Hybrid excitation fault tolerant motor system based on automatic position detection

A hybrid excitation and self-testing technology, applied in the direction of motors, control systems, control generators, etc., can solve the problems of reducing system reliability and increasing control system costs, so as to solve the problem of zero-low speed operation and improve reliability and fault tolerance , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

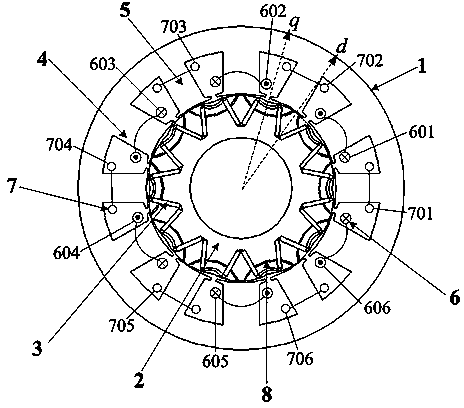

[0022] like figure 1 Shown is a hybrid excitation fault-tolerant motor based on position self-detection, specifically a three-phase 12-slot / 10-pole motor, including stator 1, rotor 2, permanent magnet 3, armature teeth 4, fault-tolerant teeth 5, armature Coil 6, excitation coil 7 and magnetic isolation layer 8. The armature teeth 4 and the fault-tolerant teeth 5 are evenly distributed along the inner ring of the stator 1, the total number of teeth is a multiple of 2m (m is the number of phases of the motor), and the tooth width of the armature teeth 4 and the tooth width of the fault-tolerant teeth 5 are different. equal. The permanent magnet 3 is embedded in the rotor 2. The permanent magnet 3 is composed of two magnetic strips that are radially symmetrical along the rotor at one end close to the rotor axis. The shape is "V", so that the permanent magnet has both ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com