Petroleum drilling machine direct current micro-grid system

A DC micro-grid and drilling rig technology, applied in the field of oil drilling rig equipment, can solve problems such as difficulty in meeting the power requirements of the parallel car box, and achieve the effects of reducing engine capacity, large torque, wide low speed, and wide speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

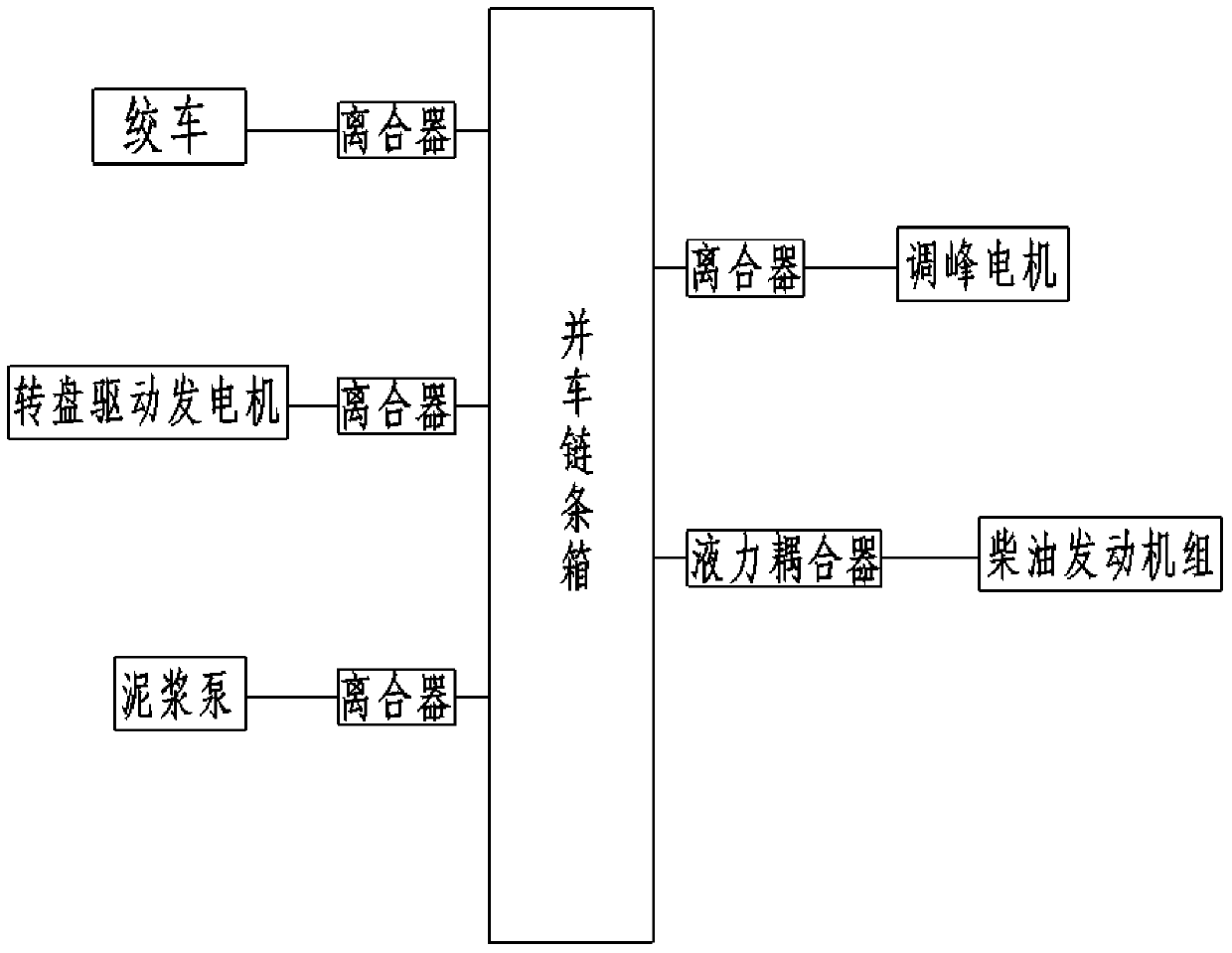

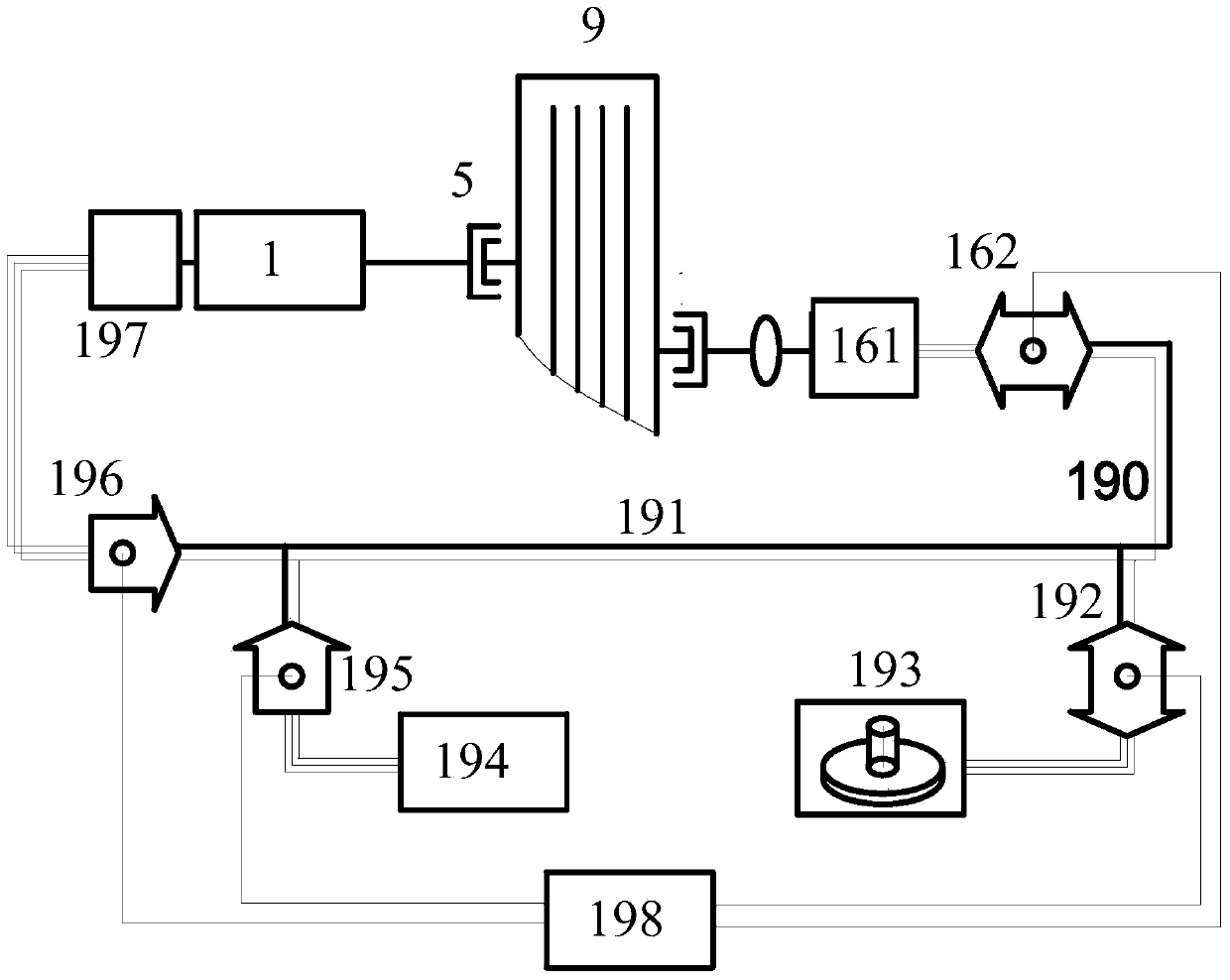

[0014] combined with figure 1 , 2 , the present invention includes a power system, a transmission system, and a DC micro-grid system. The DC micro-grid system includes a peak-shaving device, a micro-power supply and a control device, and the peak-shaving device includes a peak-shaving motor and a flywheel energy storage device. The DC bus and converter are connected to the flywheel energy storage device.

[0015] Described micro-power supply is winch energy recovery device 197, is made up of electromagnetic braking brake, generator, one end of electromagnetic braking brake is connected with winch 1 through clutch 5, and its other end is through speed-up box, generator, winch energy recovery device rectifier 196, And connect to the connection line 190 between the flywheel energy storage device 193 and the peak regulation motor 161 through the DC bus 191, the peak regulation motor bidirectional converter 162, the flywheel energy storage device bidirectional converter 192, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com