Water-absorbing acrylic ester foam material and preparation method and applications thereof

A technology of acrylate and foam materials, applied in the field of water-absorbing materials, can solve the problems of low reaction rate, high reaction activity, poor selectivity, etc., and achieve production stability, high absorption rate, and prolong curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

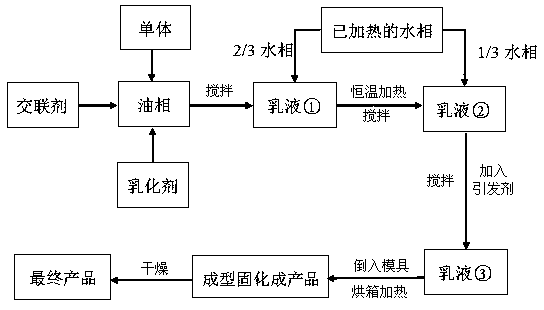

Image

Examples

Embodiment 1

[0048] 1. Preparation of water-absorbent acrylate foam

[0049] (1) To prepare the oil phase system, weigh 7.2g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, Tween-80 1.3g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 9:1.

[0050] (2) Prepare the water phase system, weigh 0.096g of calcium chloride, add water to 480g to dissolve, at this time, the mass fraction of the electrolyte is 0.02%, and it is ready for use.

[0051] (3) Prepare the initiator phase, weigh 0.66g of TEMPO, add water to 10g to dissolve, and set aside.

[0052] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and keep the stirring speed above 800 rpm, then add the evenly stirred oil phase into the three-necked flask, and wait for the emulsion to become Before it becomes viscous, add 160g of ...

Embodiment 2

[0056] 1. Preparation of water-absorbent acrylate foam

[0057] (1) To prepare the oil phase system, weigh 5.6g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, Tween-80 1.3g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 7:1.

[0058] (2) Prepare an aqueous phase system, weigh 0.48g of calcium chloride, add water to 480g to dissolve it, at this time, the mass fraction of the electrolyte is 0.1%, and it is ready for use.

[0059] (3) Prepare the initiator phase, weigh 0.5g of TEMPO, add water to 10g to dissolve, and set aside.

[0060] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and keep the stirring speed above 800 rpm, then add the evenly stirred oil phase into the three-necked flask, and wait for the emulsion to become Before it becomes viscous, add 160g of...

Embodiment 3

[0064] 1. Preparation of water-absorbent acrylate foam

[0065] (1) To prepare the oil phase system, weigh 8.8g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, Tween-80 1.3g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 11:1.

[0066] (2) Prepare the water phase system, weigh 4.8g of calcium chloride, add water to 480g to dissolve, at this time, the mass fraction of the electrolyte is 1%, and it is ready for use.

[0067] (3) Prepare the initiator phase, weigh 0.8g of TEMPO, add water to 10g to dissolve, and set aside.

[0068] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and keep the stirring speed above 800 rpm, then add the evenly stirred oil phase into the three-necked flask, and wait for the emulsion to become Before it becomes viscous, add 160g of water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com