A method for calcining high-alumina bauxite in a tunnel kiln with variable cross-section

A high-alumina bauxite and tunnel kiln technology, which is applied in the field of calcining high-alumina bauxite, achieves the effects of reasonable space utilization, reduction of masonry materials, and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

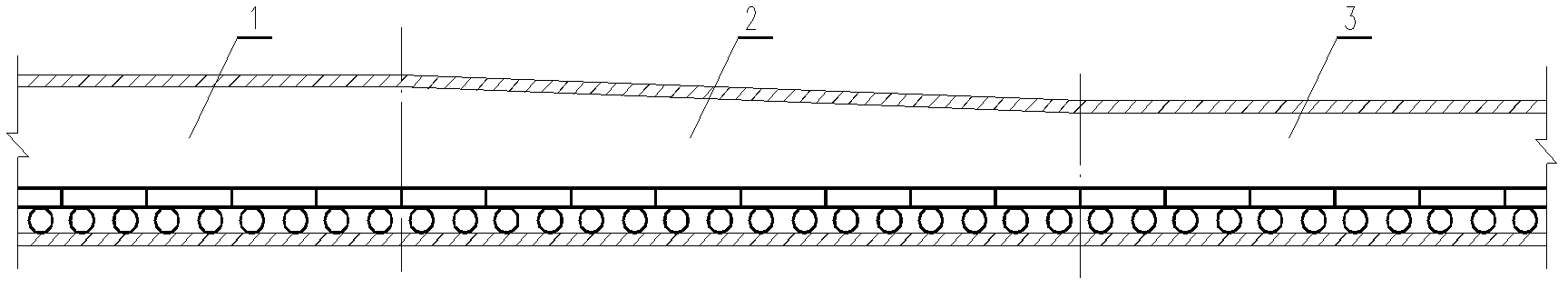

[0015] like figure 1 As shown, the high-alumina bauxite homogenized material is evenly laid on the kiln car of the tunnel kiln, and the kiln car is pushed into the kiln from the kiln head and enters the pre-tropical zone 1. The heat source of the pre-tropical zone is the combustion of fuel flowing in from the calcination zone The generated hot flue gas can make full use of the heat it carries, improve fuel utilization and reduce energy consumption. In the preheating zone, the high-alumina bauxite homogenized material is preheated for 8 to 16 hours, and the temperature is raised to 1450-1750 ° C. After preheating the homogenized material, the temperature of the hot flue gas drops below 250 ° C.

[0016] Then the kiln car enters the calcination zone 2, the kiln roof of this calcination zone is a slope gradual change type, and the kiln roof gradually becomes lower from the preheating zone to the cooling zone, and the total effective height reduction of the kiln is 20% to 40%. Th...

Embodiment 2

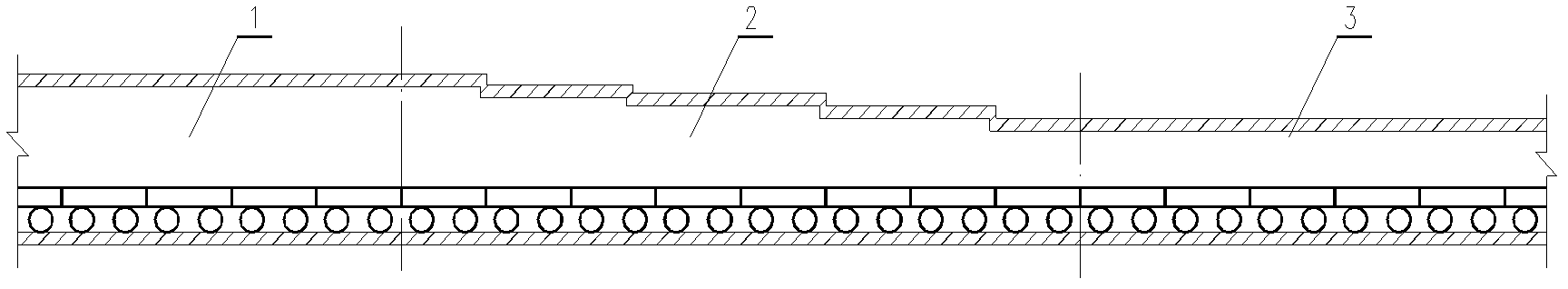

[0019] so figure 2 It shows that the high-alumina bauxite homogenized material is evenly laid on the kiln car of the tunnel kiln, and the kiln car is pushed into the kiln from the kiln head and enters the pre-tropical zone 1. The heat source of the pre-tropical zone is generated by the combustion of fuel flowing from the calcination zone. The hot flue gas can make full use of the heat it carries, improve fuel utilization and reduce energy consumption. In the preheating zone, the high-alumina bauxite homogenized material is preheated for 8 to 16 hours, and the temperature is raised to 1450-1750 ° C. After preheating the homogenized material, the temperature of the hot flue gas drops below 250 ° C.

[0020] Then the kiln car enters the calcination zone 2, the kiln roof of this calcination zone is a stepwise gradual change type, and the total reduction of the effective height of the kiln is 20% to 40%. The high-alumina bauxite is heated and calcined by means of combustion equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com