Distribution automation terminal core unit capable of achieving direct cool starting at -40 DEG C

A power distribution automation and cold start technology, applied in electrical components, circuit devices, sustainable buildings, etc., can solve problems such as failure to start normally, affect the promotion and construction of power distribution automation systems, and achieve the effect of improving low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

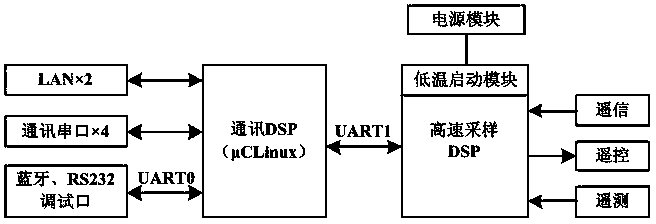

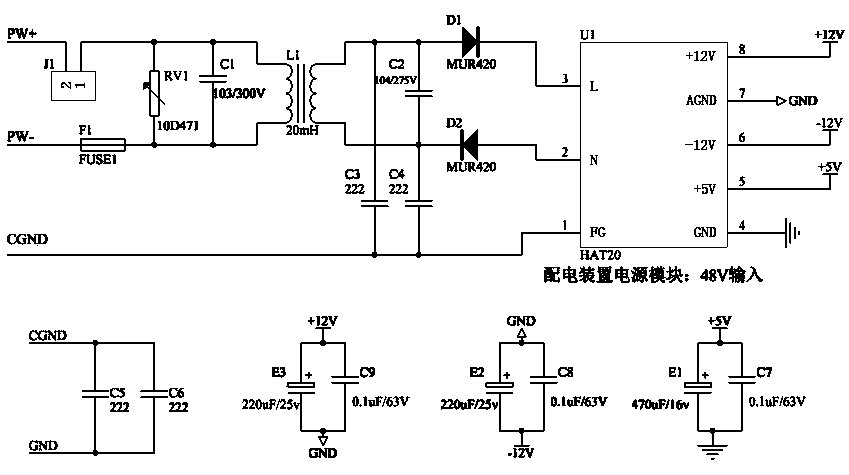

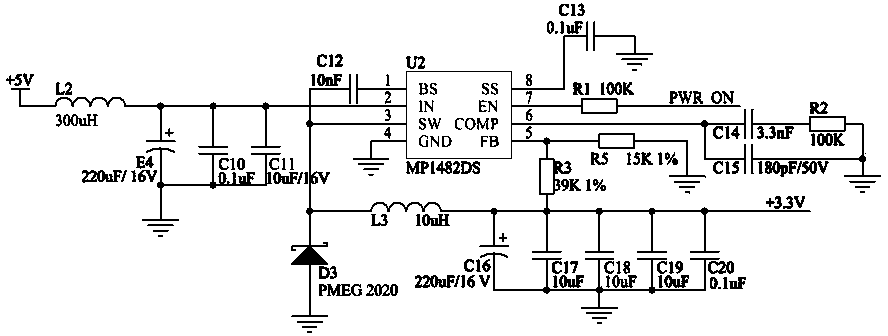

[0009] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, a distribution automation terminal core unit that can be directly cold-started at -40°C is composed of a power supply module, a follow-up application circuit and a high-speed sampling module. The output of the power supply module is directly connected to the follow-up application circuit. It is characterized in that: The output of the high-speed sampling module is connected to the low-temperature start-up module and connected to the power module, DC48V input, after the power module outputs ±12V, 5V, and the output 5V port is connected to a voltage stabilizing circuit composed of L2, E4, C10, and C11. The voltage stabilizing circuit is composed of capacitors C10, C11 and capacitor E4 connected in parallel, and then connected in series with the inductor L2; through this voltage stabilizing circuit, the DC conversion chip U2 is powered. When the 5V output o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com