A steel ball type force-limiting safety coupling

A safety coupling and steel ball technology, which is applied in the direction of couplings, sliding couplings, mechanical equipment, etc., can solve the problems of inconvenient use and inconvenience, and achieve the effect of convenient refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

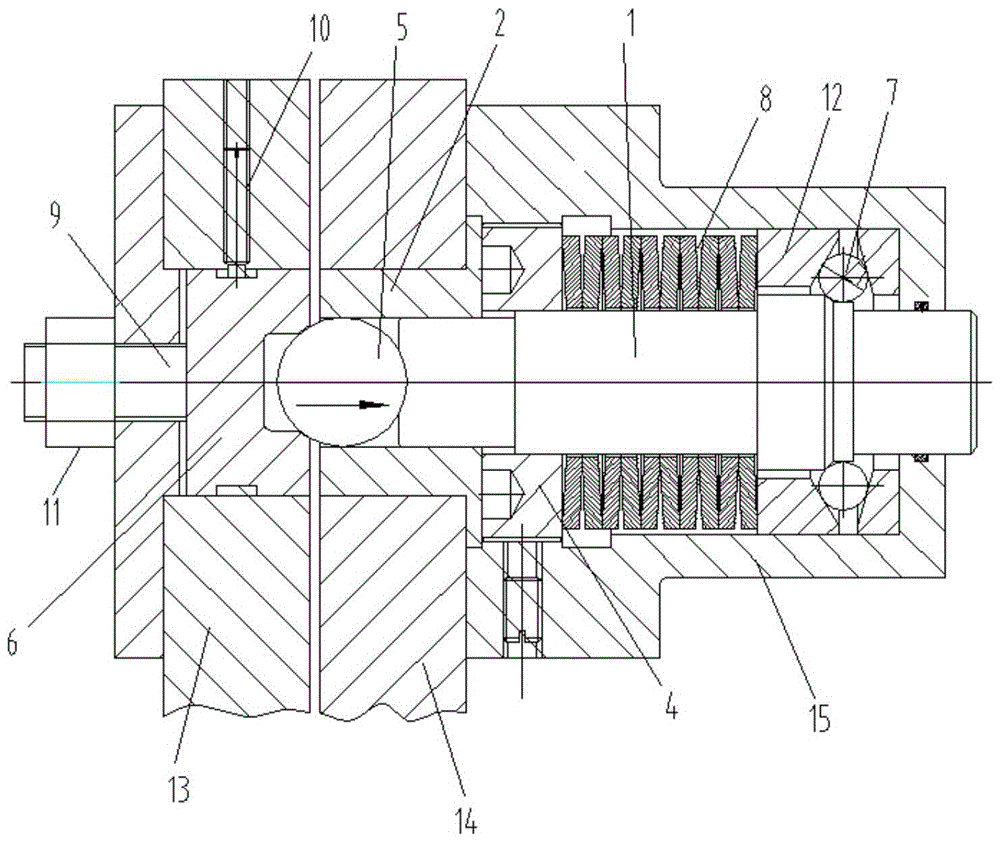

[0017] A steel ball type force-limiting safety coupling of this embodiment, such as figure 2 As shown, it includes a shell, a first flange, a second flange, a centering sleeve, a guide sleeve, a butterfly spring, a steel ball, a steel ball and a guide rod, and the first flange is arranged on the circumferential outside of the centering sleeve , and the centering sleeve is fixedly connected to the shell through fasteners; and the second flange is arranged on the circumferential outside of the guide sleeve, and the centers of the centering sleeve and the guide sleeve are on a straight line, so One end of the butterfly spring is provided with an adjusting nut, and the other end is provided with a spring pressure plate; at the same time, the circumferential outer side of the butterfly spring and the spring pressure plate are slidably connected with the shell, and the guide rod is slidably connected with the butterfly spring and the spring pressure plate, and extend out of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com