Small and medium dual-hole HKUST-1 material and preparation method and application thereof

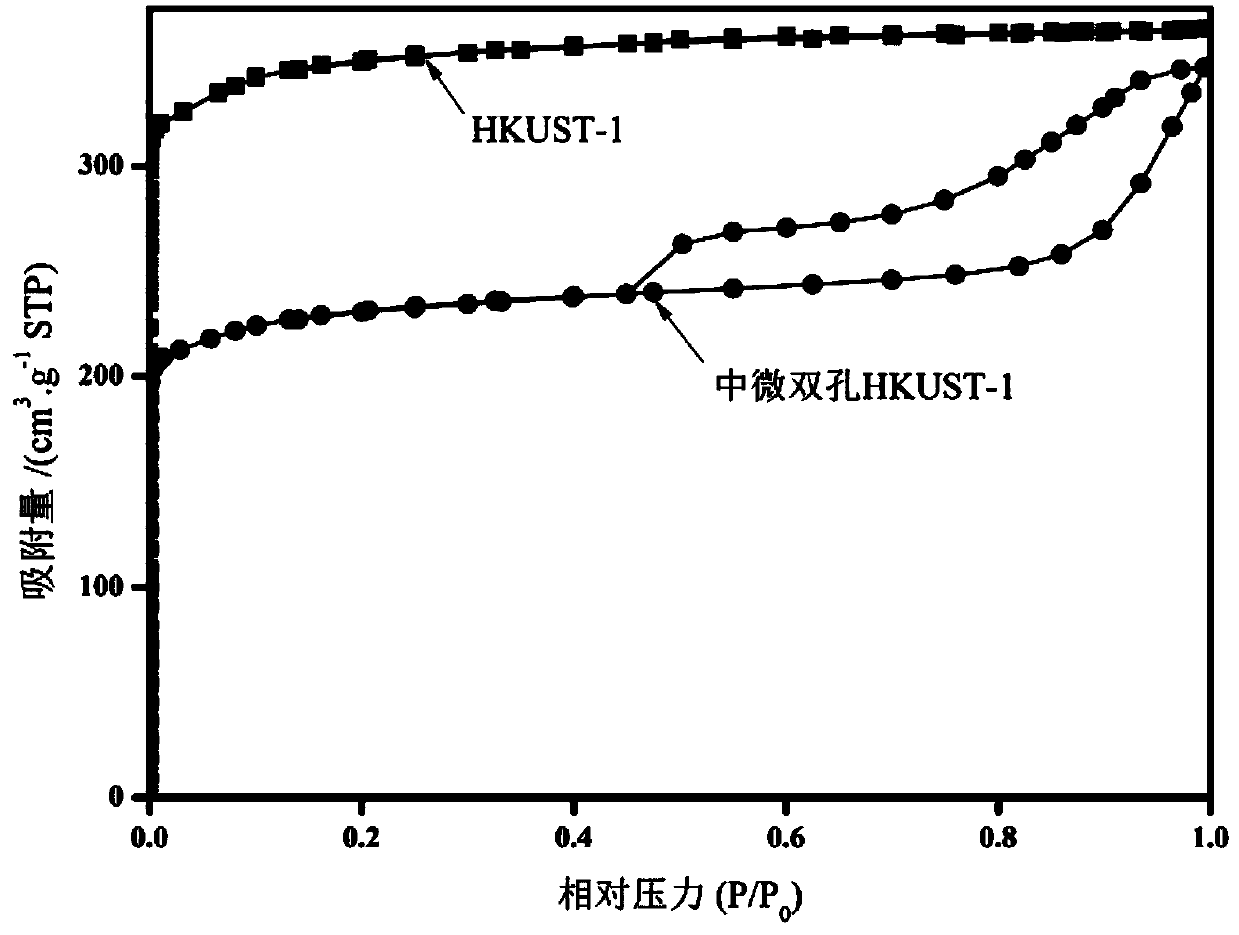

A kind of HKUST-1, medium and micro double-pore technology, applied in chemical instruments and methods, other chemical processes, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of increased synthesis cost, reduced pore size, long-term limit Ligand method is widely used to achieve the effect of good crystal structure, good repeatability, rich micropore and mesopore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 1.068g Cu(NO 3 ) 2 .3H 2 O was dissolved in a solvent formed by mixing 8ml DMF, 8ml ethanol and 8ml water, and stirred until completely dissolved to obtain a clear solution A; another 0.46g H 3 BTC was dissolved in the same solvent formed by mixing 8ml DMF, 8ml ethanol and 8ml water, and stirred until completely dissolved to obtain a clear solution B; add the clear solution B to the clear solution A, and stir evenly to obtain a mixed solution; 0.197g3 -APS was added to the mixed solution, and then stirred for 30 minutes; the mixed solution was transferred into a stainless steel autoclave for hydrothermal synthesis, and heated at 110°C for 12h; after cooling to room temperature, the product was filtered and vacuum-dried at 150°C for 8h; Soak and wash with ethanol 4 times at 100°C for 12 hours each time; filter the product and dry it in vacuum at 150°C for 12 hours to prepare sample B1 of medium-micro-porous HKUST-1 material.

Embodiment 2

[0041] Weigh 1.068g Cu(NO 3 ) 2 .3H 2 O was dissolved in a solvent formed by mixing 8.5ml DMF, 8.5ml ethanol and 8.5ml water, and stirred until completely dissolved to obtain a clear solution A; another 0.50g H 3 Dissolve BTC in the same solution formed by mixing 8.5ml of DMF, 8.5ml of ethanol and 8.5ml of water, and stir until completely dissolved to obtain a clear solution B; add the clear solution B to the clear solution A, and stir evenly to obtain a mixed solution; Add 0.16g of 3-APS into the mixed solution, and stir for 60min; transfer the mixed solution into a stainless steel autoclave for hydrothermal synthesis, and heat at 120°C for 8h; after cooling to room temperature, the product is filtered and vacuum-dried at 120°C for 15h ; The product was soaked with ethanol at 150° C. for 3 times, each time for 14 hours; the product was filtered and vacuum-dried at 140° C. for 8 hours to obtain a sample B2 of medium-micro-porous HKUST-1 material.

Embodiment 3

[0043] Weigh 1.068g Cu(NO 3 ) 2 .3H 2 O was dissolved in a solvent formed by mixing 8.5ml DMF, 8.5ml ethanol and 8.5ml water, and stirred until completely dissolved to obtain a clear solution A; another 0.45g H 3 Dissolve BTC in the same solvent formed by mixing 8.5ml DMF, 8.5ml ethanol and 8.5ml water, stir until completely dissolved to obtain clear solution B; add clear solution B to clear solution A, stir evenly to obtain a mixed solution; Add 0.32g of 3-APS into the mixed solution, and stir for 50 minutes; transfer the mixed solution into a stainless steel autoclave for hydrothermal synthesis, and heat at 110°C for 10h; after cooling to room temperature, the product is filtered and vacuum-dried at 140°C for 15h The product was soaked with ethanol at 120°C for 5 times, each time for 8h; the product was filtered and vacuum-dried at 120°C for 15h to obtain a sample B3 of medium-micro-porous HKUST-1 material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com