Cleaning vehicle for cleaning welding seams on inner wall of steel storage tank

A technology for cleaning vehicles and storage tanks, which is applied to motor vehicles, cleaning hollow objects, cleaning methods and appliances, etc. It can solve the problems of poor working environment for workers, large cleaning equipment, and physical damage to workers, so as to achieve small size and reduce labor costs. Intensity, the effect of safeguarding physical health and life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

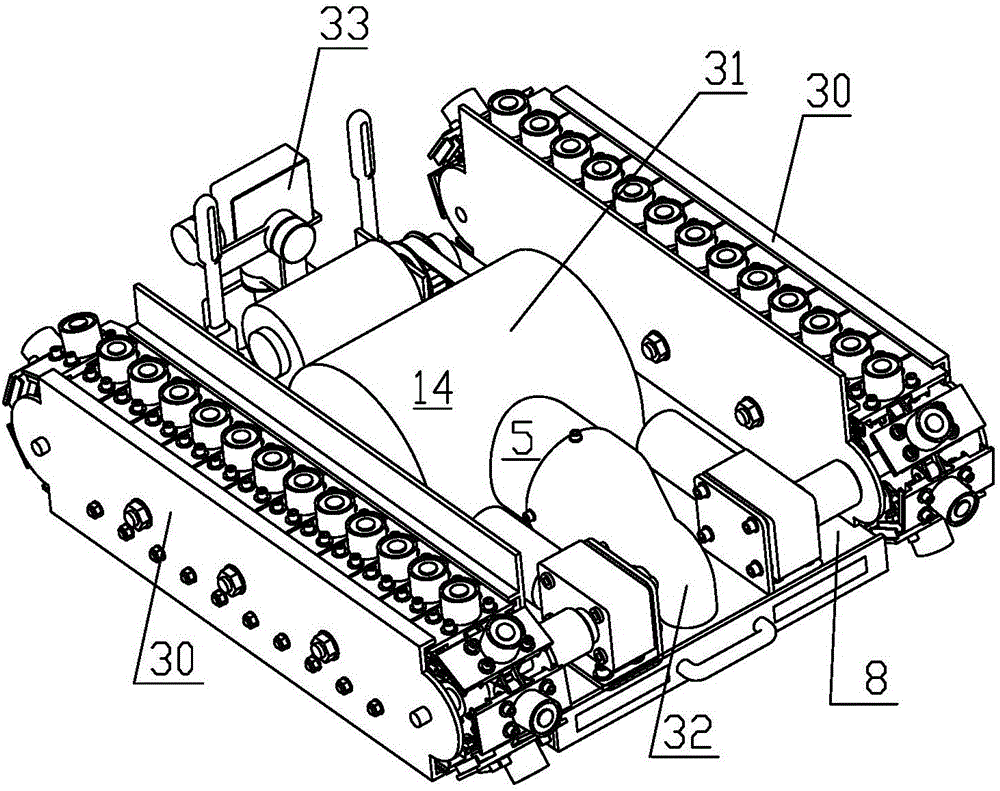

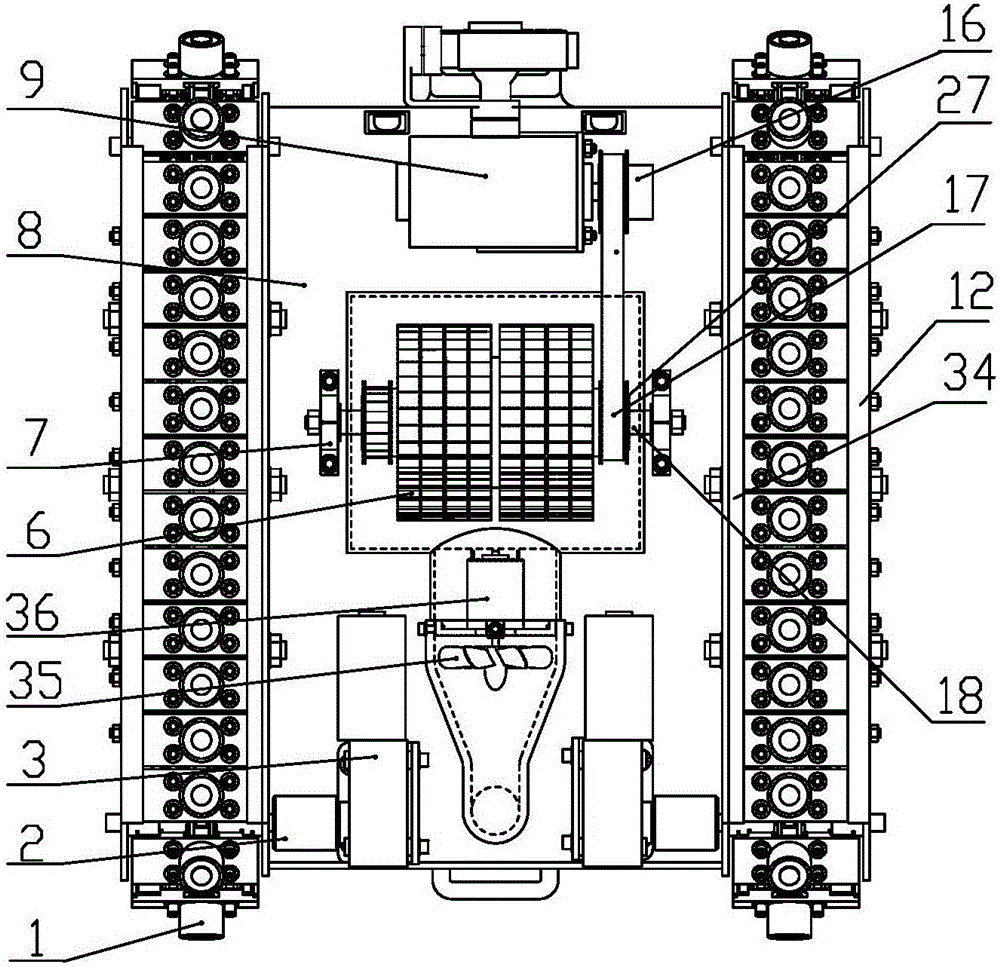

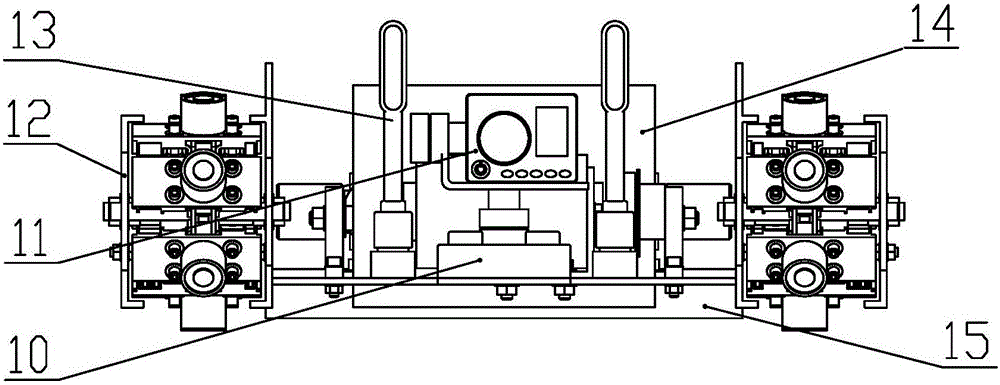

[0046] A cleaning vehicle for cleaning the inner wall weld seam of a steel storage tank according to the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0047] A cleaning vehicle for cleaning the inner wall weld seam of a steel storage tank according to the present invention, two worm gear reducer motors respectively control the movement of the left and right crawlers composed of a plurality of track shoes, so as to realize the forward and backward movement of the cleaning vehicle and turning; the cleaning device is fixed on the chassis of the trolley, powered by a high-power motor, so as to efficiently complete the cleaning task; the dust suction mechanism is also installed on the chassis to collect the dust generated during the cleaning process to form a clean working environment. All motors and electromagnets that provide power are powered by 12V DC batteries, and the working voltage of the cleaning ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com