A plastic-coating alloy additive for coating

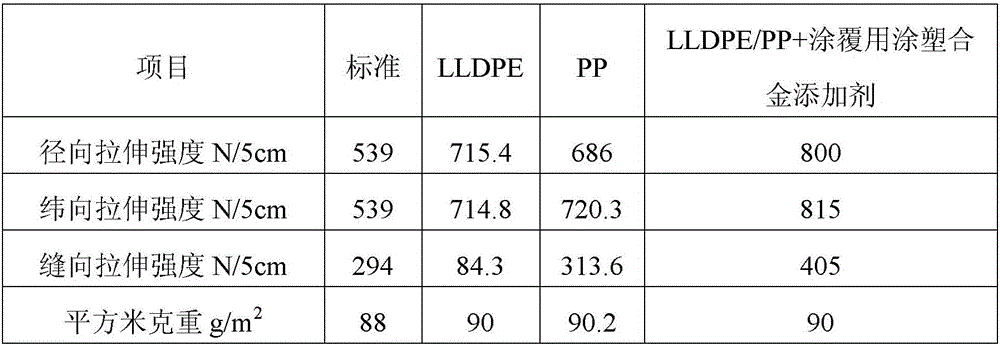

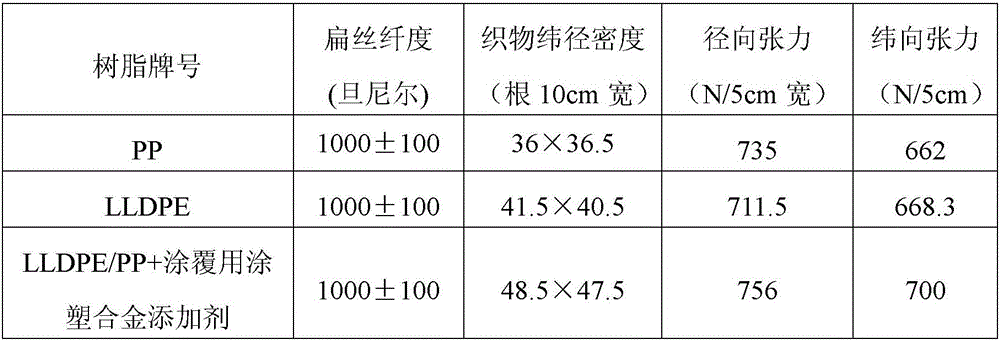

An additive and plastic coating technology, applied in the field of alloy additives, can solve the problems of poor tear, poor tensile strength, poor burst resistance, etc., and achieve the effects of preventing high temperature creep, improving peel strength, and improving peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: This embodiment is a plastic-coating alloy additive for coating, consisting of 22-30 parts of low-density polyethylene, 5-40 parts of ethylene-propylene copolymer, 50-60 parts of inorganic filler, It is prepared by 1-2 parts of lubricant, 1-2 parts of coupling agent, 1-2 parts of heat stabilizer, 0.25-0.31 part of cross-linking agent, 0.2-1 part of antioxidant and 0.2-1 part of light stabilizer.

[0009] The plastic-coating alloy additive for coating described in this embodiment is prepared according to the following steps:

[0010] 1. Weighing: Weigh 22-30 parts of low-density polyethylene, 5-40 parts of ethylene-propylene copolymer, 50-60 parts of inorganic filler, 1-2 parts of lubricant, 1-2 parts of coupling agent, 1 to 2 parts of heat stabilizer, 0.25 to 0.31 part of crosslinking agent, 0.2 to 1 part of antioxidant and 0.2 to 1 part of light stabilizer;

[0011] 2. Inorganic filler activation: Add 50-60 parts of inorganic filler, 1-2 parts...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the low density polyethylene has a molecular weight of 100,000 to 300,000. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the melt flow rate of the ethylene-propylene copolymer is 120 g / 10 min. Others are the same as those in Embodiment 1 or 2.

[0021] The ethylene-propylene copolymer described in this embodiment is prepared by using ethylene monomer and propylene monomer as raw materials, using a metallocene catalyst as a catalyst, and preparing the molar ratio of ethylene monomer to propylene monomer at 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com