Test board for magnetic motor

A test bench, magneto technology, applied in the direction of motor generator testing, measuring device casing, etc., can solve the problems of insufficient magneto protection, prone to off-axis, affecting testing, etc., to improve the use range, improve the test range, and facilitate The effect of the installation test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

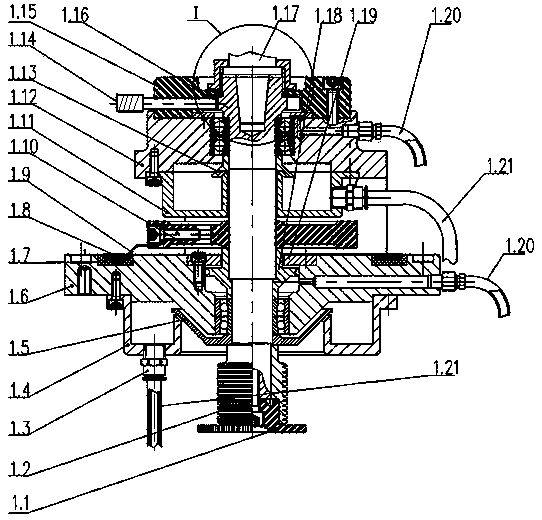

[0030] According to the accompanying drawings, the present invention specifically designs a magneto test bench, which is mainly used for the performance test of the magneto, including operating vibration, noise, output torque, speed, etc., calculation efficiency (combined with input electric power), and stalling , overspeed and other tests.

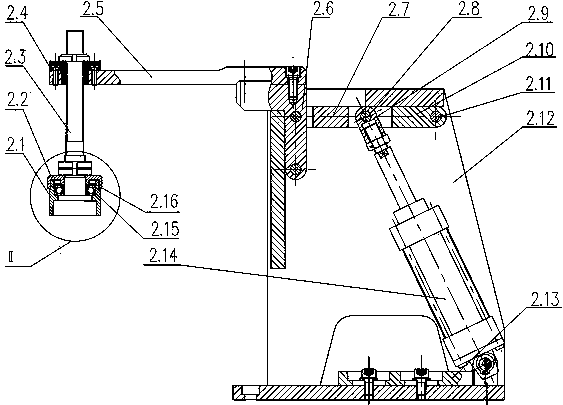

[0031] attached by figure 1 It can be seen that the test bench mainly includes a test head assembly 1, a protective arm assembly 2, a frame 3, an oil injection machine 4 and a motor 5, and a protective arm assembly 2 is arranged above the frame 3, and the upper surface of the frame 3 is installed There is a test head assembly 1, an oil injection machine 4 and a motor 5 are arranged inside the frame 3, the motor 5 drives the test head assembly 1 to rotate through a belt connection, and the oil injection machine 4 is connected to the test head assembly 1 for oil lubrication and For heat dissipation, the protective arm assembly 2 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com