Metering monitoring management system and implementation method thereof

A technology for monitoring management and implementation methods, applied in the field of logistics management, can solve problems such as easy leakage of demand and supplier information, difficulty in tracing errors, restricting fast-paced production, etc., to achieve a balanced traffic rate, improve core competitiveness, and improve The effect of overall work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

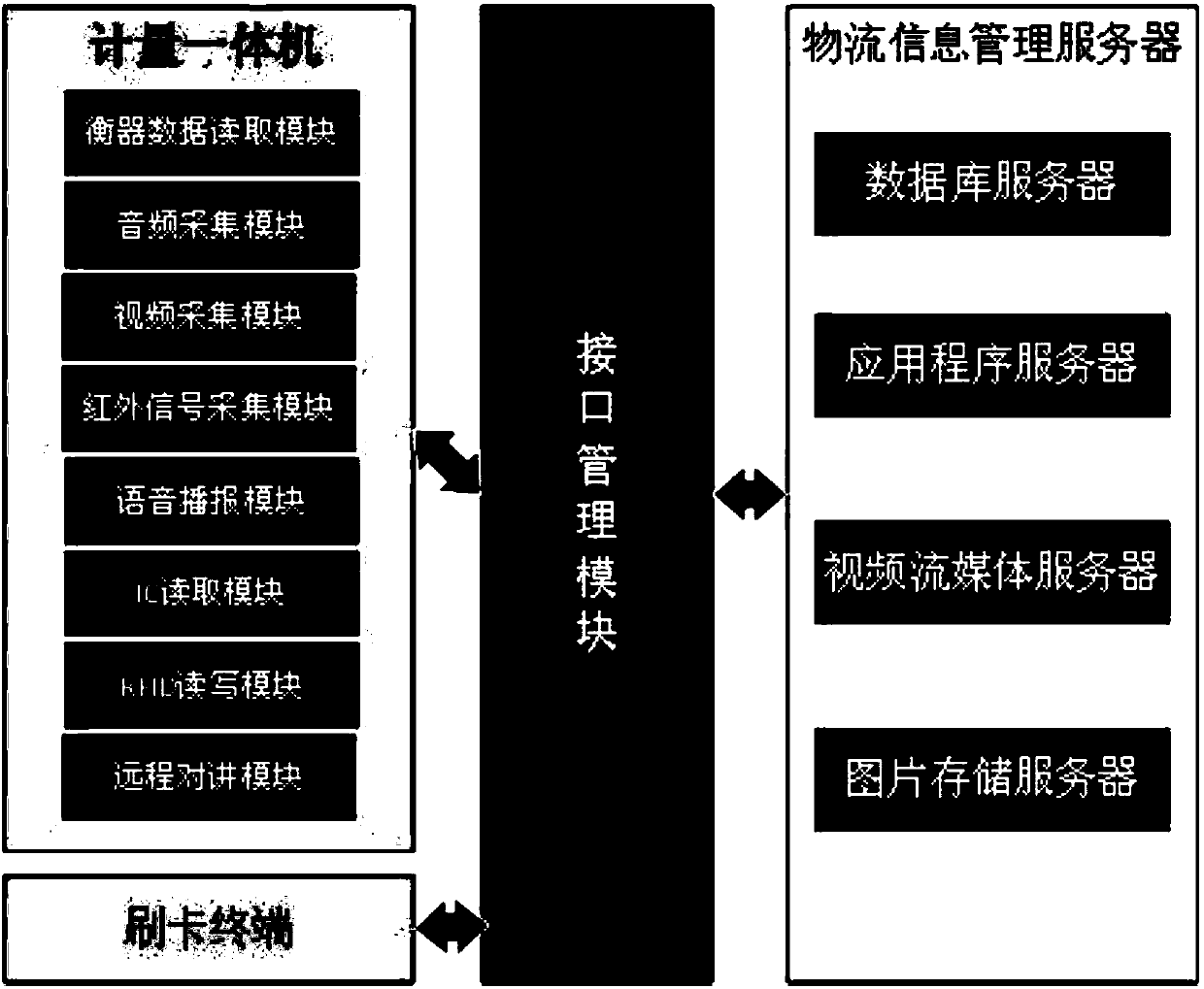

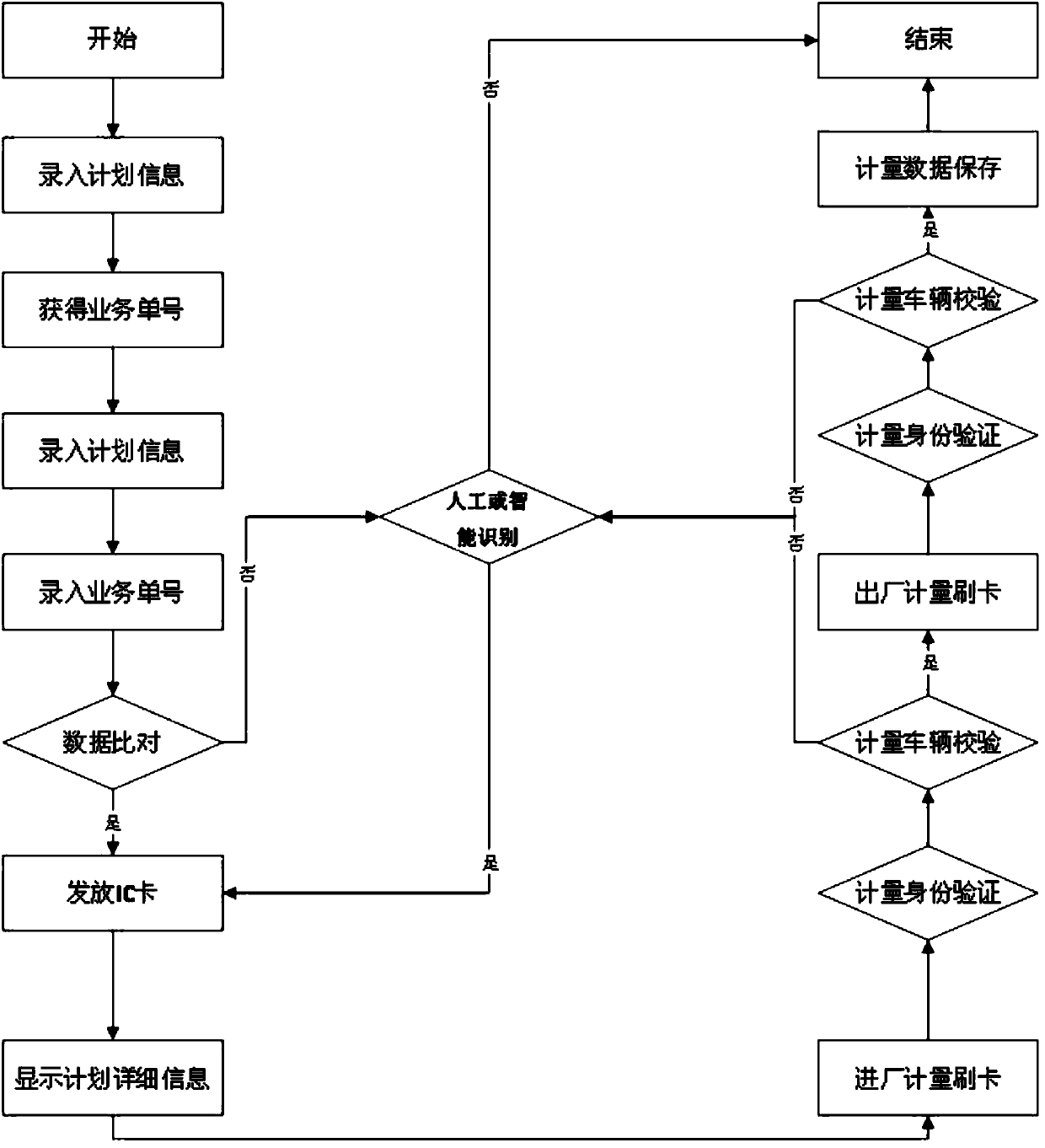

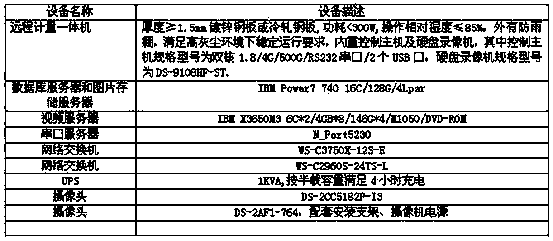

[0025] A metering monitoring and management system such as figure 1 As shown, it includes the card swiping terminal, the metering all-in-one machine located in the weighing room of the warehouse, etc., and the information management server that provides data support for the card swiping terminal and the metering all-in-one machine. The metering all-in-one machine and the card swiping terminal are respectively connected to the logistics information management server . The remote all-in-one machine includes weighing instrument data reading module, audio collection module, video collection module, infrared signal collection and judgment module, voice broadcast module, IC reading module, RFID reading and writing module and remote intercom module, any one on the metering all-in-one machine The modules can be communicated with the logistics information management server through the interface management module; there are 5 cameras connected to the video acquisition module, one for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com