A kind of electrofiltration membrane and its preparation method and application

A technology of electrofiltration membrane and filtration membrane, which is applied in the field of electrofiltration membrane, can solve the problems of small surface charge of charged membrane and inability to effectively suppress the effect of concentration polarization, and achieve small molecular weight cut-off, suppression of concentration polarization and Effects of membrane fouling and increase in transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

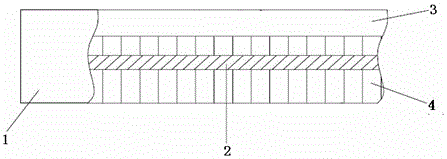

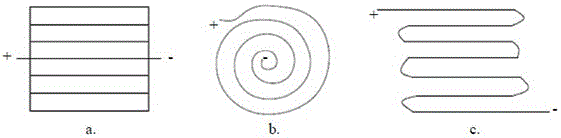

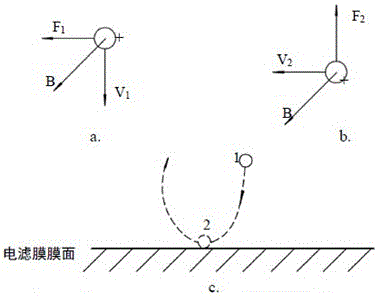

[0032]Example 1: The electrofiltration membrane is composed of bisphenol A polysulfone (PSF) and copper wire (diameter: 30 μm; specific resistance: 1.75 × 10 -8 Ω·cm) is made by the immersion gel phase inversion method, and the copper wires are arranged at a distance of 1 mm. In this embodiment, the electrofiltration membrane is connected to a single electrode for filtering dextran sulfate.

[0033] The preparation method of above-mentioned electrofiltration membrane is as follows:

[0034] (1) Put bisphenol-A polysulfone, dimethylformamide, and N-methyl-2-pyrrolidone in a reaction kettle at 80°C and mix and stir for 4 hours until completely dissolved, press filter and stand for 24 hours for defoaming , the casting solution is obtained, wherein the additions of polymer, solvent and additive are respectively 21%, 77%, 2% by the percentage of the total mass of the composition;

[0035] (2) Evenly arrange the copper wires on the glass plate fixed with non-woven fabric, the dista...

Embodiment 2

[0042] Example 2: The electrofiltration membrane is made of polyacrylonitrile (PAN) and tungsten wire (diameter: 20μm; specific resistance: 5.4×10 -8 Ω·cm) is made by the immersion gel phase inversion method, and the tungsten wires are arranged at a distance of 5mm. In this embodiment, the electrofiltration membrane is connected to a single electrode, and the opposite electrode is placed near the membrane surface of the electrofiltration membrane. Dextran sulfate was filtered.

[0043] The preparation method of above-mentioned electrofiltration membrane is as follows:

[0044] (1) Put polyacrylonitrile, N-methylpyrrolidone and dimethylacetamide in a reaction kettle and mix and stir for about 5 hours until they are completely dissolved at 70°C. After pressure filtration, stand for degassing for 30 hours to obtain a casting film solution , wherein by the percentage of the total mass of the composition, the additions of the polymer, the solvent, and the additive are respectively...

Embodiment 3

[0052] Example 3: The electrofiltration membrane is made of polyvinyl chloride (PVC) and stainless steel wire (diameter: 50μm; specific resistance: 7×10 -7 Ω·cm) is made by the immersion gel phase inversion method, and the stainless steel wires are arranged at a distance of 2 mm. In this embodiment, the electrofiltration membrane is passed through an electric current to filter dextran sulfate;

[0053] The preparation method of above-mentioned electrofiltration membrane is as follows:

[0054] (1) Put polyvinyl chloride, dimethyl sulfoxide and formamide in a reactor at 50°C and mix and stir for about 4 hours until they are completely dissolved. After pressure filtration, let stand for degassing for 15 hours to obtain a casting solution. In terms of the percentage of the total mass of the composition, the additions of the polymer, the solvent, and the additive are respectively 25%, 74%, and 1%;

[0055] (2) Evenly arrange stainless steel wires with a diameter of 50 μm on a gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com