Direct torque control device and method for asynchronous motor

A direct torque control, asynchronous motor technology, used in motor generator control, AC motor control, electronically commutated motor control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

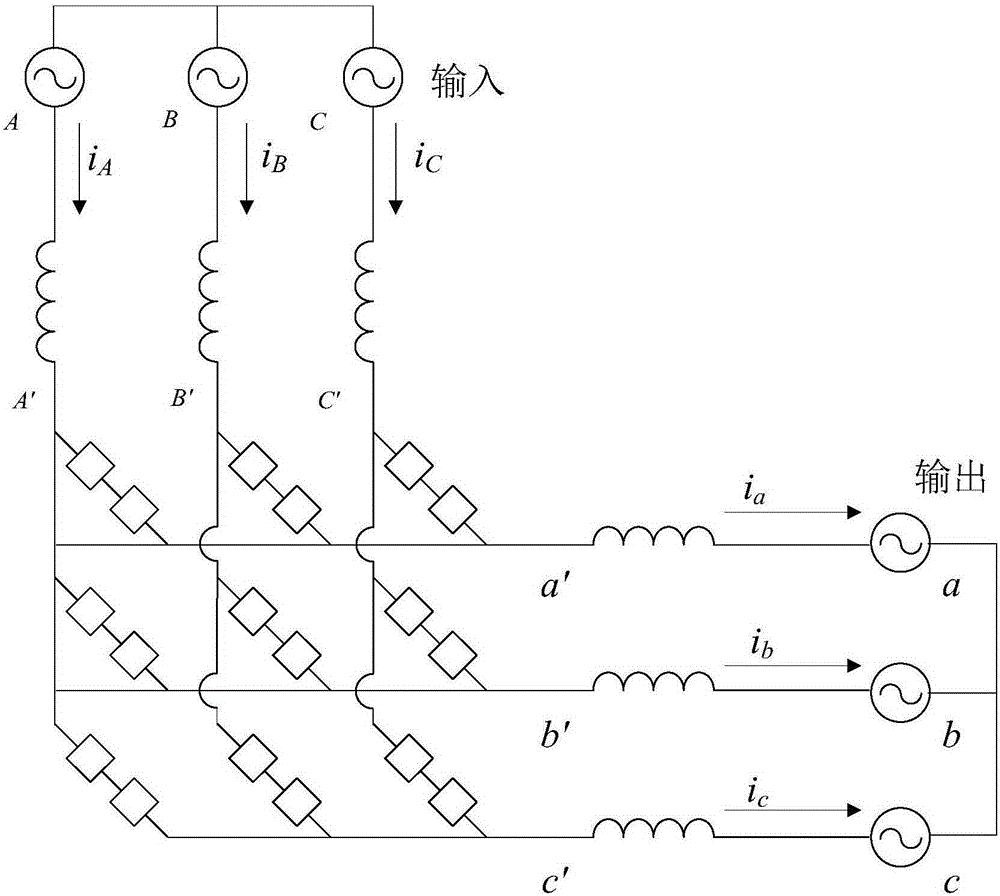

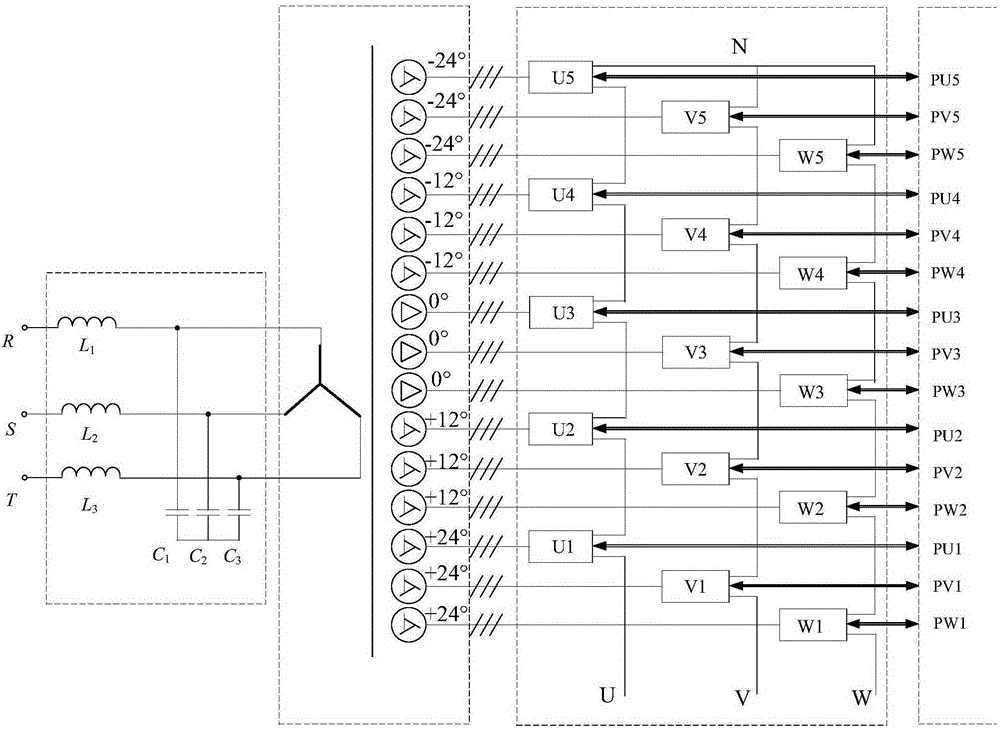

[0056] The direct torque control device of the asynchronous motor of the present invention, refer to Figure 10 , including asynchronous motors and high-voltage matrix inverters, refer to Figure 8 , that is to connect the three output terminals U, V, W of the high-voltage matrix inverter with an asynchronous motor. The high-voltage matrix inverter includes a phase-shifting isolation transformer, a matrix transformation unit array and a general controller, among which:

[0057] 1) Phase-shifting isolation transformer

[0058] refer to Figure 8 , The phase-shifting isolation transformer has 3n three-phase secondary windings, n is a natural number, every 3 secondary windings form a group and have the same phase, the phases of each group of secondary windings increase in turn, the initial phase is 0°, adjacent The phase difference between them is 60 / n degrees. In the embodiment of the high-voltage matrix converter of the present invention, n is a natural number 3. The three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com