Permanent magnet driver

A transmission, permanent magnet technology, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of high power transmission loss rate, high noise and energy consumption, coupler damage, etc., to achieve power transmission loss Low rate, fast response of torque regulation and speed regulation, and excellent energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The magnetic poles of the main end faces of the first permanent magnet 11 and the second permanent magnet 21 are mutually repelled and discharged.

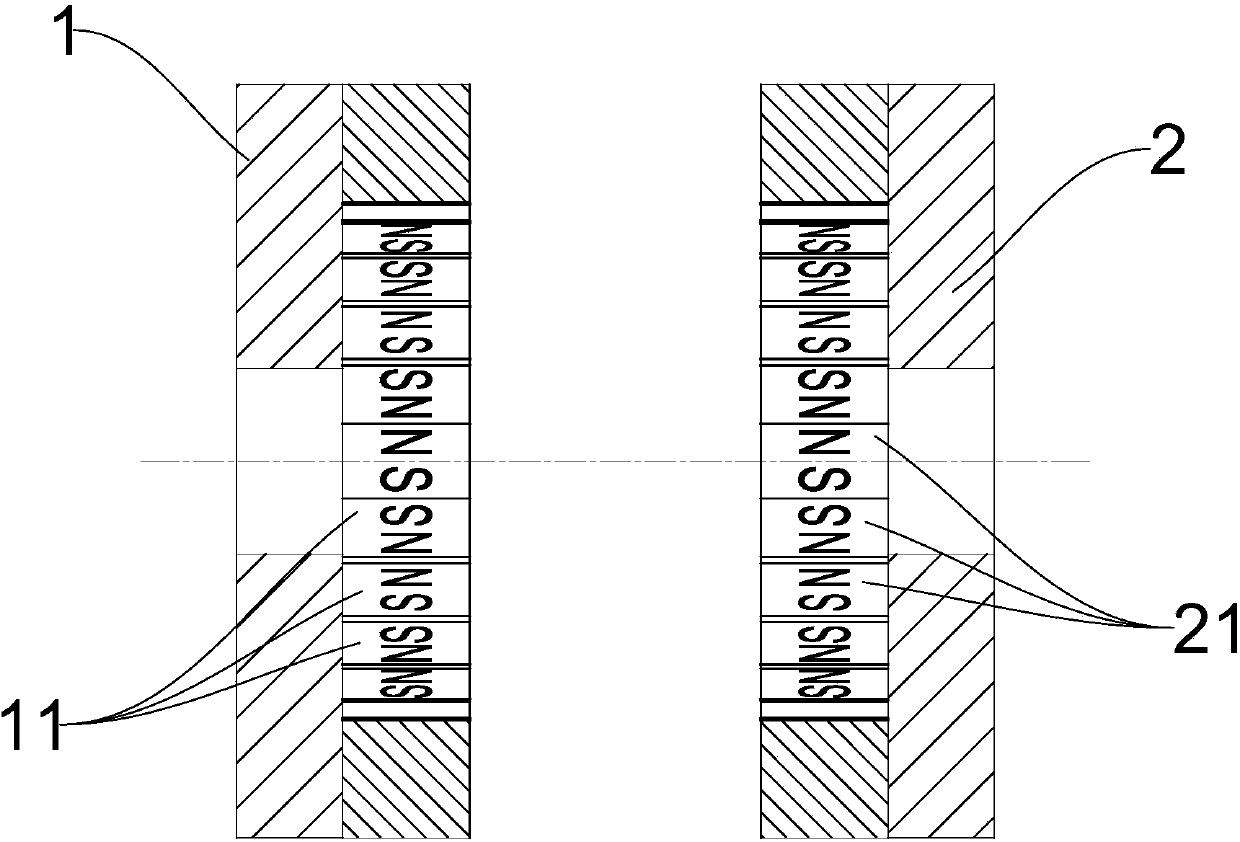

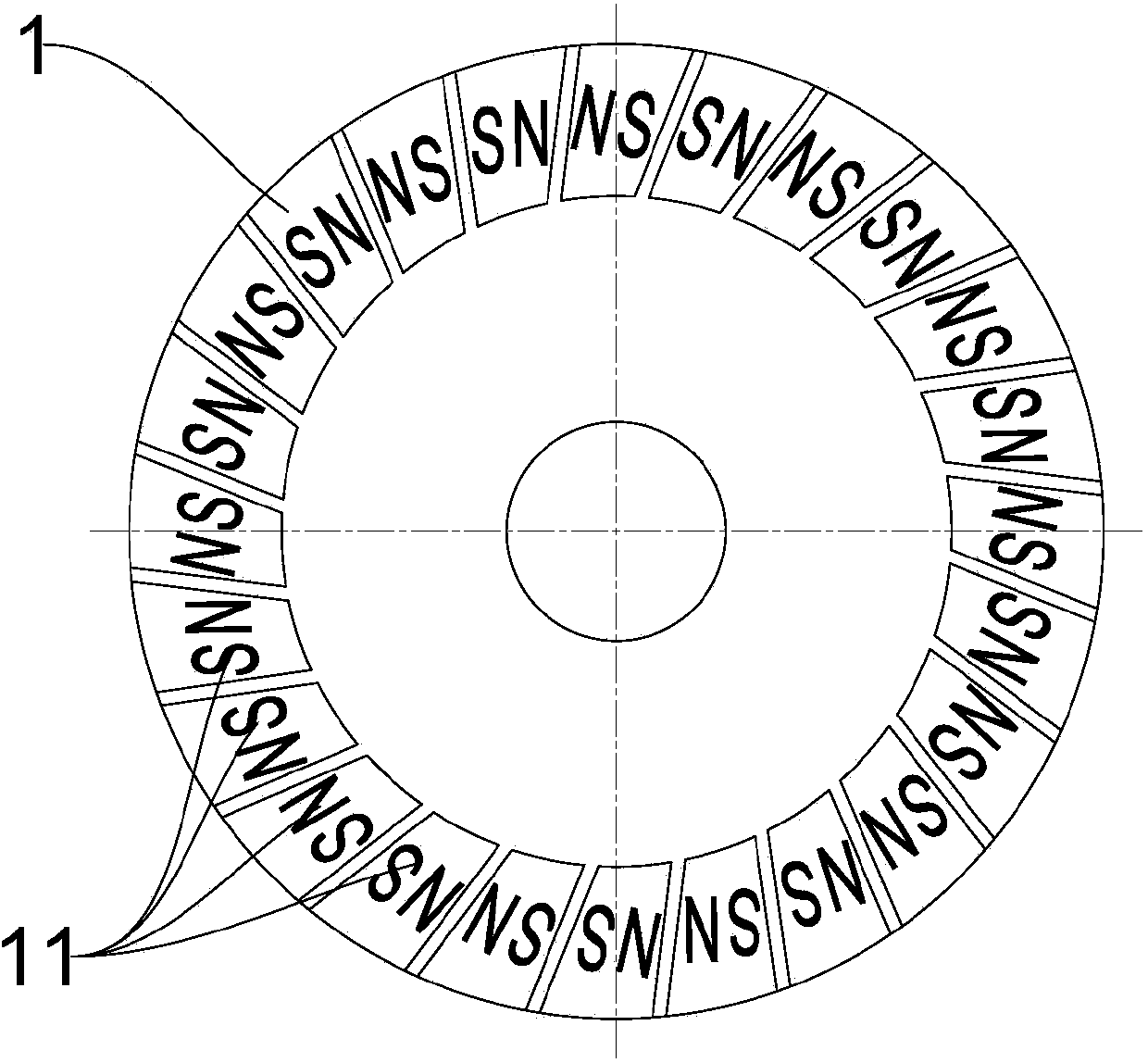

[0074] Such as figure 1 , figure 2 As shown, the first permanent magnet 11 is arranged around the first transmission disc 1, and its side is connected with the first transmission disc 1, and the magnetic poles of the main end faces of the first permanent magnet 11 repel each other to form an arrangement of NS:SN In sequence, a magnetizer is provided between adjacent first permanent magnets 11; the arrangement of the second permanent magnets 21 is the same as that of the first permanent magnets 11 and the first transmission disc 1 and the second transmission disc 2 same size as figure 2 As shown, the first transmission disc 1 and the second transmission disc 2 are as figure 2 Arranged in parallel.

Embodiment 2

[0076] Such as Figure 5 As shown, the first permanent magnet 11 is arranged in a cylindrical shape in the order of NS: SN, which is larger than the diameter of the cylindrical shape of the second permanent magnet 21 arranged in the order of NS: SN, and the cylindrical shape of the second permanent magnet 21 is Arranged on the inner side of the cylinder formed by the first permanent magnet 11 and arranged coaxially, from Figure 13 It can be seen from the figure that the magnetic poles of the main end faces of the first permanent magnets 11 repel each other and form an arrangement sequence of NS:SN, and a magnetizer is arranged between adjacent first permanent magnets 11; the arrangement of the second permanent magnets 21 It is the same as the arrangement of the first permanent magnet 11 .

Embodiment 3

[0078] Such as Figure 6 , Figure 7 As shown, one end-face magnetic pole of the first permanent magnet 11 is connected to the first transmission disc 1 through a magnetizer, and the other end-face magnetic pole is arranged in the order of N:S:N:S; the arrangement of the second permanent magnet 21 is the same as The arrangement of the first permanent magnet 11 is the same; as Figure 6 As shown, the first transmission disk 1 and the second transmission disk 2 are arranged in parallel, so that the end surface magnetic poles of the first permanent magnet 11 and the end surface magnetic poles of the second permanent magnet 21 are arranged oppositely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com