Nanocrystalline cellulose (NCC) composite waterborne epoxy resin and preparation method thereof

A water-based epoxy resin and nano-crystal technology, which is applied in the field of nano-microcrystalline cellulose composite water-based epoxy resin and its preparation, to achieve the effects of improving performance, enhancing interaction, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

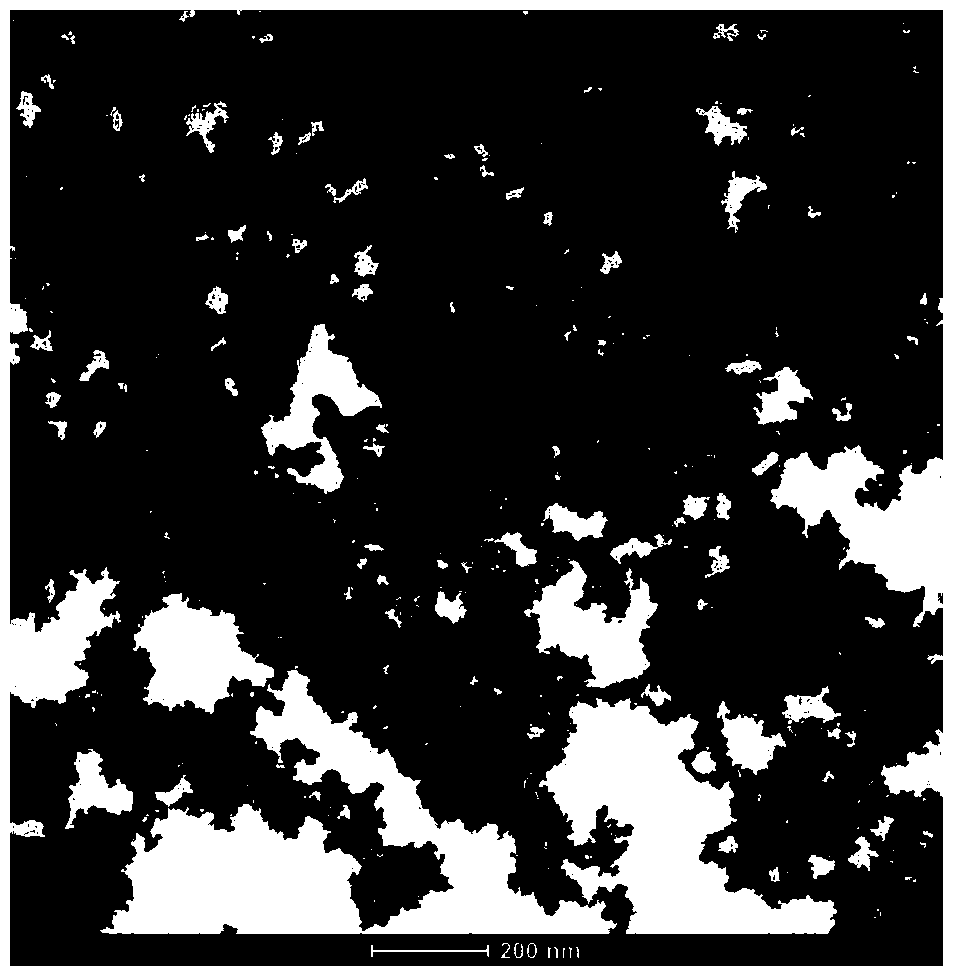

Image

Examples

Embodiment 1

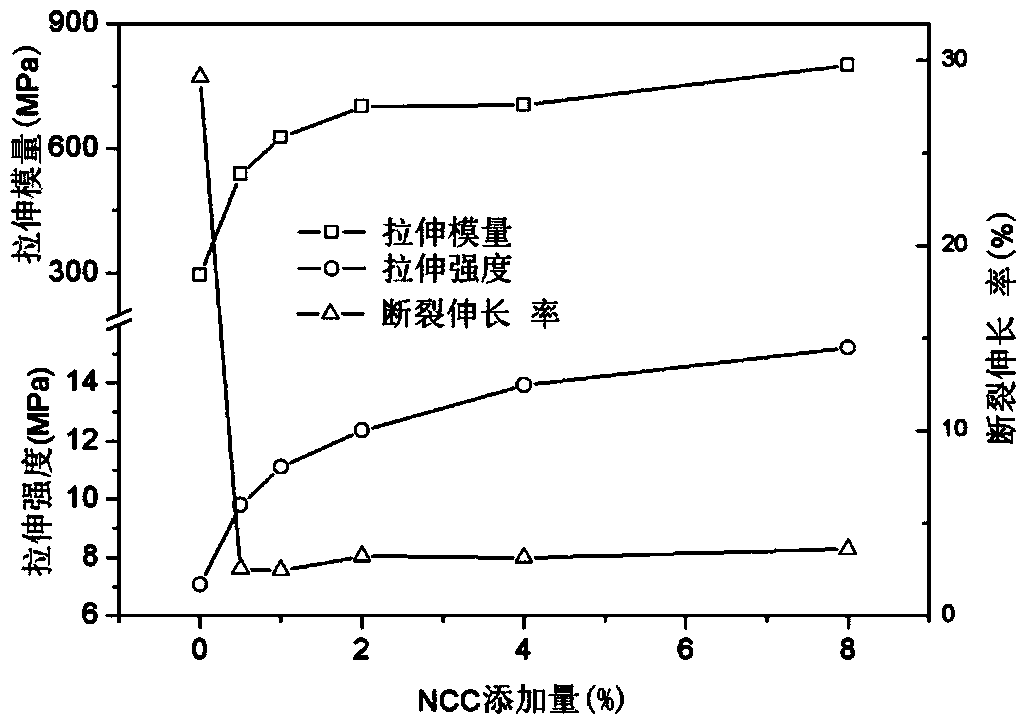

[0026] Example 1: The amount of NCC added is 0.5% of the total mass of the solid resin (water-based epoxy resin and amine curing agent)

[0027] Add 0.6033g of NCC aqueous suspension (3% by mass) to 5.00g of water-based epoxy resin (50% by mass of solid content), stir evenly, and then add 2.80g of amine curing agent (40% by mass of solid content) , Mix evenly, add 7.84g water to dilute, coat the film on the polytetrafluoroethylene plate, put it at room temperature for 2 days, and then bake it in a 90℃ oven for 4h to measure the properties of the composite polymer paint film. The composite product has a tensile modulus of 538.3MPa (25°C), a tensile strength of 9.81MPa (25°C), an elongation at break of 2.54% (25°C), and a storage modulus of 1.074MPa (70°C).

Embodiment 2

[0028] Example 2: The amount of NCC added is 1% of the total mass of the solid resin

[0029] Add 1.207g NCC water suspension (mass percent concentration 3%) to 5.00g water-based epoxy resin (mass percent solid content 50%), ultrasonically vibrate for 20min, then add 2.80g amine curing agent (mass percent solid content 40%) ), mix evenly, add 7.32g of water to dilute, coat the film on the polytetrafluoroethylene plate, put it at room temperature for 2 days, and then bake it in a 90℃ oven for 4h to measure the performance of the composite polymer paint film. The composite product has a tensile modulus of 626.2MPa (25°C), a tensile strength of 11.11MPa (25°C), an elongation at break of 2.46% (25°C), and a storage modulus of 1.362MPa (70°C).

Embodiment 3

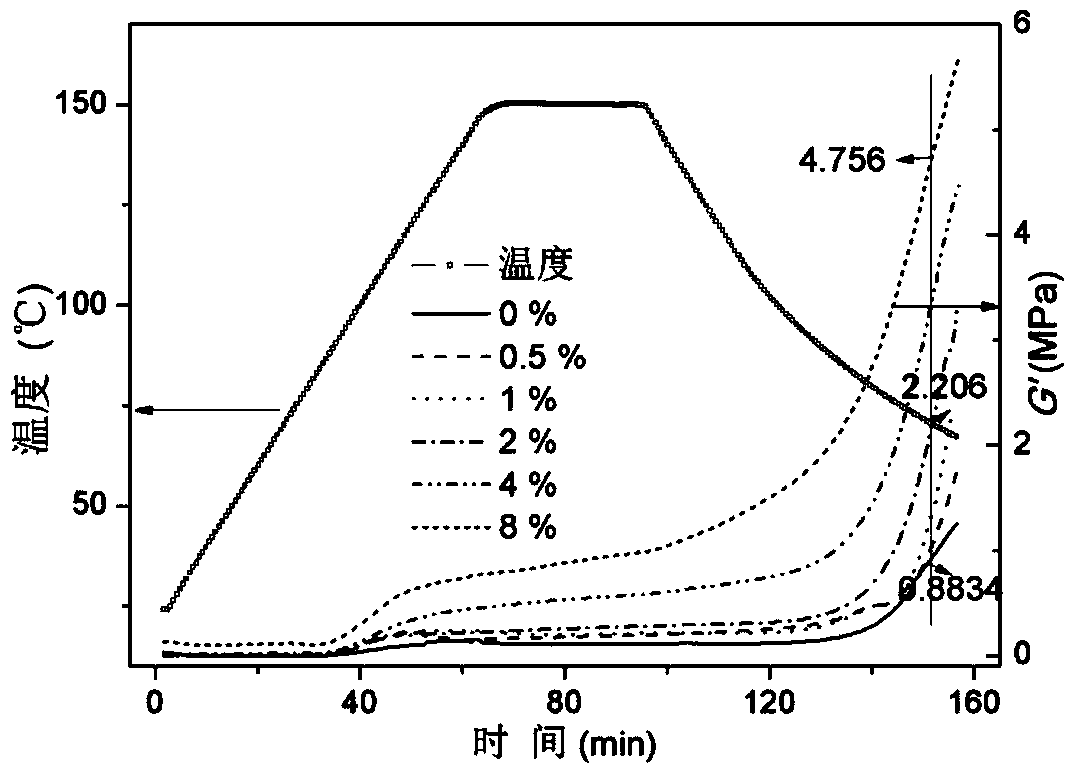

[0030] Example 3: The amount of NCC added is 2% of the total mass of the solid resin

[0031] Add 2.413g of NCC aqueous suspension (3% by mass) to 5.00g of water-based epoxy resin (50% by mass of solid content), stir evenly, and then add 2.80g of amine curing agent (40% by mass of solid content) , mixed evenly, diluted with 6.27g of water, coated on a polytetrafluoroethylene plate, placed at room temperature for 2 days, and then dried in an oven at 90 °C for 4 hours to measure the properties of the composite polymer paint film. The composite product has a tensile modulus of 700.5MPa (25°C), a tensile strength of 12.37MPa (25°C), an elongation at break of 3.21% (25°C), and a storage modulus of 2.206MPa (70°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com