Loading and palletizing host for bagged cement truck loader

A vehicle loader and palletizing technology, applied in the field of palletizing hosts, can solve the problems of unfavorable health of workers, poor working environment of workers, high labor intensity of workers, etc., and achieve the effects of simple structure, low cost and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

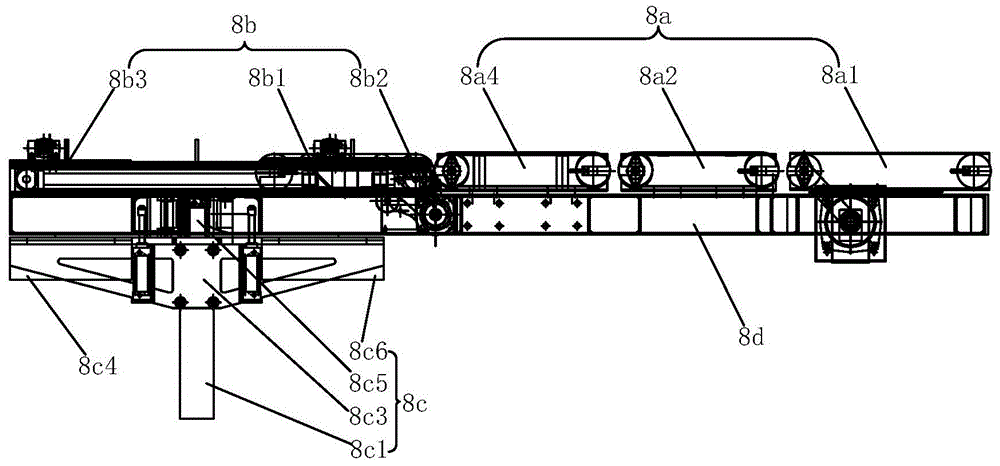

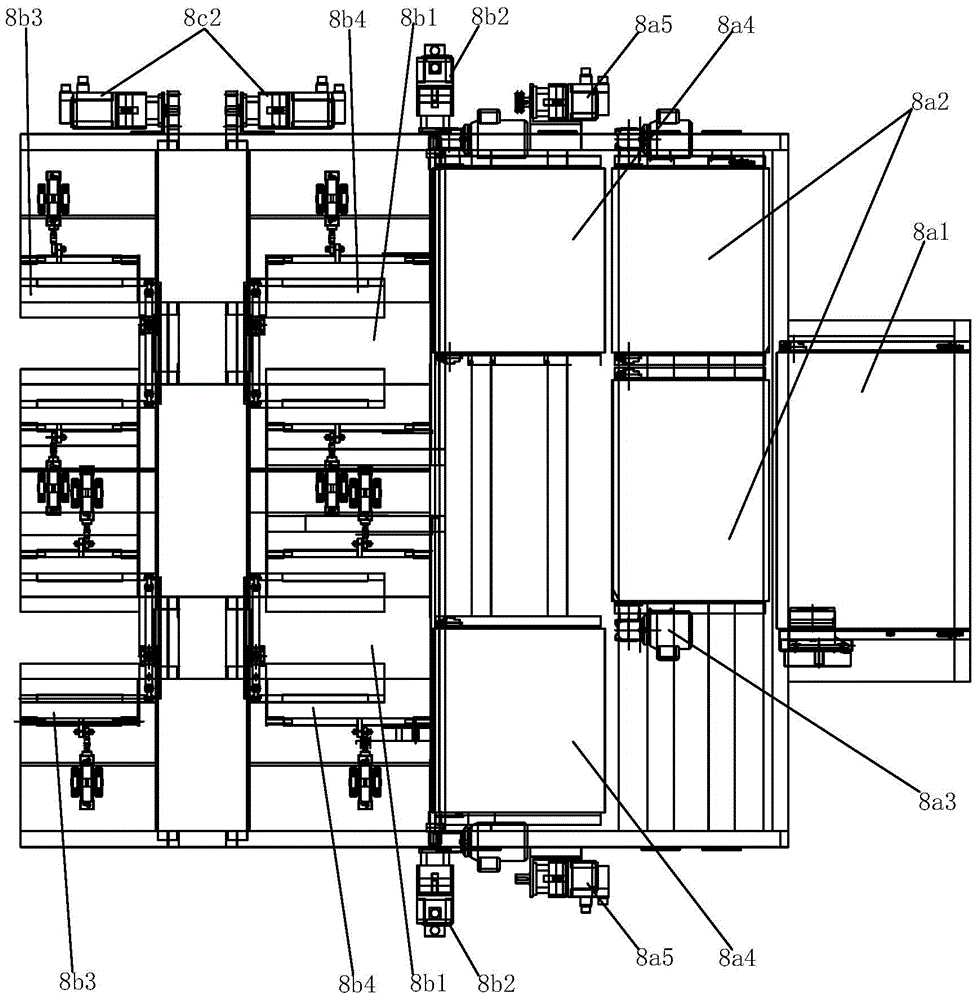

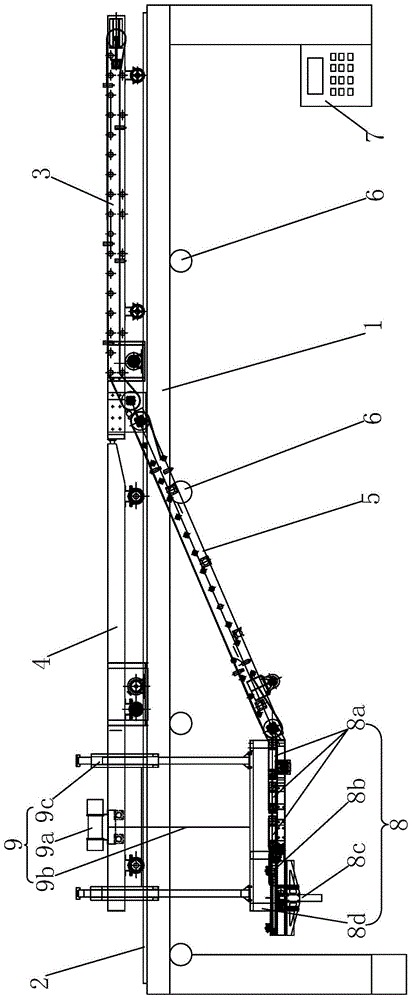

[0047] When this loading and palletizing host is actually used, it needs to cooperate with the controller 7, the positioning system 6, the inclined conveying device 5, the walking device 4, the horizontal conveying device 3 and the guide rail 2 to form a fully automatic bagged cement loading machine to realize bagging. Fully automatic loading of cement, specifically, the fully automatic bagged cement loading machine includes a guide rail 2 fixed on the factory building 1, a horizontal conveying device 3 rolled on the guide rail 2, and a horizontal conveying device 3 rolled on the guide rail 2 The walking device 4 connected to the output end of the horizontal conveying device 3, the inclined conveying device 5, the positioning system 6 and the controller 7, the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com