Combined Long Distance Shaft Sleeve Coaxiality Detector

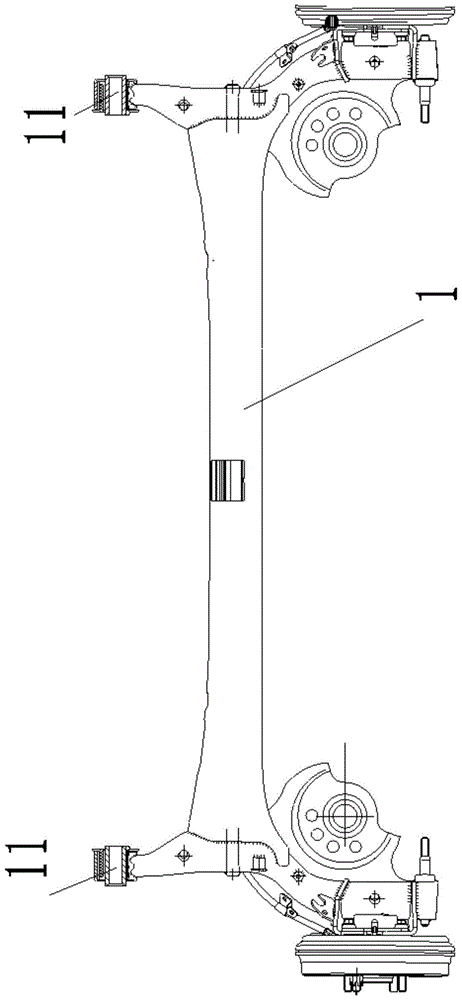

A technology of coaxiality and long spacing, applied in the field of combined long spacing bushing coaxiality detector, can solve the problems of large volume, heavy weight and damage of rear axle 1, achieve quick and convenient operation and reduce testing cost , cleverly conceived effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

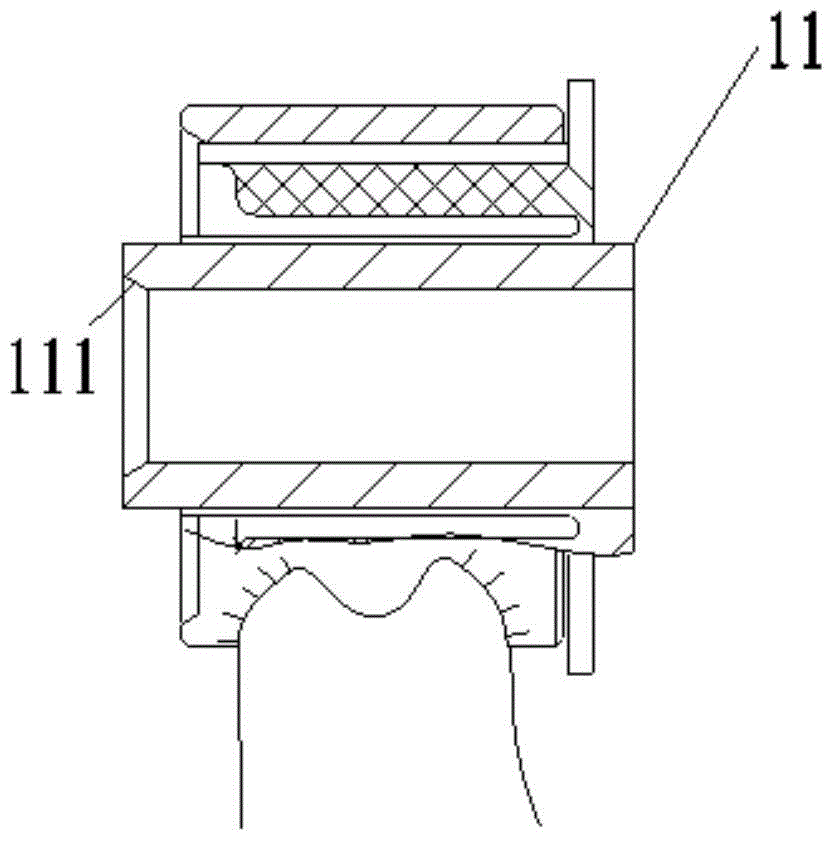

[0029] The key innovation point of the present invention is to simulate the three-coordinate principle, and the two ends of the combined structure are respectively the common axis of the center points of the outermost rings of the two bushings 11 .

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

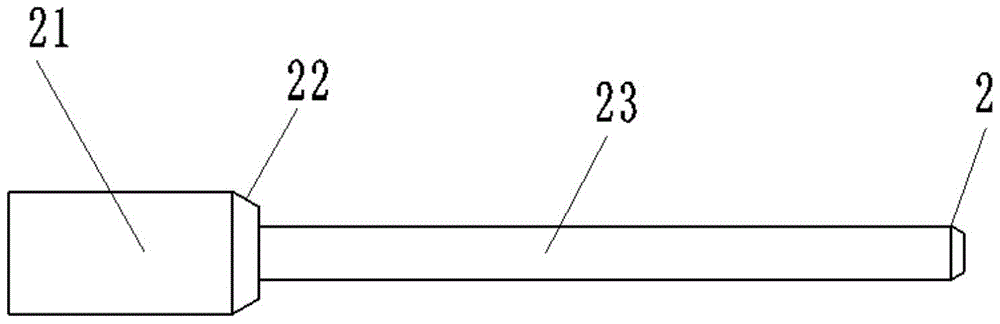

[0031] like image 3 , 4 , 5, the combined long-distance shaft sleeve coaxiality detector includes a sliding end shaft 2, a reference rod 3 and a detection sliding sleeve 4, and there are two sliding end shafts 2, and the sliding end shaft 2 includes a The chamfered fitting part 22 matched with the chamfered part 111 of the bushing also includes a sliding pin part 23 that can extend into the bushing 11;

[0032] Both ends of the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com