A production coating process and online processing device for a three-piece pop can plate

A coating process and treatment device technology, which is applied in the post-processing of printing, printing devices, general parts of printing machinery, etc. The effect of film performance improvement and coating operation efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

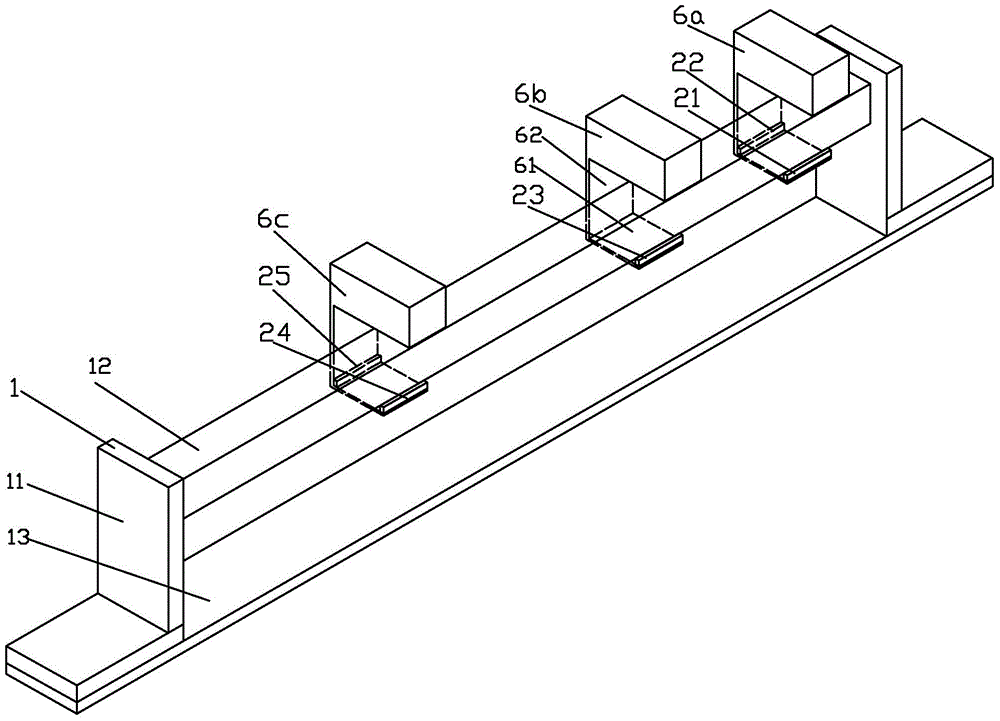

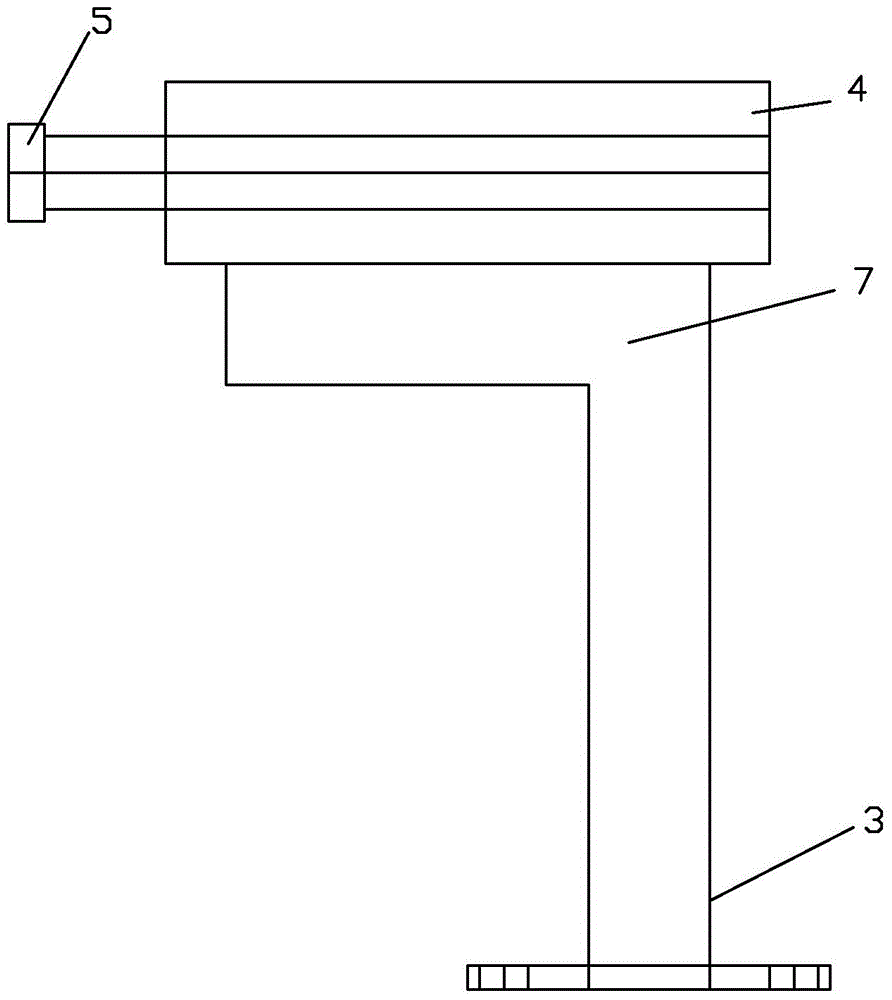

[0053] The present invention relates to a production and coating process for three-piece cans, which is used to produce a certain brand of functional beverage cans (250ml). The base material is tinplate, the hardness is T4, and the amount of tin plating is 1.1 / 2.8g / m 2 (ie inner surface 2.8g / m 2 , the outer surface is 1.1g / m 2 ), the tinplate specification is 0.20mm*858mm*1036mm, and its production process includes the following steps: tinplate preparation, primer coating, baking and curing, UV color printing, and a double-coating process. The double-coating process includes the following steps:

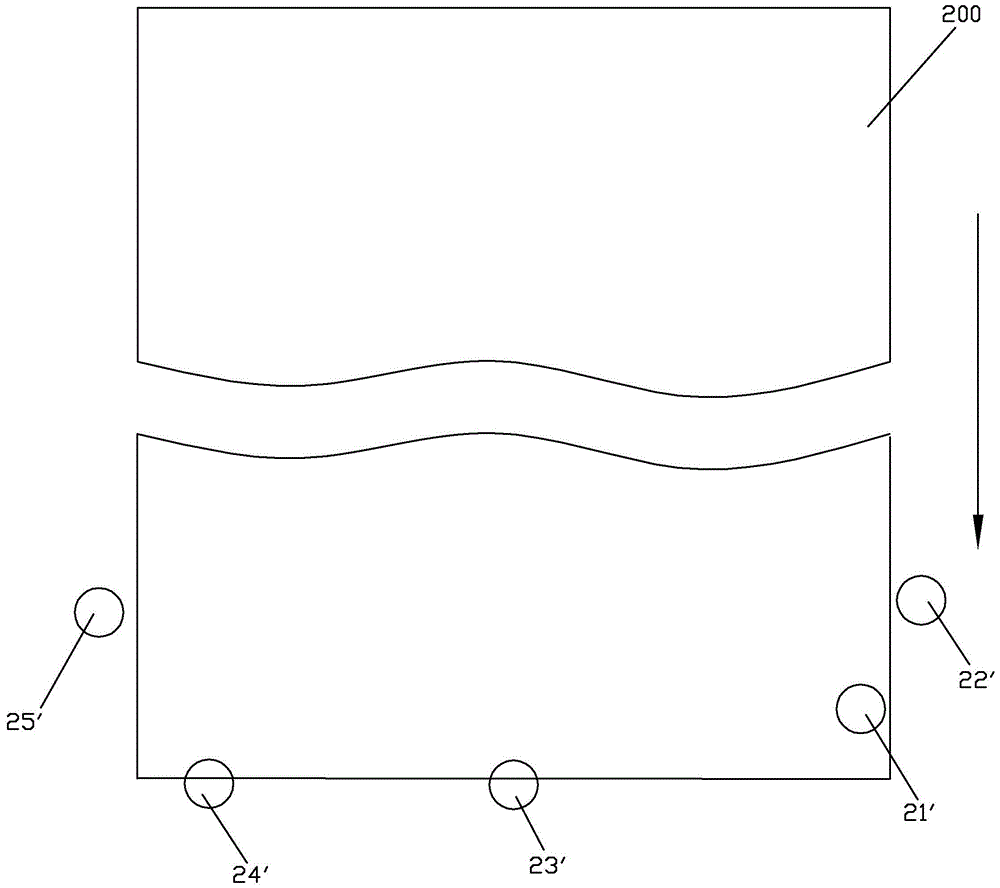

[0054] 1) Feeding: Place the color-printed iron stack (a stack of iron includes 1200 color-printed products) after UV color printing on the feeding power roller table of the coating machine, and pass the color-printed products through the rear-end suction nozzle on the feeding head. Separation, and then the color printing products are transferred to the conveying platform by the suc...

Embodiment 2

[0065] The production and coating process of the three-piece cans of the present invention is to produce a 113D aluminum cover of a beverage can, using an aluminum sheet with a thickness of 0.23 mm as the base material for production, and the production process includes the following steps: aluminum sheet preparation, UV color printing , also includes a double-coating process, the double-coating process includes the following steps:

[0066] 1) Feeding: Put the color-printed iron stack (a stack of iron includes 1400 color-printed products) after UV color printing on the feeding power roller table of the coating machine, and the color-printed products are passed through the rear end suction nozzle on the feeding head. The products are separated, and then the color printing products are transferred to the conveying platform by the suction nozzle at the front end of the feeding head;

[0067] 2) One-time positioning: the color printed product is sent to the first coating unit of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com