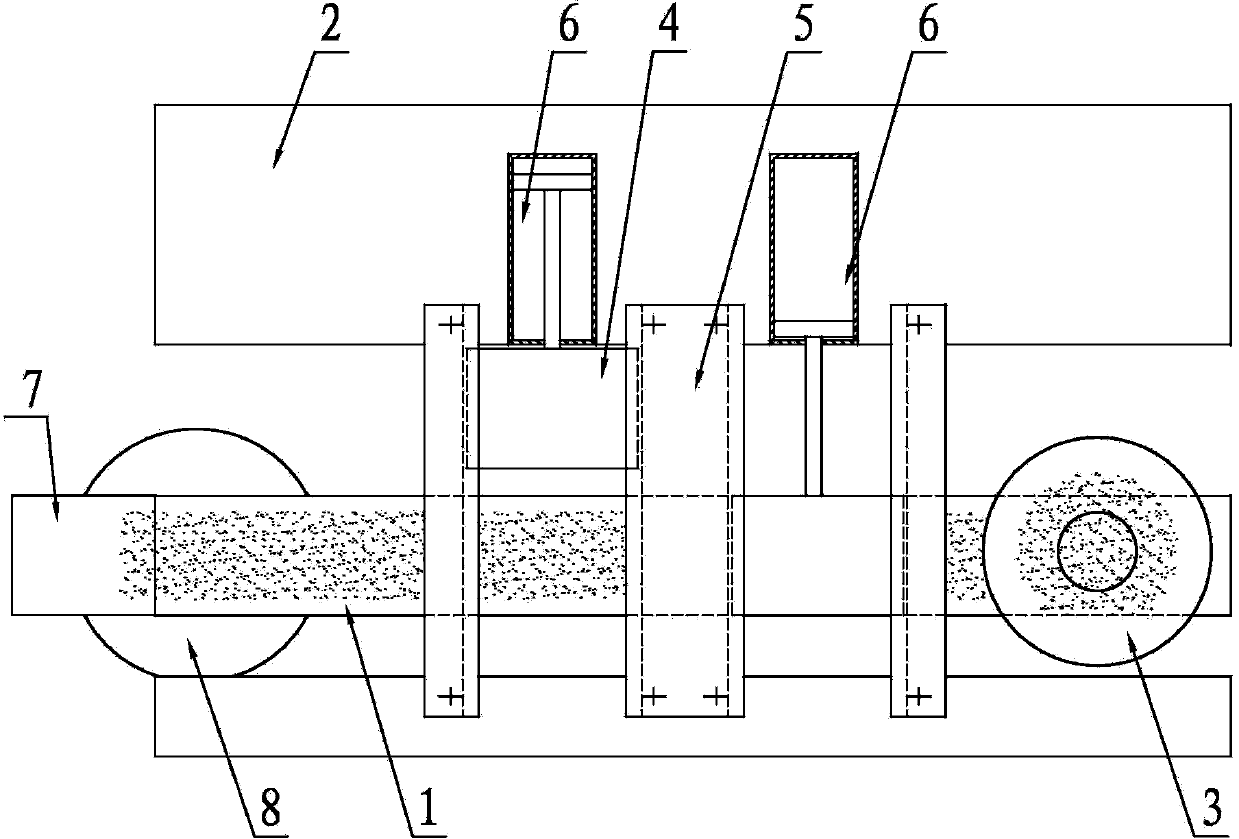

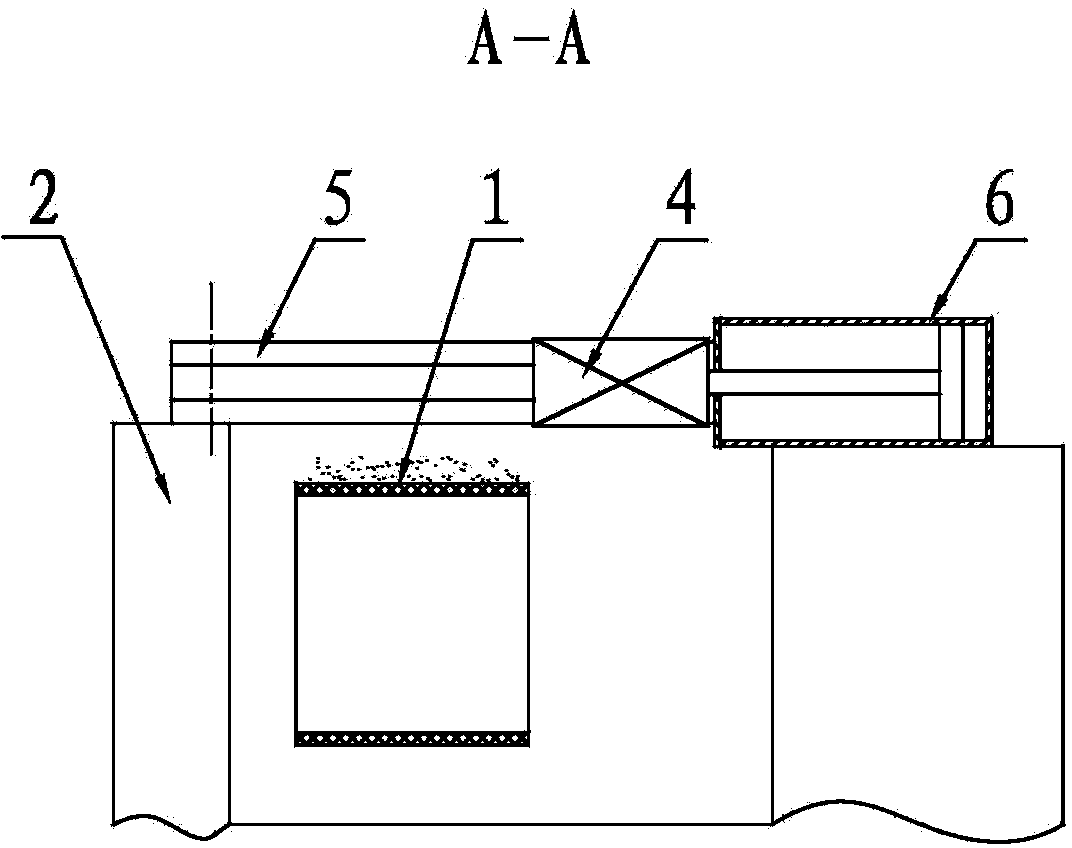

[0022] Embodiment 1: A kind of gettering equipment for removing magnetic impurities in waste silicon material, such as Figure 1 ~ Figure 3 As shown, it includes a conveyor belt 1 set horizontally, a frame 2, a storage hopper 3, two electromagnetic iron absorbing blocks 4, three horizontal linear slide rails 5 and two driving cylinders 6, and the three horizontal linear slide rails 5 are fixed in parallel and at intervals On the frame 2, all horizontal linear slide rails 5 are located above the conveyor belt 1, and are perpendicular to the conveying direction of the conveyor belt 1, and two adjacent horizontal linear slide rails 5 form a slideway for installing the electromagnetic iron-absorbing block 4, Two electromagnetic iron absorbing blocks 4 are slidably installed on the slideways respectively, and the cylinder bodies of two driving cylinders 6 are fixed on the frame 2, and each driving cylinder 6 corresponds to an electromagnetic absorbing iron block 4, and the piston of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com