Semi-active particle damping rubber suspension device for power assembly

A particle damping and powertrain technology, applied in the field of auto parts, can solve the problems of low reliability, high power consumption and high cost, and achieve the effects of simple and reliable structure, convenient manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

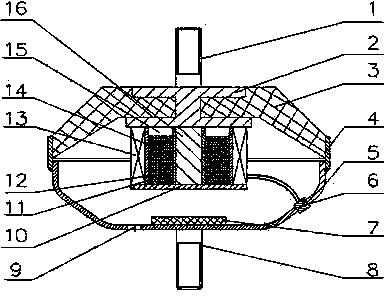

[0028] A powertrain semi-active particle damping rubber mount. Such as figure 1 Shown: the upper connecting bolt 1 of this embodiment is connected with the powertrain, and the lower connecting bolt 8 is connected with the vehicle frame. The upper plane of the connecting frame 2 is fixed with the upper connecting bolt 1, and the middle position of the rubber spring 3 is coaxially embedded in the connecting frame 2. The outer wall of the opening end of the rubber spring 3 is vulcanized and bonded to the steel ring 4, and the opening end of the rubber spring 3 passes through the The steel ring 4 is fixedly connected to the open end of the suspension housing 5 . The inner side of the bottom of the suspension housing 5 is provided with a buffer pad 7 , the housing of the suspension housing 5 is provided with a communication hole 9 , and the outer side of the bottom of the suspension housing 5 is fixed with a lower connecting bolt 8 .

[0029] The lower end of the outer steel pipe...

Embodiment 2

[0040] A powertrain semi-active particle damping rubber mount. Except following technical parameter, all the other are identical with embodiment 1.

[0041]The diameter of the steel ball 14 is 0.1-1mm.

[0042] The material of the rubber spring 3 is nitrile rubber.

[0043] The loaded amount of the steel ball 14 is 60-70% of the volume of the damping cavity 15 .

[0044] The shape of the outer steel pipe 11 and the shape of the inner steel pipe 12 are both oval pipes.

Embodiment 3

[0046] A powertrain semi-active particle damping rubber mount. Except following technical parameter, all the other are identical with embodiment 1.

[0047] The operating voltage of the electromagnetic coil 13 is 24V.

[0048] The diameter of the steel ball 14 is 1-3 mm.

[0049] The material of the rubber spring 3 is neoprene.

[0050] The loaded amount of the steel ball 14 is 70-80% of the volume of the damping chamber 15 .

[0051] The shape of the outer steel pipe 11 and the shape of the inner steel pipe 12 are both polygonal pipes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com