Large-size roadway support laboratory simulation system and method

A laboratory simulation and roadway support technology, applied in the field of coal mine roadway support, can solve problems such as the inability to simulate impact and blasting disturbance roadways, the inability to realize large-scale roadway tests, and the inability of models to study roadway support forms and support parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

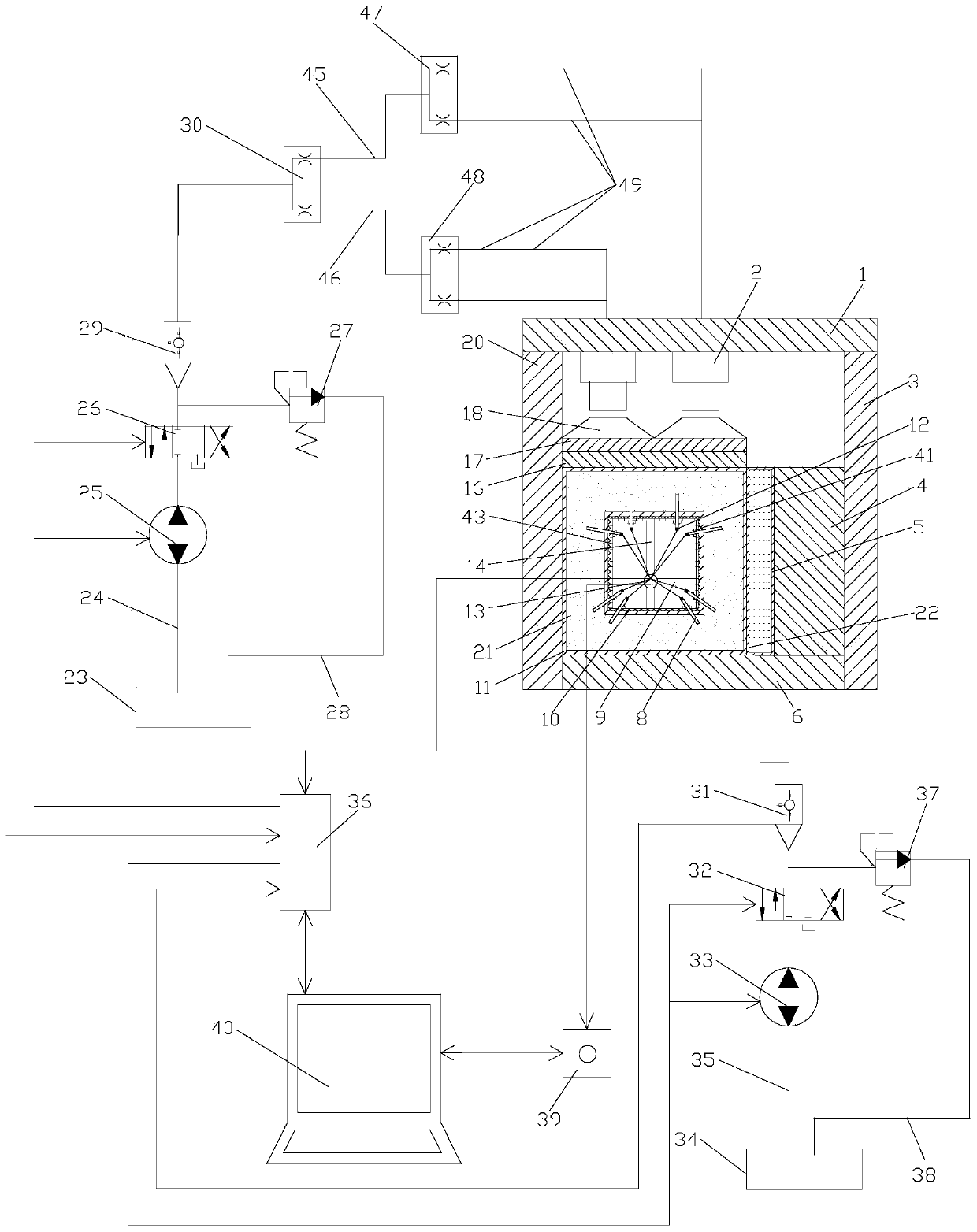

[0076] Such as figure 1 as well as Figure 4 ~ Figure 7 As shown, the large-scale roadway support laboratory simulation system of the present invention includes a large-scale roadway support simulation system, a pressurized force transmission system and a support data acquisition system,

[0077] The large-scale roadway support simulation system is composed of a large-scale roadway shape simulation mechanism and a support simulation mechanism. The large-scale roadway shape simulation mechanism includes a roadway model box 11 with a back-shaped cross section and a roadway model box 11 set in the middle channel of the roadway model box 11. A rubber ring 10 with a square cross section, the inside of the roadway model box 11 is filled with compacted similar simulation materials 21 for simulating the surrounding rock of the roadway; The square steel mesh 43 on the side wall and the top surface, and a plurality of rectangular steel plates 41 fixedly connected on the inner side wall...

Embodiment 2

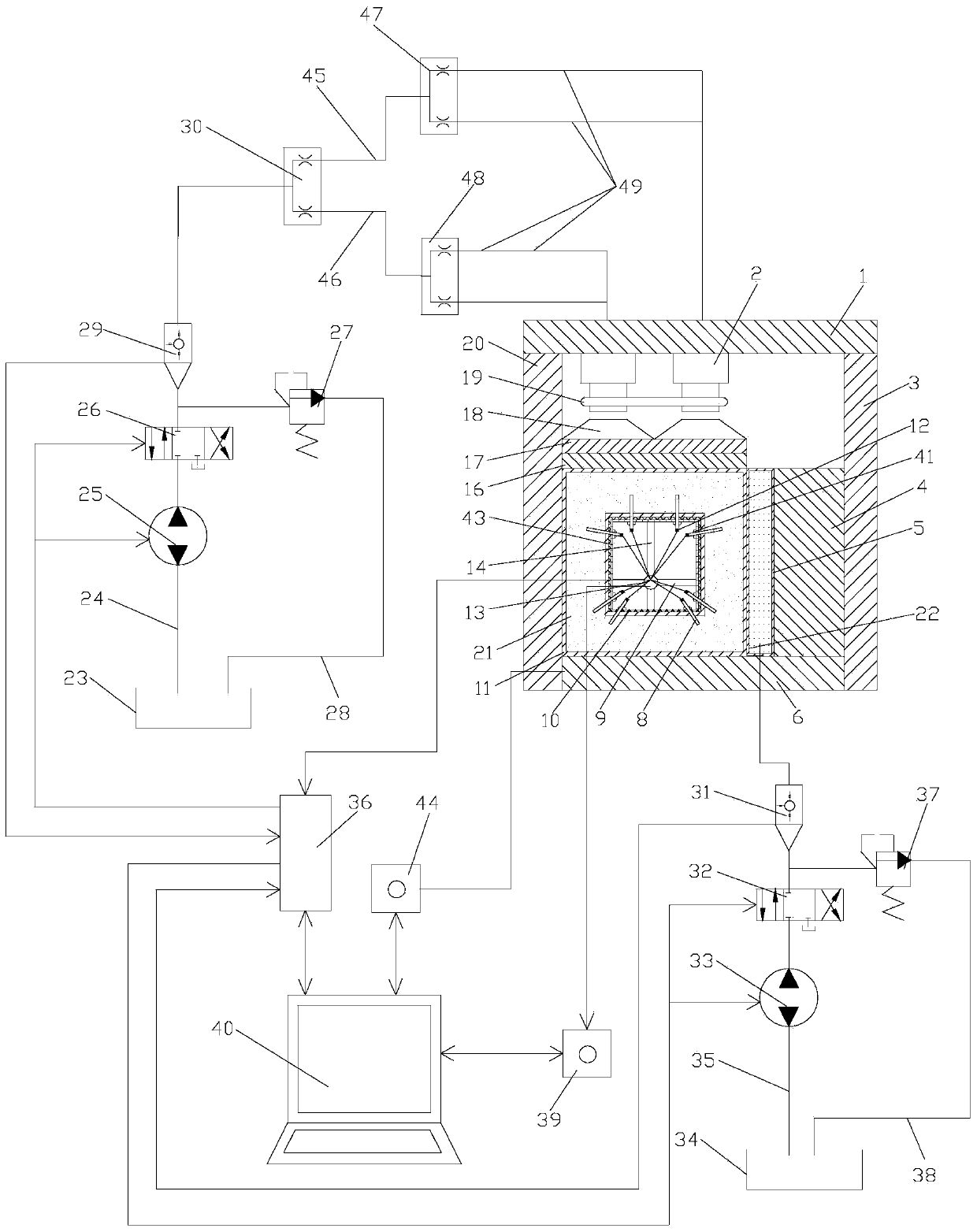

[0088] combine figure 2 and Figure 8 , the large-scale roadway support laboratory simulation system in this embodiment is different from Embodiment 1 in that: the present invention also includes impact steel rings 19 set on the periphery of four hydraulic jacks 2 and vibration signals for detecting vibration signals. A signal detection device 44 , the vibration-measuring speed sensor probe of the vibration signal detection device 44 is connected to the base 6 , and the vibration signal detection device 44 is connected to the computer 40 . The vibration signal detection device 44 is a TPBOX-508 type vibration signal self-recording instrument. All the other structures are the same as in Example 1.

[0089] The large-scale roadway support laboratory simulation method in the present embodiment is different from embodiment 1 in that:

[0090] Step 3: Apply lateral pressure and axial pressure to the surrounding rock of the roadway under impact disturbance, and collect and recor...

Embodiment 3

[0096] combine image 3 and Figure 8 , the large-scale roadway support laboratory simulation system in this embodiment is different from Embodiment 1 in that the present invention also includes a vibration signal detection device 44 for detecting vibration signals, and the base 6 is equipped with a roadway model Right below the box 11 is a blasting box 7 with a detonator inside. The vibration-measuring speed sensor probe of the vibration signal detection device 44 is connected to the base 6 , and the vibration signal detection device 44 is connected to the computer 40 . The vibration signal detection device 44 is a TPBOX-508 type vibration signal self-recording instrument. All the other structures are the same as in Example 1.

[0097] The large-scale roadway support laboratory simulation method in the present embodiment is different from embodiment 1 in that:

[0098] Step 3: Load lateral pressure and axial pressure to the surrounding rock of the roadway under blasting di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com